Thermal Interface Materials: The Role of Fillers in Enhancing Efficiency

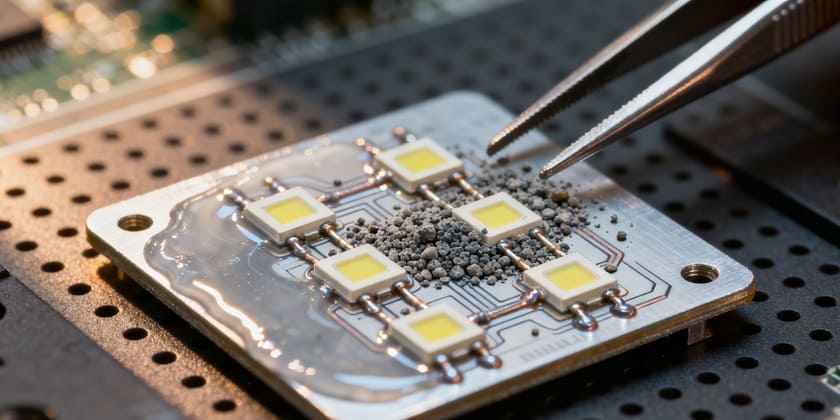

Thermal Interface Materials (TIMs) play a decisive role in modern electronics, power modules, LEDs, and high-density ceramic assemblies where excess heat must be managed reliably. As device power increases and form factors shrink, conventional polymer matrices no longer meet performance targets alone. This is where fillers become essential—improving thermal conductivity, mechanical strength, long-term reliability, and stability under harsh conditions.

This article provides a structured, SEO-optimized exploration of how fillers influence TIM performance. It covers definitions, functions, filler types, mechanisms, ceramic relevance, comparisons, applications, future trends, and an FAQ table. The goal is to help engineers, material scientists, and buyers understand why filler-engineered TIMs are critical for the next generation of ceramic-based systems.

At Advanced Powder Tech, we specialize in high-quality powder products, ensuring optimal performance for industrial and scientific applications.

What Are Thermal Interface Materials and Why Do They Need Fillers?

Thermal Interface Materials are compounds designed to reduce thermal resistance between two surfaces, such as a ceramic substrate and a heat spreader. However, most polymer or grease matrices have very low thermal conductivity—typically between 0.1 and 0.3 W/m·K. To overcome this limitation, high-performance fillers are incorporated to form conductive pathways.

Understanding why fillers matter requires examining both the physical limitations of the matrix and the engineering demands of advanced devices. As ceramic components (AlN substrates, Si3N4 modules, Al2O3 boards) move into high-power applications, TIMs must match their heat dissipation needs.

Common Thermal Conductivities

| Material | Typical Thermal Conductivity (W/m·K) |

| Silicone/Polymer Matrix | 0.1–0.3 |

| Alumina (Al2O3) Filler | 20–30 |

| Aluminum Nitride (AlN) Filler | 140–180 |

| Hexagonal Boron Nitride (BN) | 200–400 (in-plane) |

| Silver Particles | ~430 |

| Graphite/Graphene | 500–1500 |

Fillers raise overall conductivity by orders of magnitude.

Without these high-performance ceramic or carbon fillers, TIMs would fail to meet the requirements of power modules, EV inverters, IGBT ceramics, and high-brightness LED assemblies.

Explore our high-quality powder products.

How Do Fillers Improve Thermal Conductivity in Thermal Interface Materials?

Thermal conductivity enhancement is the primary reason fillers are added to TIMs. Pure polymer matrices cannot efficiently transfer heat, while engineered fillers create continuous thermal pathways.

The effectiveness depends on filler loading, geometry, aspect ratio, and contact network density. Ceramic fillers such as BN and AlN excel because they provide strong conductivity while maintaining electrical insulation—critical for many ceramic substrates.

Filler Influence on Conductivity

| Parameter | Effect on TIM Performance |

| Filler Volume Fraction | Higher loading → higher conductivity (optimal 60–90%) |

| Filler Geometry | Platelets > spheres > irregular particles |

| Particle Size Distribution | Multi-modal distributions pack more efficiently |

| Surface Treatment | Silane coatings improve interface bonding |

The combination of thermal network formation and improved interfacial bonding is what enables TIMs to reach 5–10 W/m·K and beyond.

Ceramic-based fillers offer stability, insulation, and reliability, making them indispensable for power ceramic assemblies.

Why Are Ceramic Fillers Important for Mechanical Strength in Thermal Interface Materials?

TIMs must maintain structure under pressure, vibration, or thermal cycling. Polymer matrices alone deform easily, while ceramic fillers reinforce the matrix and prevent mechanical failure.

In gasketing and bonding applications, mechanical integrity is essential to keep the interface intact over thousands of cycles.

Mechanical Benefits of Fillers

- Prevent cracking under high pressure

- Increase modulus and stiffness

- Reduce pump-out during thermal cycling

- Improve cohesive strength for long-term bonding

After incorporating high-performance fillers like Al2O3 or BN, TIMs exhibit better resistance to deformation and improved thickness stability.

This is especially important for ceramic-based power modules, where bond-line control influences system reliability.

How Do Fillers Reduce Thermal Resistance in Thermal Interface Materials?

Thermal resistance is influenced not only by thermal conductivity but also by filler packing, interfacial contact, and bond-line thickness.

The right filler design helps TIMs conform to micro-roughness on ceramic or metal surfaces, creating more contact points and reducing heat-blocking voids.

Key Strategies for Reducing Resistance

| Strategy | Description |

| High Filler Loading | Creates many conductive channels |

| Multi-Modal Fillers | Improves packing efficiency |

| Surface Coating | Enhances bonding to the polymer |

| Anisotropic Fillers | Directs heat flow toward critical paths |

Optimized resistance is essential to allow ceramics such as Si3N4 and AlN to operate near their performance limits without overheating.

A well-designed filler system can cut total thermal resistance by 30–70% compared to unfilled polymer TIMs.

How Do Fillers Enhance Stability and Reliability in Thermal Interface Materials?

TIMs often operate in harsh environments such as high temperature, humidity, or continuous thermal cycling. Fillers, particularly ceramic fillers, improve chemical and thermal stability.

For example, BN and Al2O3 fillers resist oxidation and degradation at temperatures far above typical polymer decomposition points.

Stability Advantages of Fillers

- Resistance to thermal oxidation

- Reduced pump-out during cycling

- Improved adhesive strength

- Enhanced resistance to moisture and chemicals

These advantages enable TIMs to survive long-term exposure in automotive, aerospace, and semiconductor packaging environments.

Ceramic components rely on stable TIM performance because fluctuating interface properties can compromise device safety.

What Types of Fillers Are Most Useful in Thermal Interface Materials?

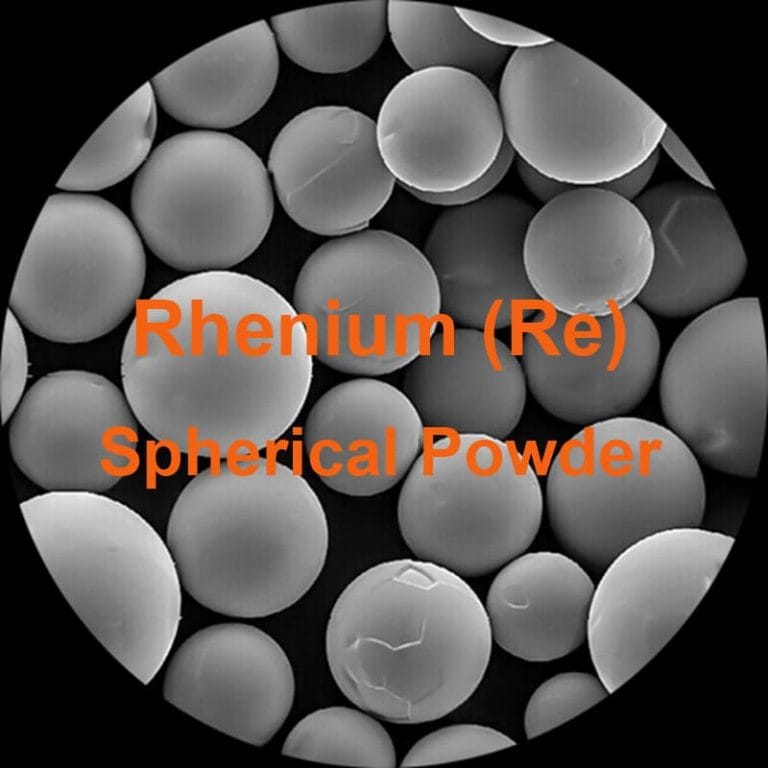

Different fillers address different performance requirements. Ceramic, metallic, and carbon-based fillers each offer unique thermal and structural benefits.

Ceramics remain the most popular in electrically insulated applications, whereas metal and carbon fillers are favored for extreme conductivity.

Common Filler Categories

| Filler Type | Example Materials | Primary Benefits |

| Ceramic | BN, Al2O3, AlN, SiC | High thermal conductivity & insulation |

| Metallic | Ag, Cu, Al | Very high conductivity, but conductive electrically |

| Carbon-Based | Graphite, CNT, graphene | Ultra-high conductivity, lightweight |

Choosing fillers requires balancing cost, electrical requirements, processability, and required conductivity.

Ceramic fillers dominate LED packaging, chip modules, and high-voltage ceramics due to their insulation and reliability.

How Do Thermal Interface Materials Compare with Different Ceramic Substrates?

Ceramic substrates have different thermal and mechanical characteristics, influencing what type of TIM formulation works best.

AlN provides very high conductivity, while Al2O3 offers cost efficiency but lower heat transfer capability.

Comparison Table

| Ceramic Material | Conductivity (W/m·K) | Recommended TIM Filler |

| Al2O3 | 20–30 | Al2O3, BN |

| AlN | 140–180 | BN, AlN |

| Si3N4 | 70–90 | BN, graphite hybrid |

| Sapphire | ~35 | BN, ceramic composites |

Matching TIM filler chemistry to ceramic substrate type minimizes mismatch stress and enhances long-term reliability.

Choosing the right combination also helps reduce interfacial resistance and improves total system performance.

Request a custom quote for our powder products.

How Do Thermal Interface Materials Compare with Other Heat Transfer Solutions?

TIMs compete with thermal pads, solders, greases, and phase-change materials. Each has advantages depending on temperature requirements and mechanical conditions.

Fillers help TIMs close performance gaps with metallic interfaces while offering flexibility and ease of application.

Comparison

| Solution | Conductivity | Electrical Properties | Mechanical Characteristics |

| Filled TIM | 1–10+ W/m·K | Insulating | Soft, comfortable |

| Metal Solder | 20–60+ | Conductive | Brittle |

| Thermal Pads | 1–6 | Insulating | Moderate stiffness |

| Graphite Sheet | 300–500 | Conductive | High anisotropy |

TIMs offer an excellent balance of conductivity, insulation, and mechanical compliance.

For ceramic applications requiring precise insulation and structural flexibility, filled TIMs remain the preferred choice.

What Are the Future Trends for Fillers in Thermal Interface Materials?

As power density increases, TIMs will require more advanced filler technologies. Research is moving toward hybrid fillers combining ceramic and carbon materials, nano-scale structures, and engineered platelet networks.

3D-aligned BN or graphene fillers are becoming promising solutions for next-generation ceramic modules.

Emerging Trends

- Hybrid ceramic-carbon filler systems

- Alignment-enhanced filler networks

- Nano-particle reinforced polymer matrices

- Ultra-high-conductivity (>15 W/m·K) TIMs

Future TIMs will integrate ceramic substrate design, filler engineering, and surface topology to achieve more efficient heat pathways and lower total resistance.

Ceramic-based electronics and power devices will benefit the most from these developments.

FAQ

| Question | Answer |

| Do fillers significantly improve TIM performance? | Yes, fillers can raise thermal conductivity from <0.3 to >10 W/m·K. |

| Are ceramic fillers electrically insulating? | Al2O3, AlN, and BN provide strong insulation and stability. |

| Why is filler loading important? | High volume fractions (60–90%) create conductive networks. |

| Do fillers affect viscosity? | Yes, higher loading increases viscosity and affects processability. |

| Which fillers work best for ceramic substrates? | BN, AlN, and Al2O3 due to thermal stability and insulation. |

Conclusion

Fillers play a fundamental role in determining the performance, reliability, and efficiency of Thermal Interface Materials. By enhancing thermal conductivity, mechanical strength, stability, and heat flow pathways, fillers transform low-conductivity polymers into engineered thermal management solutions. Ceramic fillers—especially BN, AlN, and Al2O3—are central to meeting the demands of power electronics, ceramic substrates, and next-generation semiconductor devices.

As device power density continues to grow, filler-optimized TIMs will remain at the forefront of thermal engineering, ensuring safer, more efficient, and longer-lasting ceramic-based systems.

Looking for high-quality powder product? Contact us today!