Die Wahl des richtigen Stickstoff-Atomisierten Edelstahlpulvers für die moderne Fertigung

Stickstoffzerstäubte Edelstahlpulver sind in fortschrittlichen Fertigungsverfahren unverzichtbar geworden, vom Metall-Spritzguss (MIM) über die additive Fertigung (AM) bis hin zu hochpräzisen Keramik-Metall-Hybridteilen. Ihre Leistung beeinflusst direkt die Dichte, Korrosionsbeständigkeit, mechanische Festigkeit und Maßgenauigkeit. Da die moderne Industrie immer anspruchsvollere Mikrostrukturen und eine höhere Produktionszuverlässigkeit anstrebt, ist die Auswahl des richtigen Pulvertyps nicht mehr optional, sondern eine zentrale technische Entscheidung.

Dieser Artikel bietet einen umfassenden, wissenschaftlich fundierten Leitfaden für die Auswahl des richtigen stickstoffzerstäubten Edelstahlpulvers, in dem Prozessgrundlagen, Leistungsdaten, Edelstahlsorten, Anwendungslogik und Auswahlrahmen untersucht werden. Alle Abschnitte enthalten strukturierte Tabellen und Listen, die eine klare, umsetzbare Entscheidungsfindung unterstützen.

Unter Erweiterte PulvertechnologieWir haben uns auf hochwertige Pulverprodukte spezialisiert, die eine optimale Leistung für industrielle und wissenschaftliche Anwendungen gewährleisten.

Wodurch unterscheidet sich Stickstoff-atomisiertes Edelstahlpulver von anderen Pulvern?

Stickstoff-atomisierte Edelstahlpulver unterscheiden sich deutlich von wasser-atomisierten oder mechanisch hergestellten Pulvern. Die kontrollierte inerte Atmosphäre, die verfeinerten Erstarrungsmechanismen und die durch Stickstoff unterstützte Legierungsverfestigung bieten hervorragende Eigenschaften für die Präzisionsfertigung. Bevor man sich mit der Sortenauswahl befasst, ist es wichtig, die zugrunde liegende metallurgische Logik zu verstehen.

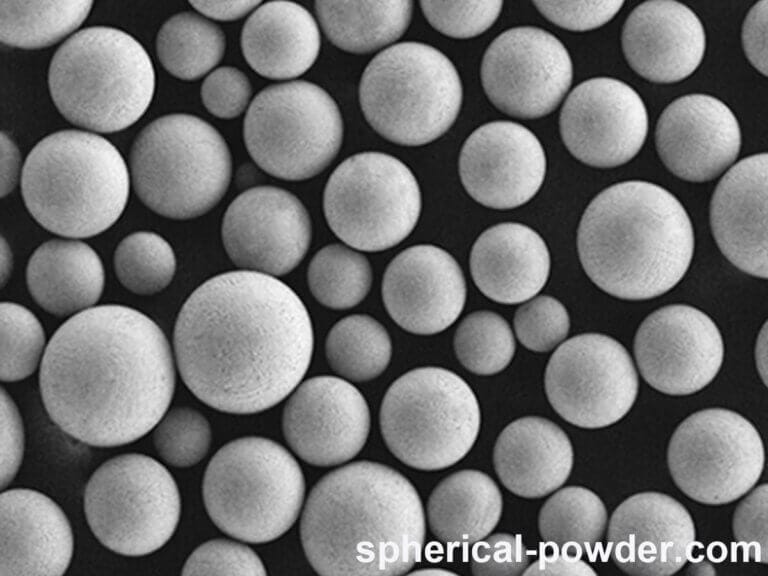

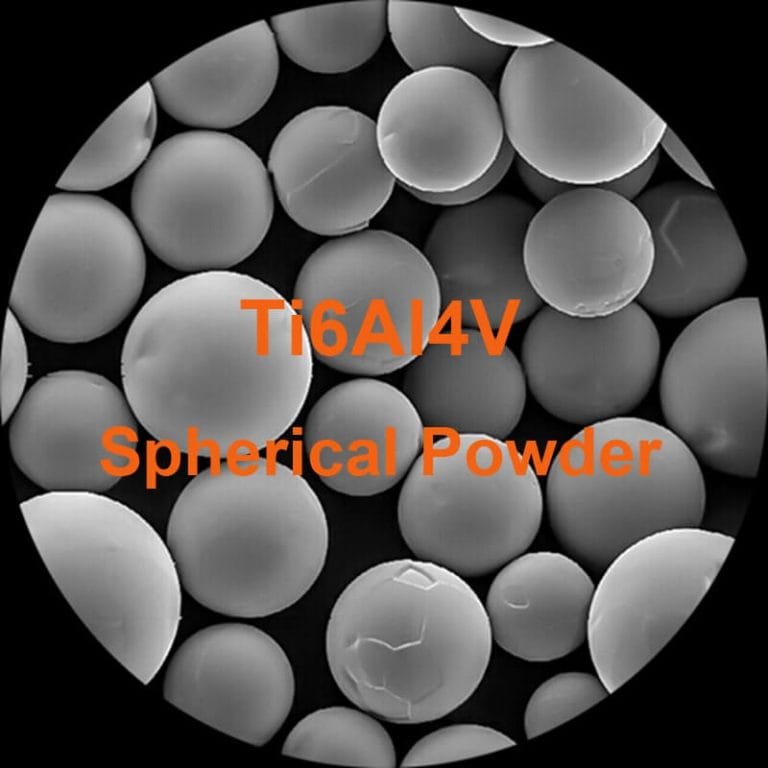

Diese Pulver werden häufig in der additiven Fertigung und bei der Herstellung von Keramik-Metall-Verbundwerkstoffen verwendet, da die kugelförmige Form die Fließfähigkeit verbessert und der geringe Sauerstoffgehalt Sprödigkeit verhindert. In der nachstehenden Tabelle sind die wichtigsten Unterschiede zwischen stickstoffzerstäubten Pulvern und herkömmlichen Pulvern zusammengefasst.

| Pulver Typ | Form | Sauerstoffgehalt | Fließfähigkeit | Geeignete Verfahren |

| Stickstoff-Atomisiertes Edelstahl-Pulver | Sphärisch (95%+) | Niedrig (≤500 ppm) | Ausgezeichnet | AM, MIM, Heißpressen |

| Wasser-Atomisiertes Pulver | Unregelmäßig | Hoch (1000-3000 ppm) | Schlecht-Mäßig | Presse & Sinter |

| Mechanisch / Mahlen Pulver | Flockig oder kantig | Sehr hoch | Schlecht | Begrenzte industrielle Nutzung |

Stickstoffzerstäubte Edelstahlpulver übertreffen alternative Pulverquellen in fast allen Strukturmerkmalen. Ihre kugelförmige Morphologie gewährleistet eine gleichmäßige Packungsdichte und minimiert Defekte beim Sintern oder Laserschmelzen, was für die Herstellung von Keramik-Metall-Hybriden unerlässlich ist.

Entdecken Sie unser hochwertiges kugelförmiges Pulver aus Edelstahllegierung Produkte.

Was sind die wichtigsten Eigenschaften, die bei der Auswahl von Edelstahlpulver zu berücksichtigen sind?

Die Auswahl von Edelstahlpulver erfordert eine Bewertung der strukturellen, chemischen und verarbeitungsbezogenen Eigenschaften. Jeder Parameter wirkt sich direkt auf die Dichte des Pulverbettes, das Sinterverhalten und die mechanische Leistung des Endprodukts aus.

Im Folgenden finden Sie eine detaillierte Liste der wichtigsten Bewertungsmetriken, die bei der Entwicklung von Keramik-Metall-Verbundwerkstoffen und der Optimierung von AM eingesetzt werden.

- Partikelgrößenverteilung (PSD): Eine D50 zwischen 15-53 μm ist optimal für LPBF; 7-15 μm funktioniert am besten für MIM.

- Fließfähigkeit: Die Hall-Fließgeschwindigkeit ≤18 s/50 g gewährleistet eine stabile Verteilung und gleichmäßige Schichtdichte.

- Sauerstoffgehalt: In der Regel ≤500 ppm; bei Pulvern für medizinische Zwecke sind ≤100 ppm erforderlich.

- Sphärizität: ≥95% gewährleistet gleichmäßiges Schmelzen und minimiert die Porosität.

- Reinheit und Einschlussgrad: Nichtmetallische Einschlüsse müssen unter 0,01% gehalten werden, um Sprödigkeit zu vermeiden.

Diese Faktoren bestimmen direkt, ob ein Pulver dichte, fehlerfreie Strukturen erzeugt. Für die integrierte Keramik-Metall-Fertigung sind eine hohe Sphärizität und eine geringe Oxidation besonders wichtig, um eine Delaminierung der Grenzflächen während der Temperaturwechsel zu verhindern.

Wie verbessern Stickstoff-atomisierte Edelstahlpulver die Fertigungsprozesse?

Das Verständnis der verfahrensspezifischen Vorteile trägt dazu bei, warum diese Pulver für die industrielle und keramikbezogene Fertigung bevorzugt werden.

Die thermische Stabilität und die kontrollierte Stickstoffverfestigung tragen zu einer vorhersehbaren Schrumpfung, überlegener mechanischer Integrität und glatteren Oberflächen bei.

Prozessvorteile von Stickstoff-atomierten Edelstahlpulvern

| Vorteil Kategorie | Beschreibung |

| Optimierung der Fließfähigkeit | Die kugelförmige Form erhöht die Dichte und Gleichmäßigkeit des Pulverbettes. |

| Niedrige Sauerstoffwerte | Minimiert die Bildung von Oxideinschlüssen; ideal für AM- und Keramikbindungen. |

| Stickstoffverstärkung | Die Mischkristallverfestigung verbessert Härte und Verschleißfestigkeit. |

| Verbesserte Abkühlungsraten | Das feine Gefüge verbessert die mechanische Stabilität nach dem Sintern. |

Diese kombinierten Vorteile reduzieren Maßabweichungen, verbessern die Leistung der Teile und minimieren Defekte - entscheidende Faktoren bei der Arbeit mit keramikgestützten Strukturen oder hybriden Baugruppen, die hohe Präzision erfordern.

Welche Edelstahlpulversorten sind am gebräuchlichsten, und wie sehen sie im Vergleich aus?

Verschiedene Edelstahlsorten bieten unterschiedliche Korrosionsbeständigkeit, magnetisches Verhalten und mechanische Eigenschaften. Stickstoff-atomisierte Versionen dieser Sorten bieten verbesserte Reinheit und Mikrostrukturkontrolle.

Die folgende Tabelle gibt einen Überblick über die in der modernen Fertigung am häufigsten verwendeten Edelstahlpulversorten.

Vergleich der wichtigsten Edelstahlpulversorten

| Klasse | Schlüssel Chemie | Stärke | Korrosionsbeständigkeit | Typische Anwendungsfälle |

| 304L | Cr-Ni, kohlenstoffarm | Mäßig | Gut | Allgemeine AM, MIM, Keramik-Metall-Gerüste |

| 316L | Cr-Ni-Mo | Hoch | Ausgezeichnet (Chloride) | Medizinische, marine und chemische Ausrüstung |

| 400er-Serie (430, 410) | Ferritisch / Martensitisch | Mäßig-hoch | Messe | Magnetische Anwendungen, Autoteile |

| 17-4PH | Cr-Ni-Cu (PH) | Sehr hoch | Gut | Luft- und Raumfahrt, hochfeste Komponenten |

304L bietet ein ausgewogenes Verhältnis von Leistung und Kosten, während 316L in hochkorrosiven Umgebungen dominiert. 17-4PH bietet eine überragende Festigkeit für anspruchsvolle Anwendungen, die Dimensionsstabilität und Belastbarkeit erfordern.

Warum ist Stickstoff-atomisiertes Edelstahlpulver 304L in der Fertigung so beliebt?

304L gehört aufgrund seiner ausgewogenen Korrosionsbeständigkeit, seiner moderaten Kosten und seiner breiten Verarbeitungskompatibilität zu den am häufigsten verwendeten rostfreien Stahlpulvern.

Die folgende Liste zeigt, warum sich die Industrie für stickstoffverdüstes 304L entscheidet.

Die wichtigsten Vorteile von Stickstoff-atomiertem 304L-Pulver

- Hoher Reinheitsgrad in Verbindung mit niedrigem Kohlenstoffgehalt verbessert die Schweißbarkeit.

- Sphärische Partikel verbessern die Streuung bei LPBF und die Vermischung des Bindemittels bei MIM.

- Die Korrosionsbeständigkeit bleibt in neutralen Umgebungen stabil.

- Kostengünstige Option für allgemeine Strukturbauteile und keramische Hybridteile.

Industrien, die mit Keramik-Metall-Baugruppen arbeiten, wie z. B. Sensoren, Vorrichtungen und Präzisionshalterungen, bevorzugen 304L, weil es eine vorhersehbare Schrumpfung während des Sinterns bietet und so die Belastung der Verbindung reduziert.

Warum 316L-Stickstoffatomiertes Edelstahlpulver für raue Umgebungen wählen?

316L wurde speziell für korrosive oder chloridreiche Bedingungen entwickelt und wird häufig für medizinische Geräte und Schiffsausrüstung verwendet.

Nachstehend finden Sie eine Tabelle mit einer Zusammenfassung der verbesserten Leistungsmerkmale.

Die wichtigsten Leistungsmerkmale von stickstoffatomiertem 316L

| Eigentum | Wert/Verhalten |

| Mo Inhalt | 2-3% für hervorragende Lochfraßbeständigkeit |

| Sauerstoffgehalt | ≤100 ppm (medizinische Qualität) |

| Zugfestigkeit (SLM) | ~580 MPa |

| Dehnung | ~35% |

316L eignet sich hervorragend für keramikbezogene Prozesse, da sein niedriger Oxidgehalt und seine duktile Struktur die thermische Rissbildung beim Verbinden von Keramik und Metall minimieren.

Welche Rolle spielen Pulver aus rostfreiem Stahl der Serie 400 in der modernen Technik?

Ferritische und martensitische nichtrostende Stähle der 400er-Serie bieten magnetische Eigenschaften und niedrigere Kosten als austenitische Sorten.

In der folgenden Liste sind typische Anwendungen und Einschränkungen aufgeführt.

Merkmale von Edelstahlpulver der Serie 400

- Die natürliche magnetische Reaktion unterstützt Sensoren und magnetische Halterungen.

- Ein geringerer Nickelgehalt senkt die Gesamtmaterialkosten.

- Geeignet für trockene, korrosionsarme Umgebungen.

- Für Verschleißanwendungen sind Optionen mit höherer Härte erhältlich.

Pulver der Serie 400 werden üblicherweise dort eingesetzt, wo das magnetische Verhalten wichtig ist. Bei der Herstellung von Keramik-Metall-Hybridstrukturen, die Feuchtigkeit ausgesetzt sind, müssen ihre Einschränkungen in chloridhaltigen Umgebungen berücksichtigt werden.

Warum ist 17-4PH Stickstoff-atomisiertes Edelstahlpulver für hochfeste Bauteile unerlässlich?

17-4PH ist ein ausscheidungshärtender rostfreier Stahl, der häufig in der Luft- und Raumfahrt, in Präzisionsmaschinen und in tragenden Strukturen verwendet wird.

Die nachstehende Tabelle gibt einen Überblick über die mechanischen Eigenschaften je nach Wärmebehandlungszustand.

Mechanische Eigenschaften von 17-4PH unter verschiedenen Bedingungen

| Bedingung für die Wärmebehandlung | Zugfestigkeit | Härte | Anmerkungen |

| Geglüht | ~600 MPa | ~250 HV | Geringere Festigkeit; leichtere Bearbeitung |

| H900 | ~1300 MPa | ~40-44 HRC | Maximale Stärke |

| H1150 | ~930 MPa | ~28-32 HRC | Ausgewogene Korrosionsbeständigkeit |

Durch die Stickstoffzerstäubung erreicht 17-4PH eine höhere Dichte und ein saubereres Mikrogefüge, wodurch es sich für keramikgestützte Aktuatoren, strukturelle Rahmen und moderne technische Werkzeuge eignet.

Wie können Hersteller das richtige mit Stickstoff aromatisierte Edelstahlpulver auswählen?

Ein strukturierter Auswahlrahmen gewährleistet eine vorhersehbare Leistung und ein optimales Kostenmanagement.

Die nachstehende Liste enthält eine empfohlene vierstufige Methode zur Auswahl der Technik.

Vierstufiges Verfahren zur Auswahl von Edelstahlpulver

- Definieren Sie die Einsatzbedingungen: Temperatur, Korrosion, mechanische Belastung, magnetische Anforderungen.

- Passen Sie die Pulversorte den funktionalen Anforderungen an: 316L für Chloride, 17-4PH für Festigkeit, 304L für allgemeine Anwendungen.

- Überprüfen Sie die Pulverspezifikationen: Sphärizität, PSD, Durchflussrate und Sauerstoffgehalt.

- Bewerten Sie die Kompatibilität der Produktionsverfahren: AM, MIM, Laserauftragsschweißen oder Heißpressen.

Durch diese Schritte wird sichergestellt, dass das ausgewählte Edelstahlpulver sowohl den technischen Anforderungen als auch den langfristigen Zuverlässigkeitszielen für die integrierte Keramik-Metall-Fertigung entspricht.

FAQ

| Frage | Antwort |

| Ist mit Stickstoff zerstäubtes Pulver besser für AM? | Ja - seine Kugelförmigkeit und geringe Oxidation minimieren Defekte. |

| Kann sich Edelstahlpulver gut mit Keramik verbinden? | Ja, insbesondere sauerstoffarme Sorten, die die Rissbildung an den Grenzflächen verringern. |

| Beeinflusst der Sauerstoffgehalt des Pulvers die Festigkeit? | Hoher Sauerstoffgehalt erhöht die Sprödigkeit, niedriger Sauerstoffgehalt verbessert die Duktilität. |

| Sind die Pulver der Serie 400 korrosionsbeständig? | Mäßig - besser für trockene Umgebungen. |

| Welche Sorte eignet sich am besten für den Einsatz in aggressiven Chemikalien? | 316L aufgrund der durch Mo verbesserten Lochfraßbeständigkeit. |

Schlussfolgerung

Stickstoff-atomisierte Edelstahlpulver bieten eine wissenschaftliche Kombination aus Reinheit, Sphärizität, mechanischer Stabilität und mikrostruktureller Verfeinerung, die mit herkömmlichen Pulvern nicht erreicht werden kann. Wenn man versteht, wie sich die verschiedenen Sorten - 304L, 316L, 400er und 17-4PH - in verschiedenen Umgebungen und Prozessen verhalten, können Hersteller die Integrität ihrer Teile optimieren, Fehler reduzieren und eine höhere Produktionszuverlässigkeit erreichen.

Für die keramikverwandte Fertigung, bei der thermische Kompatibilität und Grenzflächenstabilität von entscheidender Bedeutung sind, liefern stickstoffzerstäubte Pulver die für technische Anwendungen der nächsten Generation erforderliche Konsistenz. Durch die Anwendung des strukturierten Auswahlrahmens können Ingenieure und Hersteller vertrauensvoll die Edelstahlpulversorte auswählen, die den Leistungsanforderungen und langfristigen Produktzielen wirklich entspricht.

Sie suchen ein hochwertiges Pulverprodukt? Kontaktieren Sie uns noch heute!