High-Entropy Alloy Powder 2025: Properties, Applications, and Market Insights

Overview of High-Entropy Alloy Powder

High-entropy alloy (HEA) powder is a cutting-edge material composed of multiple principal elements in nearly equal atomic ratios, which results in exceptional mechanical strength, thermal stability, and corrosion resistance. Unlike traditional alloys, which rely on a single dominant element, HEAs leverage the synergy of multiple metals to achieve superior properties.

Due to their high hardness, excellent oxidation resistance, and outstanding wear resistance, high-entropy alloy powders are extensively used in aerospace, defense, biomedical, energy, and additive manufacturing (3D printing).

At Heeger Materials Inc., we provide high-purity, gas-atomized high-entropy alloy powders, ensuring optimal performance for advanced industrial applications.

Why Choose High-Entropy Alloy Powder?

High-entropy alloys are revolutionizing materials science by offering unmatched strength, stability, and versatility for extreme applications.

Key Benefits of High-Entropy Alloy Powder

- Superior Mechanical Strength – HEAs exhibit high hardness, wear resistance, and toughness, outperforming conventional alloys.

- Excellent Thermal Stability – Maintains structural integrity at extreme temperatures, making it ideal for aerospace and energy applications.

- Exceptional Corrosion & Oxidation Resistance – Suitable for harsh environments, including marine and chemical industries.

- Tailorable Composition – Allows customization of properties based on application needs.

- Enhanced Performance for Additive Manufacturing – HEAs are widely used in 3D printing and advanced manufacturing technologies.

Looking for high-performance HEA powder? Explore Heeger Materials’ selection.

Best High-Entropy Alloy Powder Compositions for Different Applications

HEA powders are classified based on elemental composition, application, and processing method.

Comparison of Common High-Entropy Alloy Powders

| Alloy Composition | Key Properties | Best Applications |

|---|---|---|

| CoCrFeNiMn | High strength, corrosion resistance | Aerospace, marine, biomedical |

| AlCoCrFeNi | High-temperature stability, oxidation resistance | Turbine blades, heat exchangers |

| MoNbTaW | Ultra-high temperature resistance, hardness | Aerospace, nuclear reactors |

| TiVZrNbHf | Lightweight, high ductility, biocompatibility | Medical implants, structural materials |

| NiCrCoFeMo | Wear resistance, excellent mechanical strength | Cutting tools, coatings |

MoNbTaW HEAs are preferred for high-temperature applications, while TiVZrNbHf HEAs are widely used in biomedical and structural applications.

Request a custom quote for HEA powders.

Related Products

-

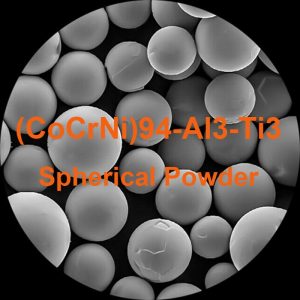

(CoCrNi)94-Al3-Ti3 High-entropy Alloy Spherical Powder – (CoCrNi)94-Al3-Ti3 HEA – Additive Manufacturing – 3D Printing

-

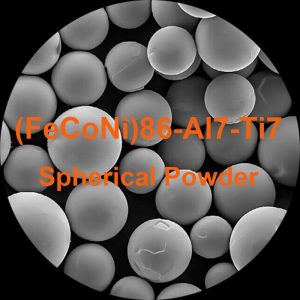

(FeCoNi)86-Al7-Ti7 High-entropy Alloy Spherical Powder – (FeCoNi)86-Al7-Ti7 HEA – Additive Manufacturing – 3D Printing

-

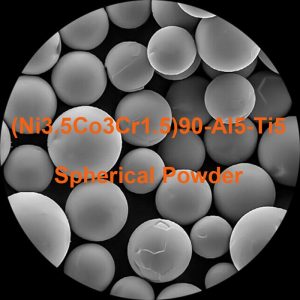

(Ni3.5Co3Cr1.5)90-Al5-Ti5 High-entropy Alloy Spherical Powder – (Ni3.5Co3Cr1.5)90-Al5-Ti5 HEA – Additive Manufacturing – 3D Printing

-

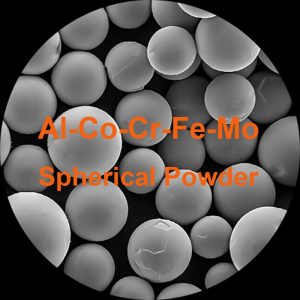

Al-Co-Cr-Fe-Mo High-entropy Alloy Spherical Powder – Al-Co-Cr-Fe-Mo HEA – Additive Manufacturing – 3D Printing

Applications of High-Entropy Alloy Powder in Industry

HEA powders are used in high-performance applications that require extreme durability, thermal stability, and superior mechanical properties.

Key Industrial Applications of HEA Powder

| Industry | Application | Advantages |

|---|---|---|

| Aerospace & Defense | Jet engine components, heat shields | High strength-to-weight ratio, extreme temperature resistance |

| Biomedical & Healthcare | Surgical implants, prosthetics | Biocompatibility, corrosion resistance |

| Energy & Nuclear | Nuclear reactor components, fusion materials | Radiation resistance, thermal stability |

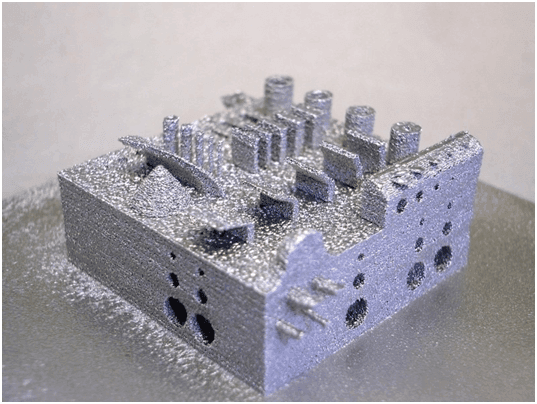

| Additive Manufacturing (AM) | 3D-printed high-performance parts | High precision, complex geometries |

| Wear-Resistant Coatings | Hard coatings, cutting tools | Superior hardness, extended lifespan |

With the growing demand for high-strength, corrosion-resistant materials, high-entropy alloy powders are rapidly becoming a game-changer in advanced industries.

Discover our high-purity HEA powders.

Particle Size and Shape in High-Entropy Alloy Powder

The particle size distribution (PSD) and morphology impact flowability, sintering behavior, and final product quality in 3D printing, coatings, and structural applications.

Optimal Particle Size for HEA Powder Applications

| Particle Size Range | Best Application |

|---|---|

| 0.5-10 µm | High-performance coatings, catalyst applications |

| 10-45 µm | Biomedical implants, advanced electronics |

| 45-150 µm | 3D printing, aerospace components |

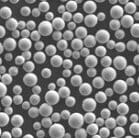

Spherical vs. Irregular High-Entropy Alloy Powder: Which is Better?

| Powder Shape | Characteristics | Best Application |

|---|---|---|

| Spherical | High flowability, uniform packing, improved sintering | 3D printing, aerospace, medical applications |

| Irregular | Higher surface area, increased porosity | Coatings, chemical processing, wear-resistant materials |

Spherical HEA powders are preferred for additive manufacturing, while irregular powders are used in coatings and chemical processes.

Explore our optimized HEA powders.

Quality Standards for High-Entropy Alloy Powder

To ensure reliability, consistency, and superior performance, high-entropy alloy (HEA) powders must meet strict international standards regulating their purity, composition, microstructure, and mechanical properties. These standards are critical for applications in aerospace, medical, defense, and additive manufacturing (AM).

Key Quality Standards for High-Entropy Alloy Powder

| Standard | Description |

|---|---|

| ASTM F3318 | Specification for metal powders, including HEAs, used in additive manufacturing. |

| ASTM B214 | Standard for particle size analysis of metal powders. |

| ISO 22068 | International standard for HEAs used in high-temperature applications. |

| AMS 4999 | Aerospace Material Specification for high-entropy alloys in turbine engines. |

| RoHS & REACH Compliance | Ensures environmental safety and restriction of hazardous substances. |

Why Choose Certified High-Entropy Alloy Powder?

- Ensures Optimal Purity & Performance – Guarantees high thermal stability and mechanical strength.

- Essential for Aerospace & Medical Use – Meets strict regulations for high-performance environments.

- Optimized for Additive Manufacturing – Ensures consistent powder flowability and printability.

- Global Compliance – Adheres to international standards for advanced material applications.

At Heeger Materials Inc., our high-purity HEA powders comply with ASTM, ISO, and AMS standards, ensuring outstanding quality and reliability.

Cost Analysis of High-Entropy Alloy Powder

The price of high-entropy alloy powder is influenced by various factors, including element composition, production method, particle size, and market demand. Since HEAs incorporate multiple high-performance metals, they are often more expensive than traditional alloys.

Factors Affecting High-Entropy Alloy Powder Cost

- Elemental Composition – HEAs containing rare elements like hafnium, rhenium, and tantalum are significantly more expensive.

- Production Method – Gas atomization and plasma atomization increase cost compared to mechanical milling.

- Particle Size Distribution (PSD) – Finer powders (5-50 µm) for 3D printing require advanced processing, raising costs.

- Market Demand & Industry Trends – Prices fluctuate due to increasing use in aerospace, energy, and biomedical industries.

Price Comparison of High-Entropy Alloy Powders

| High-Entropy Alloy Type | Cost ($/kg) | Common Use Case |

|---|---|---|

| CoCrFeNiMn HEA Powder | 200−200 – 200−800 | Aerospace, corrosion-resistant coatings |

| AlCoCrFeNi HEA Powder | 500−500 – 500−1,500 | Turbine blades, heat exchangers |

| MoNbTaW HEA Powder | 1,500−1,500 – 1,500−4,000 | Nuclear, extreme-temperature applications |

| TiVZrNbHf HEA Powder | 1,000−1,000 – 1,000−3,000 | Biomedical, structural materials |

| NiCrCoFeMo HEA Powder | 700−700 – 700−2,500 | Wear-resistant coatings, cutting tools |

MoNbTaW HEAs dominate high-temperature applications, while CoCrFeNiMn HEAs are widely used in marine and aerospace applications.

Request a bulk pricing quote for HEA powders.

Production Methods for High-Entropy Alloy Powder

Different powder production techniques impact particle morphology, purity, and cost, making it essential to select the right method for the intended application.

Comparison of High-Entropy Alloy Powder Production Methods

| Production Method | Particle Shape | Purity | Cost | Best Use Case |

|---|---|---|---|---|

| Mechanical Alloying (MA) | Irregular | Moderate | $$ | Wear-resistant coatings, sintering applications |

| Gas Atomization (GA) | Spherical | High | $$$ | 3D printing, aerospace parts |

| Plasma Atomization (PA) | Highly Spherical | Ultra-High | $$$$ | Medical applications, high-precision AM |

| Vacuum Induction Melting (VIM) | Dendritic or spherical | Very High | $$$ | Superalloys, aerospace applications |

Gas atomized and plasma-processed HEA powders are preferred for additive manufacturing and aerospace, ensuring superior flowability and printability.

Heeger Materials Inc. specializes in high-purity gas-atomized high-entropy alloy powders for cutting-edge industrial applications.

FAQ About High-Entropy Alloy Powder

| Question | Answer |

|---|---|

| What is high-entropy alloy powder used for? | HEAs are used in aerospace, energy, medical implants, coatings, and 3D printing. |

| Why are high-entropy alloys better than traditional alloys? | HEAs offer higher strength, better thermal stability, and superior corrosion resistance due to their multi-element composition. |

| Which HEA composition is best for aerospace applications? | AlCoCrFeNi and MoNbTaW HEAs provide high-temperature stability and oxidation resistance, making them ideal for jet engines and turbine blades. |

| How does HEA powder compare to titanium alloys? | HEAs can be stronger, more corrosion-resistant, and more thermally stable than titanium alloys, depending on composition. |

| Where can I buy high-purity HEA powder? | Heeger Materials Inc. provides premium HEA powders for industrial applications. |

Conclusion

High-entropy alloy powder is revolutionizing material science by offering superior mechanical strength, corrosion resistance, and thermal stability for aerospace, medical, energy, and additive manufacturing applications.

For top-quality HEA powders, Heeger Materials Inc. provides tailored solutions with high-purity, gas-atomized spherical powders.

Looking for premium high-entropy alloy powder? Contact us today!

.jpg)