Analyzing the Size and Morphology of Bismuth Nanoparticles

In nanotechnology, particle size and morphology are not just physical descriptors—they directly influence the performance and functionality of bismuth nanoparticles (BiNPs). These characteristics affect how BiNPs behave in various fields such as thermoelectric energy conversion, catalysis, biomedical imaging, and nanoelectronics. Smaller particle sizes can enhance surface reactivity and quantum confinement effects, while specific shapes like spheres, rods, or plates impact packing density, surface area, and biological interactions. This article provides an in-depth overview of measurement techniques, data interpretation, synthesis influences, and challenges associated with bismuth nanoparticle characterization. Readers will gain practical insights into controlling these critical properties to maximize the potential of BiNPs across diverse applications.

At Heeger Materials Inc., we specialize in high-quality bismuth spherical powder, ensuring optimal performance for industrial and scientific applications.

What Are Bismuth Nanoparticles and Their Common Applications?

Bismuth nanoparticles typically range from less than 10 nm up to several hundred nanometers. Their distinctive physical and chemical traits make them valuable in numerous industries. Key properties of bismuth nanoparticles are summarized below:

| Property | Typical Value | Significance |

| Particle Size | <10–200 nm | Determines surface area, reactivity, and quantum effects |

| Crystal Structure | Rhombohedral (α-Bi) | Influences electrical and thermal behaviors |

| Density | ~9.78 g/cm³ | High atomic mass suitable for radiological applications |

| Bandgap (Quantum-Confined) | ~1.0–1.5 eV (size-dependent) | Enables tunable optoelectronic properties |

| Surface Area | 10–120 m²/g (size-dependent) | High surface reactivity for catalysis and sensing |

| Melting Point | ~271 °C | Allows low-temperature soldering |

| Thermal Conductivity | ~7.9 W/m·K | Ideal for thermoelectric applications |

| Electrical Conductivity | Moderate (semimetal) | Useful in microelectronics and conductive coatings |

| Toxicity | Low | Safer alternative to lead in biomedical and electronics |

Common Applications:

- Thermoelectrics: Improve energy conversion efficiency by optimizing heat-to-electricity processes.

- Biomedical Imaging: Serve as low-toxicity contrast agents in X-ray and CT scans.

- Catalysis: Enhance reactions such as CO₂ reduction and hydrogenation.

- Nanoelectronics: Used in printed conductive inks, nano-solder pastes, and dielectric layers.

- Antibacterial Coatings: Provide antimicrobial surfaces for medical and industrial use.

Precise control over BiNP morphology and surface chemistry is essential for optimizing these applications, making thorough characterization critical.

Explore our high-quality bismuth spherical powder.

Why Analyze Particle Size and Shape in Nanopowders?

Analyzing size and shape in nanopowders is fundamental for predicting and controlling material performance. Different applications demand specific size uniformity, shape characteristics, and surface properties. Accurate characterization ensures:

- Consistent Quality: Minimizes batch-to-batch variation and improves product reliability.

- Optimized Reactivity: Smaller particles increase surface area, enhancing catalytic and sensing performance.

- Controlled Thermal/Electrical Behavior: Size and anisotropy directly affect these properties.

- Regulatory Compliance: Provides reproducible safety and biocompatibility data for medical or consumer use.

Examples:

- In catalysis, particle size controls reaction kinetics and selectivity.

- Anisotropic shapes can boost thermoelectric performance by influencing the Seebeck coefficient.

- Spherical particles disperse better in biological fluids, improving biomedical applications.

Understanding these factors guides material design and processing for targeted functions.

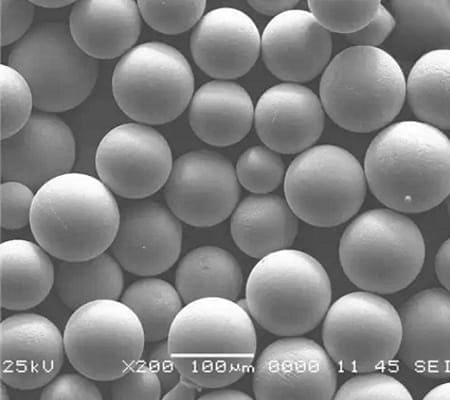

What Techniques Are Used to Measure Particle Size?

Selecting the right measurement technique depends on nanoparticle properties, sample state, and application needs. The following methods are commonly employed:

| Technique | Size Range | Notes |

| Dynamic Light Scattering (DLS) | 1–1000 nm | Fast for colloidal suspensions; sensitive to aggregates |

| Transmission Electron Microscopy (TEM) | 1–500 nm | Direct visualization with sub-nm resolution; time-consuming and costly |

| Scanning Electron Microscopy (SEM) | 10–1000 nm | Effective for surface morphology; less precise for size distribution |

| Atomic Force Microscopy (AFM) | 1–300 nm | Measures height and surface texture; limited scan area |

| X-ray Diffraction (XRD) (Scherrer method) | <100 nm | Estimates crystallite size, not true particle size |

| BET Surface Area Analysis | N/A | Indirect size estimation based on surface area and porosity models |

Combining multiple techniques often yields the most comprehensive understanding of nanoparticle size and morphology.

What Are the Methods for Morphological Characterization?

Morphology encompasses particle shape, aspect ratio, surface texture, and aggregation state. Techniques include:

- TEM and SEM Imaging: Visual assessment of shape and aggregation state.

- Atomic Force Microscopy (AFM): Provides 3D surface topology and roughness data.

- Image Analysis Software (e.g., ImageJ, MATLAB): Quantifies shape parameters like circularity and aspect ratio.

- 3D Tomography (Advanced): Reveals volumetric and internal structure, useful for precision engineering.

For example, rod-shaped BiNPs exhibit anisotropic electrical conductivity, beneficial for nanoelectronic devices.

How Do Synthesis Conditions Affect Particle Size and Shape?

Synthesis parameters play a decisive role in defining the size and morphology of BiNPs. By adjusting these conditions, researchers can achieve nanoparticles tailored for specific applications.

| Synthesis Parameter | Typical Effect on Particle Features |

| Reducing Agent Strength | Faster reducers produce more nuclei, resulting in smaller particles |

| Temperature | Higher temperatures favor larger, more crystalline particles |

| Solvent Polarity | Influences precursor solvation, impacting final morphology |

| Reaction Time | Longer times yield larger grains; shorter times produce smaller particles |

| Surfactants/Additives | Shape control (e.g., rods, plates) and prevention of agglomeration |

Example: BiNPs synthesized with NaBH₄ in water and PVP stabilizer produce ~20 nm spherical particles, while those from glucose in ethylene glycol with CTAB form ~50 nm plate-like structures.

How to Interpret and Report Nanoparticle Morphology Data?

Clear and standardized reporting of morphology data is crucial for reproducibility and comparison. Important metrics include:

- D10/D50/D90 Percentiles: Indicate particle size distribution spread, showing sizes below which 10%, 50%, and 90% of particles fall.

- Mean ± Standard Deviation: Reflects average size and variation, useful for batch comparison.

- Aspect Ratio (AR): Ratio of length to width; values >1 indicate elongated shapes, affecting anisotropic properties.

- Circularity: Measures closeness to a perfect circle (1.0); lower values indicate irregular or elongated shapes.

- Agglomeration Index: Quantifies clustering vs. dispersion; high agglomeration can reduce effective surface area.

Example: A sample with D50 = 25 nm, AR = 1.0, and circularity = 0.95 indicates uniform, spherical, well-dispersed nanoparticles, ideal for consistent application performance.

What Are the Challenges in Measuring Bismuth Nanoparticles?

Despite advanced tools, the measurement of BiNPs faces practical difficulties that can affect data accuracy:

- Oxidation: BiNPs oxidize rapidly upon exposure to air, altering surface and bulk properties. Use inert atmospheres for storage and handling.

- Agglomeration: Nanoparticles tend to form clusters, skewing size measurements. Dispersion techniques like sonication or surfactants help mitigate this.

- Sample Damage in TEM: High-energy electron beams can damage sensitive BiNPs. Low-dose imaging is recommended.

- Representative Sampling: Particle heterogeneity necessitates multiple images and sampling locations to avoid biased results.

Proper management of these challenges is vital for reliable nanoparticle characterization.

How to Choose the Right Size and Morphology of Bismuth Nanoparticles for Your Application

Selecting the appropriate size and morphology depends heavily on the intended application, balancing performance needs with practical constraints. Here are key considerations:

- For Catalysis: Smaller nanoparticles with high surface area increase active sites and boost catalytic efficiency. Plate-like or rod-shaped particles can expose specific crystal facets, enhancing selectivity.

- In Thermoelectrics: Anisotropic shapes, such as rods or plates, can improve charge carrier mobility and thermoelectric performance by influencing electron transport pathways.

- Biomedical Applications: Spherical particles between 10–50 nm generally ensure good dispersion in biological fluids and reduce aggregation, improving circulation and imaging contrast.

- Nanoelectronics: Uniform size distribution and controlled morphology help maintain consistent electrical properties, making spherical or slightly elongated shapes preferred.

- Antibacterial Coatings: Surface roughness and particle shape can affect bacterial adhesion; moderately sized spherical or irregular shapes might improve antimicrobial efficiency.

Additionally, practical factors such as synthesis scalability, stability against oxidation, and ease of functionalization should guide the choice. Collaborating with suppliers offering tailored nanoparticle features can streamline achieving the right balance.

Request a custom quote for high-quality bismuth spherical powder.

Other Spherical Nanoparticles Requiring Size and Morphology Analysis

In addition to bismuth nanoparticles, many other spherical nanopowders demand precise size and morphology characterization to ensure optimal performance in their respective applications. The size and shape of these particles directly influence their physical, chemical, and functional properties, making thorough analysis essential for quality control and research development.

Some of the most commonly analyzed spherical nanoparticles include:

| Nanoparticle Type | Typical Applications | Why Size and Morphology Matter |

| Silver (Ag) Nanoparticles | Biomedical imaging, drug delivery, and catalysis | Particle size affects antimicrobial efficiency and electrical conductivity. Morphology influences dispersion and surface interaction. |

| Gold (Au) Nanoparticles | Biomedical imaging, drug delivery, catalysis | Size controls optical properties (plasmonics), while shape affects cellular uptake and catalytic activity. |

| Silicon Nanoparticles | Drug carriers, fillers in composites, chromatography | Uniform size ensures consistent flow and release; morphology impacts packing density and surface chemistry. |

| Titanium Nanoparticles | Photocatalysis, UV protection, pigments | Size influences light absorption and reactivity; morphology affects surface area and aggregation tendency. |

| Iron Nanoparticles | Magnetic resonance imaging (MRI), drug targeting | Particle size determines magnetic properties; shape affects biodistribution and targeting efficiency. |

Proper characterization of size distribution, aspect ratio, and surface texture for these spherical nanoparticles ensures their tailored performance across diverse industries such as electronics, medicine, environmental technology, and energy. Integrating advanced techniques like TEM, SEM, and DLS in routine analysis helps manufacturers and researchers maintain high-quality standards and meet application-specific requirements.

FAQ

| Question | Answer |

| What’s the most accurate technique for size analysis? | TEM provides the highest resolution, but DLS and XRD offer faster, approximate sizing. |

| Are bismuth nanoparticles always spherical? | No, synthesis conditions can produce rods, plates, flakes, or agglomerates. |

| Can TEM fully replace XRD for size reporting? | No, TEM shows particle size; XRD provides crystallite domain size, complementing each other. |

| How can agglomeration be reduced in powder samples? | Sonication in solvents like ethanol or adding dispersants prior to measurement helps. |

Conclusion

Understanding and precisely controlling the size and morphology of bismuth nanoparticles is essential to unlocking their full potential in thermoelectric, catalytic, biomedical, and electronic applications. Utilizing a combination of advanced characterization techniques and standardized reporting practices enables consistent quality and performance optimization. Heeger Materials offers high-quality, custom-controlled bismuth nanopowders with comprehensive analysis and technical support tailored to your industry’s needs.

Looking for high-quality bismuth spherical powder? Contact us today!