Polvo de aleación de níquel 2025: Propiedades, aplicaciones y perspectivas de mercado

Visión general

Polvo de aleación de níquel es un material de alto rendimiento conocido por su excelente resistencia a la corrosión y a las altas temperaturas y excelentes propiedades mecánicas. Estas aleaciones se utilizan ampliamente en aeroespacial, energética, automovilística, médica y de fabricación aditiva (impresión 3D) debido a su capacidad para resistir entornos extremos, como calor, presión y corrosión elevados.

Aleaciones a base de níquel, como Inconel, Monel, Hastelloy y NiCrdesempeñan un papel crucial en superaleaciones, revestimientos, componentes de alta resistencia y tecnologías avanzadas de fabricación. Su alta durabilidad y estabilidad química los hacen indispensables para aplicaciones críticas.

En Heeger Materials Inc.Estamos especializados en polvos de aleación de níquel de gran purezagarantizando rendimiento óptimo para aplicaciones industriales y científicas.

¿Por qué elegir aleación de níquel en polvo?

Los polvos de aleación de níquel ofrecen resistencia excepcional a condiciones extremaspor lo que son ideales para aplicaciones aeroespaciales, energéticas y de procesamiento químico.

Principales ventajas

- Resistencia superior a la corrosión y la oxidación - Ideal para entornos marinos, químicos y de altas temperaturas.

- Resistencia a altas temperaturas - Mantiene las propiedades mecánicas bajo calor extremopor lo que es perfecto para aplicaciones aeroespaciales y energéticas.

- Excelente rendimiento mecánico - Proporciona alta resistencia a la tracción, resistencia a la fluencia y durabilidad.

- Biocompatibilidad y resistencia al desgaste - Utilizado en implantes médicos y componentes industriales sometidos a grandes esfuerzos.

- Optimizado para la fabricación aditiva - Muy utilizado en Impresión 3D para geometrías complejas y piezas de alto rendimiento.

En busca de ¿polvo de aleación de níquel de alta calidad? Explore la selección de Heeger Materials.

Productos relacionados

-

Alúmina en polvo esférico - Al2O3 en polvo - Fabricación aditiva - Impresión 3D

-

Polvo esférico de nitruro de aluminio - Polvo AlN - Fabricación aditiva - Impresión 3D

-

Polvo esférico de carburo de boro - Polvo B4C - Fabricación aditiva - Impresión 3D

-

Polvo esférico de nitruro de boro - Polvo de BN - Fabricación aditiva - Impresión 3D

Las mejores calidades de polvo de aleación de níquel para distintas aplicaciones

Los polvos de aleación de níquel se clasifican en función de composición, propiedades mecánicas y aplicaciones previstas.

Comparación

| Composición de la aleación | Propiedades clave | Mejores aplicaciones |

|---|---|---|

| Inconel 625 (Ni-Cr-Mo) | Excelente resistencia a la corrosión, alta resistencia | Industria aeroespacial, naval y química |

| Inconel 718 (Ni-Cr-Fe-Nb-Mo) | Resistencia a altas temperaturas y a la oxidación | Motores a reacción, turbinas de gas, centrales eléctricas |

| Hastelloy C-22 (Ni-Cr-Mo-W) | Resistencia extrema a la corrosión | Procesamiento químico, marina, reactores nucleares |

| Monel 400 (aleación Ni-Cu) | Alta resistencia a la corrosión, buena resistencia mecánica | Marina, petróleo y gas, industria química |

| Aleación NiCr (Níquel-Cromo) | Alta estabilidad térmica, resistencia a la oxidación | Revestimientos de proyección térmica, elementos calefactores |

Aleaciones Inconel domina aplicaciones aeroespaciales y energéticasmientras que Hastelloy es esencial para el procesamiento químico.

Solicite un presupuesto personalizado para aleaciones de níquel en polvo.

Aplicaciones en la industria

Los polvos de aleación de níquel se utilizan en aplicaciones de alto rendimiento que requieren durabilidad, resistencia a la corrosión y resistencia al calor superiores.

Aplicaciones industriales clave

| Industria | Aplicación | Ventajas |

|---|---|---|

| Aeroespacial y defensa | Motores a reacción, álabes de turbina, sistemas de escape | Resistencia a altas temperaturas, estabilidad a la oxidación |

| Energía y generación de electricidad | Turbinas de gas, reactores nucleares, pilas de combustible | Estabilidad térmica, resistencia a la corrosión |

| Automoción y transporte | Turbocompresores, sistemas de escape, componentes del motor | Resistencia al desgaste, alta resistencia |

| Medicina y sanidad | Implantes quirúrgicos, prótesis y dispositivos dentales | Biocompatibilidad, resistencia a la corrosión |

| Fabricación aditiva (AM) | Piezas industriales y médicas impresas en 3D | Alta precisión, geometrías complejas |

Con el creciente demanda de materiales de alto rendimiento, polvos de aleación de níquel se están convirtiendo en esenciales en industrias críticas.

Descubra nuestros polvos de aleación de níquel de gran pureza.

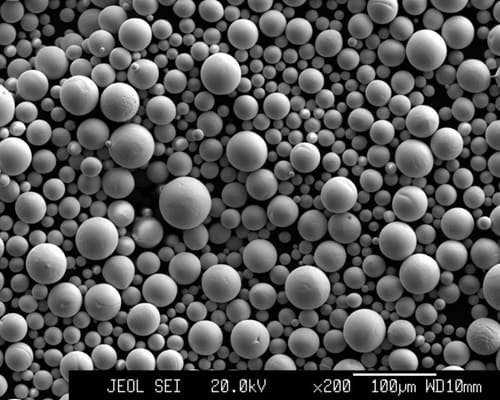

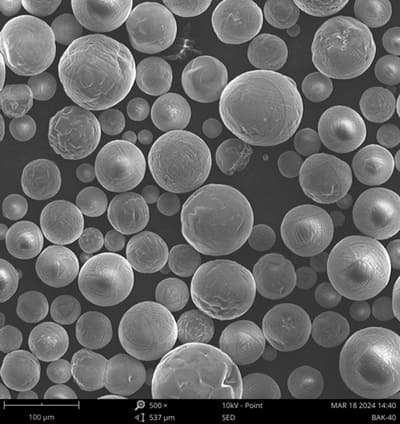

Tamaño y forma de las partículas

En distribución del tamaño de las partículas (PSD) y morfología impacto fluidez, comportamiento de sinterización y calidad del producto final en Impresión 3D, revestimientos y aplicaciones estructurales.

Tamaño óptimo de las partículas

| Gama de tamaños de partículas | Mejor aplicación |

|---|---|

| 0,5-10 µm | Recubrimientos de alto rendimiento, aplicaciones catalizadoras |

| 10-45 µm | Implantes biomédicos, revestimientos resistentes al desgaste |

| 45-150 µm | Impresión 3D, componentes aeroespaciales |

Polvo de aleación de níquel esférico frente a irregular: ¿cuál es mejor?

| Forma de polvo | Características | Mejor aplicación |

|---|---|---|

| Esférica | Alta fluidez, empaquetado uniforme, sinterización mejorada | Impresión 3D, aeroespacial, aplicaciones médicas |

| Irregular | Mayor superficie, mayor porosidad | Revestimientos resistentes al desgaste, tratamiento químico |

Polvos esféricos de aleación de níquel se prefieren para fabricación aditivamientras que polvos irregulares se utilizan en revestimientos y procesos químicos.

Explore nuestros polvos de aleación de níquel optimizados.

Normas de calidad

Para garantizar rendimiento y fiabilidad constantesLos polvos de aleación de níquel deben cumplir estrictas normas internacionales que rigen su pureza, composición, distribución granulométrica y propiedades mecánicas. Estas normas son cruciales para aplicaciones aeroespaciales, médicas, energéticas y de fabricación aditiva.

Principales normas de calidad

| Estándar | Descripción |

|---|---|

| ASTM B637 | Especificación para superaleaciones a base de níquel utilizadas en aplicaciones aeroespaciales y de alta temperatura. |

| ASTM F3055 | Norma para polvos de aleación de níquel utilizados en la fabricación aditiva (impresión 3D). |

| ISO 15156 | Norma internacional para aleaciones de níquel utilizadas en aplicaciones resistentes a la corrosión. |

| AMS 5662 | Especificación de materiales aeroespaciales para Aleación Inconel 718. |

| Conformidad con RoHS y REACH | Garantiza seguridad medioambiental y restricción de sustancias peligrosas. |

¿Por qué elegir polvo de aleación de níquel certificado?

- Garantiza una gran pureza y rendimiento - Garantías resistencia mecánica y a la corrosión.

- Esencial para uso aeroespacial y médico - Reuniones estrictas normas industriales para entornos de alto rendimiento.

- Optimizado para la fabricación aditiva - Garantiza fluidez e imprimibilidad constantes.

- Cumplimiento global - Se adhiere a normas internacionales para aplicaciones de materiales avanzados.

En Heeger Materials Inc.ofrecemos polvos de aleación de níquel de gran pureza que cumplan Normas ASTM, ISO y AMSgarantizando calidad y fiabilidad excepcionales.

Análisis de costes

El precio de aleación de níquel en polvo depende de varios factores, entre ellos coste de la materia prima, método de producción, tamaño de las partículas y demanda del mercado. Dado que el níquel es un material estratégicosu precio se ve influido por fluctuaciones de la cadena de suministro y demanda industrial.

Factores que afectan al coste del polvo de aleación de níquel

- Composición elemental - Las aleaciones con molibdeno, cromo y wolframio suelen ser más caras..

- Método de producción - La atomización con gas y la atomización con plasma aumentan el coste en comparación con el fresado mecánico.

- Distribución del tamaño de las partículas (PSD) - Los tamaños de partícula más pequeños (5-50 µm) para aplicaciones médicas y de impresión 3D requieren un procesamiento avanzado, lo que eleva los costes..

- Demanda del mercado y cadena de suministro - Los precios fluctúan debido a necesidades de los sectores aeroespacial, energético y manufacturero.

Comparación de precios

| Tipo de aleación de níquel | Coste ($/kg) | Caso de uso común |

|---|---|---|

| Inconel 625 (aleación de níquel de alto rendimiento) | 400-400 - 400-1,500 | Industria aeroespacial, naval y química |

| Inconel 718 (aleación de níquel de calidad aeroespacial) | 800-800 - 800-2,500 | Motores a reacción, turbinas de gas, centrales eléctricas |

| Hastelloy C-22 (aleación de níquel resistente a la corrosión) | 700-700 - 700-2,000 | Procesamiento químico, marina, reactores nucleares |

| Monel 400 (aleación de níquel para uso marino) | 500-500 - 500-1,800 | Marina, petróleo y gas, industria química |

| Aleación NiCr (aleación de níquel de alta temperatura) | 600-600 - 600-2,200 | Revestimientos de proyección térmica, elementos calefactores |

Inconel 718 se utiliza ampliamente en aeroespacialmientras que Se prefiere el Hastelloy C-22 por su extrema resistencia a la corrosión.

Solicite un presupuesto de precios al por mayor de aleaciones de níquel en polvo.

Métodos de producción

Diferentes técnicas de producción de polvo impacto morfología, pureza y coste de las partículaspor lo que es esencial seleccionar el método adecuado para la aplicación prevista.

Comparación

| Método de producción | Forma de las partículas | Pureza | Coste | El mejor caso de uso |

|---|---|---|---|---|

| Fresado mecánico | Irregular | Moderado | $$ | Recubrimientos resistentes al desgaste, aplicaciones de sinterización |

| Atomización de gas (GA) | Esférica | Alta | $$$ | Impresión 3D, piezas aeroespaciales |

| Atomización por plasma (PA) | Altamente esférico | Ultra Alta | $$$$ | Aplicaciones médicas, AM de alta precisión |

| Fusión por inducción en vacío (VIM) | Dendrítico o esférico | Muy alta | $$$ | Superaleaciones, aplicaciones aeroespaciales |

Polvos de aleaciones de níquel atomizados con gas y tratados con plasma se prefieren para aplicaciones de alto rendimientogarantizando fluidez e imprimibilidad superiores.

Heeger Materials Inc. se especializa en polvos de aleación de níquel de gran pureza atomizados por gas para aplicaciones industriales de vanguardia.

PREGUNTAS FRECUENTES

| Pregunta | Respuesta |

|---|---|

| ¿Para qué se utiliza el polvo de aleación de níquel? | Se utiliza en componentes aeroespaciales, turbinas de gas, implantes médicos, revestimientos e impresión 3D. |

| ¿Por qué se utilizan aleaciones de níquel en aplicaciones aeroespaciales? | Las aleaciones de níquel proporcionan resistencia a altas temperaturas, resistencia a la oxidación y resistencia mecánicapor lo que son ideales para motores a reacción y componentes de turbina. |

| ¿Qué aleación de níquel es mejor para resistir la corrosión? | Hastelloy C-22 y Monel 400 oferta resistencia excepcional a productos químicos agresivos y entornos marinos. |

| ¿En qué se diferencia una aleación de níquel del acero inoxidable? | Las aleaciones de níquel son más resistentes a la corrosión, más fuertes y tienen mayor estabilidad térmica que el acero inoxidable.. |

| ¿Dónde puedo comprar polvo de aleación de níquel de gran pureza? | Heeger Materials Inc. proporciona aleaciones de níquel en polvo para aplicaciones industriales. |

Conclusión

Polvo de aleación de níquel es un material crítico para las industrias de alta tecnología, ofreciendo excepcional resistencia al desgaste, estabilidad a altas temperaturas y resistencia a la corrosión para aplicaciones aeroespaciales, médicas, energéticas y de fabricación aditiva.

Para polvos de aleación de níquel de alta calidad, Heeger Materials Inc. proporciona soluciones a medida con polvos esféricos atomizados por gas de gran pureza.

¿Busca polvo de aleación de níquel de primera calidad? Póngase en contacto con nosotros

.jpg)