Choosing the Right Thermal Spray Materials for Corrosion-Resistant Coatings

Corrosion is one of the most common and destructive forms of material degradation, especially for metals exposed to harsh environments such as marine, chemical, or high-temperature industrial settings. It not only shortens the service life of components but also leads to costly maintenance, equipment downtime, and potential safety hazards. Thermal spray coatings offer an effective strategy for protecting surfaces against corrosion by depositing a controlled layer of material that can resist chemical attack, wear, and thermal stress. These coatings work by either forming a dense physical barrier or using electrochemical principles, such as the sacrificial anode method. In this article, we discuss the selection of Thermal Spray Materials for Corrosion-Resistant Coatings, highlighting their properties, applications, and best practices for industrial use. Readers will gain insights into material performance, environmental adaptation, and coating techniques to maximize component longevity.

At Advanced Powder Tech, we specialize in high-quality thermal spray material products, ensuring optimal performance for industrial and scientific applications.

What Are Thermal Spray Materials for Corrosion-Resistant Coatings?

Thermal spray materials are metallic, ceramic, or cermet powders, wires, or rods that are melted or semi-melted and deposited onto a substrate to form a protective coating. For corrosion-resistant applications, the choice of material directly determines coating performance in terms of chemical stability, adhesion, and mechanical durability. These materials can protect metals either by forming an inert barrier against aggressive chemicals or by acting as a sacrificial layer that corrodes preferentially, preserving the underlying substrate.

Common Thermal Spray Materials for Corrosion Resistance:

| Material Type | Properties | Typical Applications | Advantages |

| Zinc (Zn) | Sacrificial protection, good adhesion | Steel structures, bridges | Low cost, reliable protection |

| Aluminum (Al) | Oxidation-resistant, lightweight | Aerospace components, tanks | Long-term corrosion protection, minimal maintenance |

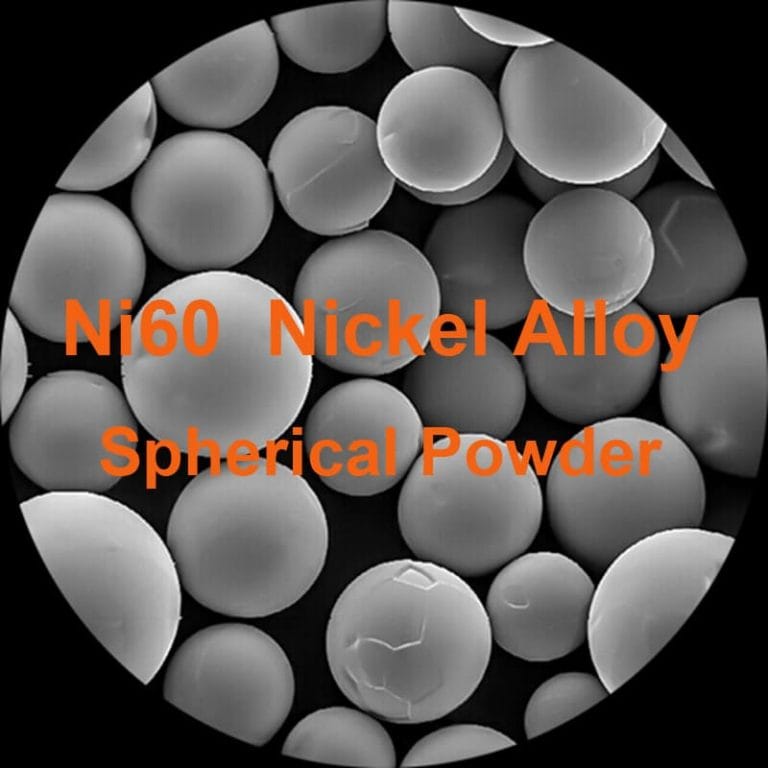

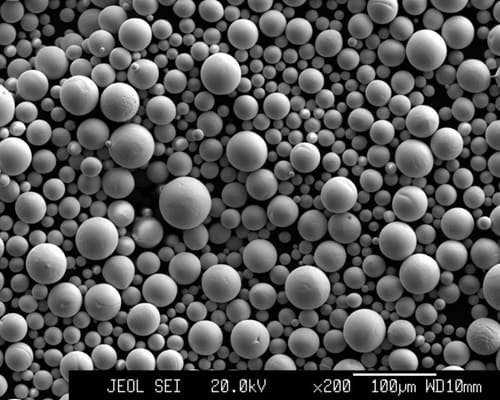

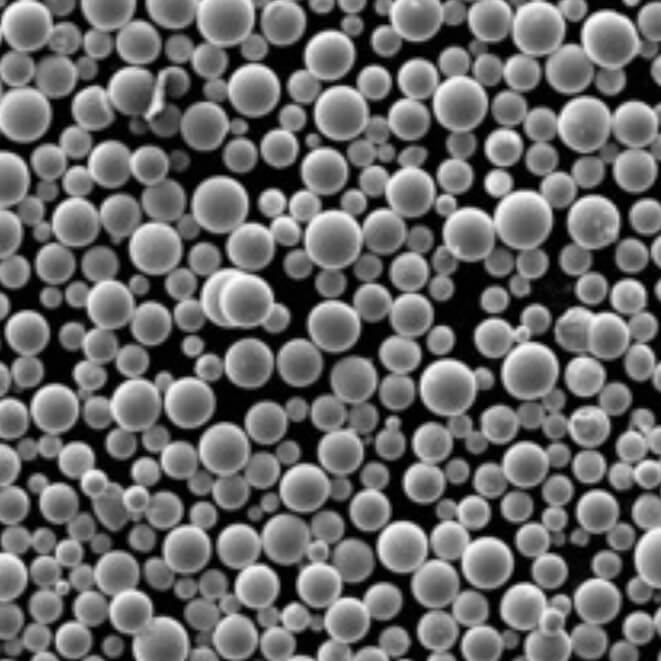

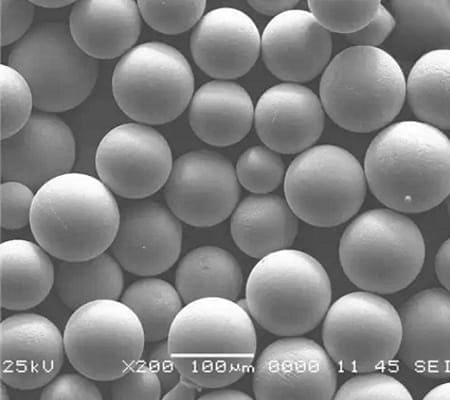

| Nickel alloys | High corrosion and chemical resistance | Chemical processing equipment | Suitable for acids and alkalis |

| Ceramic oxides (Cr2O3, Al2O3) | Hard, inert, wear-resistant | Pump parts, valves | High temperature and chemical stability |

| Cermets (WC-Co) | High hardness, moderate corrosion resistance | Mining and slurry pipelines | Wear and moderate corrosion protection |

By understanding these materials’ properties, engineers can select coatings based on the expected corrosive environment, operating temperature, and mechanical stress.

Explore our high-quality thermal spray material products.

Why Is Surface Preparation Crucial for Thermal Spray Coatings?

Surface preparation plays a critical role in determining the adhesion and longevity of thermal spray coatings. Without proper preparation, coatings may delaminate, allowing corrosion to penetrate and reducing the overall protection effectiveness. Cleaning, roughening, and pre-treatment are necessary to ensure the coating bonds uniformly and forms a dense, protective layer.

Key Surface Preparation Methods:

- Grit blasting: Increases surface roughness to improve mechanical bonding.

- Degreasing: Removes oils, contaminants, and residues that interfere with adhesion.

- Chemical etching: Prepares metals prone to oxidation by removing passive layers.

- Pre-heating the substrate: Enhances adhesion and reduces residual stress in coatings.

- Sealing: Post-spray sealing reduces porosity and improves chemical resistance.

Proper surface preparation ensures a durable bond between the coating and substrate, which is particularly important in aggressive chemical, marine, and high-temperature environments.

Which Thermal Spray Coatings Are Best for High-Temperature Corrosion?

High-temperature environments, such as industrial furnaces, combustion chambers, and chemical reactors, require coatings that resist both oxidation and chemical degradation. Materials must form stable oxides, maintain mechanical strength, and resist cracking under thermal cycling.

Thermal Spray Materials for High-Temperature Corrosion Resistance:

| Material | Maximum Service Temperature | Advantages | Typical Application | Notes |

| Cr2O3 | 1000°C | Excellent oxidation resistance | Furnace components, valve seats | Dense ceramic barrier, minimal porosity |

| NiCr | 1100°C | Corrosion and thermal stability | Heat exchangers, turbine parts | Can handle moderate wear |

| Al2O3 | 1200°C | Hard, inert, wear-resistant | Kiln linings, high-temp seals | Excellent dielectric properties |

| FeCrAl | 1050°C | Oxidation-resistant, ductile | Burner nozzles, hot gas ducts | Maintains flexibility at high temp |

| NiAl | 1150°C | Oxidation and sulfidation resistance | Gas turbine parts | Combines thermal and chemical protection |

These materials are selected based on their thermal stability, porosity, and ability to form protective oxide layers that slow corrosion under extreme conditions.

How Does Sacrificial Anode Protection Work in Thermal Spray Coatings?

Sacrificial anode coatings protect metals by using materials with more negative electrochemical potentials than the substrate. The sacrificial metal corrodes first, preserving the underlying structure. This method is especially effective for steel and iron in marine and industrial environments where electrolytes are present.

Electrochemical Potentials of Common Sacrificial Metals:

| Materials | Standard Electrode Potential (V) | Corrosion Behavior | Typical Use |

| Zinc (Zn) | -0.76 | Sacrificial protection | Marine steel, bridges |

| Aluminum (Al) | -1.66 | Lightweight corrosion protection | Aerospace, pipelines |

| Magnesium (Mg) | -2.37 | Aggressive environments | Underground tanks, seawater structures |

| Tin (Sn) | -0.14 | Minor sacrificial effect | Electronics, mild protection |

| Nickel (Ni) | -0.25 | Passive layer formation | Chemical tanks, acidic environments |

Using sacrificial coatings in combination with barrier layers can provide dual protection, combining electrochemical and physical corrosion prevention.

Request a custom quote for our thermal spray material products.

Which Corrosion-Resistant Coatings Are Suitable for Acidic or Alkaline Environments?

The chemical composition of the environment heavily influences material selection. Coatings must resist attack from acids, alkalis, oxidizing agents, and salts. Choosing the right material reduces degradation, prevents contamination, and extends service life.

Material Recommendations for Various Chemical Environments

- Nitric Acid: Stainless steel or nickel-based coatings

- Sulfuric Acid: Nickel alloys, titanium coatings

- Hydrofluoric Acid: Monel, nickel-based cermets

- Alkalis (NaOH, KOH): Ni-Al alloys, Cr2O3 ceramics

- Sea Water & Salt Spray: Zinc, aluminum sacrificial coatings with topcoat

- Organic Acids: Al2O3, Cr2O3 ceramic coatings

Proper selection ensures that coatings provide both chemical resistance and mechanical durability in challenging environments.

How Do Porosity and Coating Thickness Affect Corrosion Resistance?

Porosity and thickness are critical for coating effectiveness. High porosity can allow corrosive agents to reach the substrate, while improper thickness can lead to cracking, spalling, or insufficient protection. Optimizing these parameters ensures long-term durability.

Recommended Coating Thickness and Porosity for Corrosion Resistance

| Material | Recommended Thickness (µm) | Target Porosity (%) | Notes |

| Zn | 100-150 | <5 | Sacrificial protection |

| Al | 120-200 | <3 | Marine and high-temp applications |

| Ni alloys | 150-300 | <2 | Chemical processing equipment |

| Cr2O3 | 200-400 | <1 | Abrasion + chemical resistance |

| WC-Co | 150-300 | 3-5 | Moderate corrosion, high wear |

Maintaining low porosity and optimal thickness significantly improves barrier performance and prevents early coating failure.

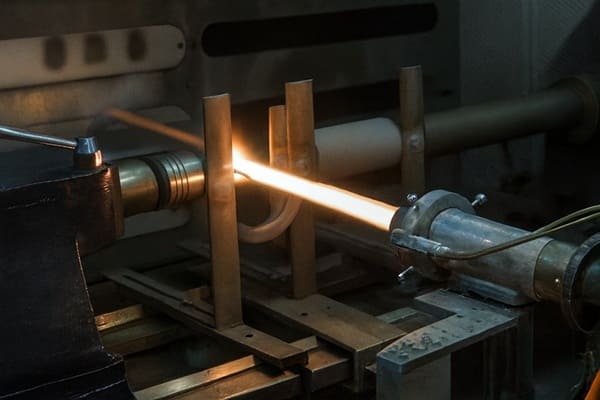

Which Thermal Spray Methods Are Most Effective for Corrosion-Resistant Coatings?

Different thermal spray techniques produce coatings with varying adhesion, density, and surface finish. Selecting the right deposition method ensures optimal performance in specific environmental conditions.

Common Thermal Spray Methods for Corrosion Resistance

- Plasma Spray: High temperatures, suitable for ceramics and metals

- High-Velocity Oxy-Fuel (HVOF): Produces dense, low-porosity coatings for metals and cermets

- Wire Arc Spray: Cost-effective, moderate corrosion resistance

- Flame Spray: Simpler, lower-temperature applications

- Cold Spray: Minimal oxidation, high-density metal coatings

Matching the coating method to the material and environment is crucial to achieving long-term corrosion protection.

FAQ

| Question | Answer |

| Can thermal spray coatings repair corroded metal parts? | Yes, with proper surface preparation and compatible coating material. |

| Which thermal spray material is best for marine environments? | Zinc and aluminum sacrificial coatings, often with an epoxy topcoat. |

| Is high porosity acceptable in corrosion-resistant coatings? | No, higher porosity reduces barrier effectiveness and allows chemical penetration. |

| How thick should a NiCr coating be for chemical resistance? | Essential: poor preparation leads to premature failure and reduced protection. |

| Can ceramic coatings withstand both high temperature and chemical attack? | Yes, materials like Cr2O3 and Al2O3 provide combined thermal and chemical protection. |

| Do thermal spray coatings change substrate dimensions? | Slightly, but the thickness is controllable based on process parameters. |

| Is surface preparation important? | Essential; poor preparation leads to premature failure and reduced protection. |

Conclusion

Selecting the right Thermal Spray Materials for Corrosion-Resistant Coatings is essential to extending the service life of metals and critical industrial components. Considerations include environmental conditions, coating material properties, deposition methods, thickness, porosity, and surface preparation. High-temperature, acidic, alkaline, and marine environments demand careful material selection, ranging from metals and alloys to ceramics and cermets. Applied correctly, thermal spray coatings provide a durable, cost-effective solution to prevent corrosion, minimize maintenance, and ensure operational reliability across industries. By combining scientific material selection with precise application techniques, manufacturers can achieve superior protection and optimize long-term performance.

Looking for high-quality thermal spray materials? Contact us today!