How Do Silicon Nitride Powder and Granulated Powder Compare in Industrial Applications?

Silicon nitride has become one of the most important advanced ceramics due to its performance in high-temperature, wear-resistant, and structural applications. However, manufacturers often confuse Silicon Nitride Powder with Granulated Powder, even though these two materials serve fundamentally different roles in ceramic processing. Silicon nitride powder is a raw, unmodified ceramic precursor, whereas granulated powder is an engineered form designed explicitly for pressing-based shaping processes.

This article provides a scientific comparison of the two materials, exploring their definitions, properties, forming behavior, process compatibility, and performance impact on final sintered parts.

At Advanced Powder Tech, we specialize in high-quality silicon nitride powder products, ensuring optimal performance for industrial and scientific applications.

What Is Silicon Nitride Powder and How Is It Defined in Ceramic Processing?

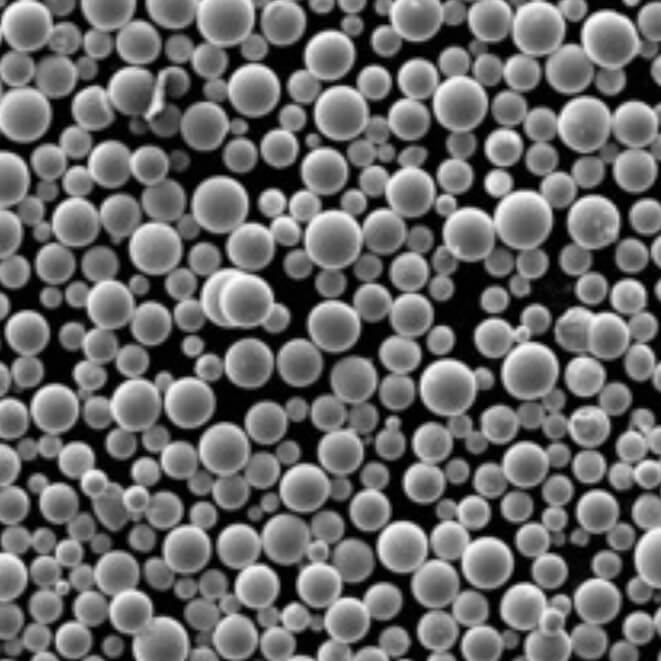

Silicon nitride powder is the foundational raw material used to manufacture silicon nitride ceramics. It is usually produced by direct nitridation or CVD-based processes and requires high purity, controlled oxygen content, and specific particle size distribution. Unlike granulated powder, it contains no binders, dispersants, or sintering additives.

The powder’s purity, morphology, and surface area determine microstructural evolution and final ceramic performance. It is widely used in slurry-based processes (tape casting, slip casting, injection molding, and feedstock preparation) and as the essential ingredient for producing granulated powder.

Typical Characteristics of Silicon Nitride Powder

| Property | Typical Range | Industrial Impact |

| Purity | 98–99.9% | Influences densification and mechanical strength |

| Oxygen content | 0.7–1.8% | Affects sintering reaction and grain growth |

| Surface area (BET) | 7–12 m²/g | Controls sintering activity |

| Particle size (D50) | 0.4–0.8 μm | Determines packing and shrinkage behavior |

Silicon Nitride Powder serves as the starting point for all advanced silicon nitride ceramics. Its properties determine whether the final ceramic can reach expected mechanical, thermal, and electrical performance levels. Because of this, powder specification control remains one of the most important steps in ceramic manufacturing.

Explore our high-quality ceramic powder products.

What Is Granulated Powder and Why Is It Needed in Industrial Forming?

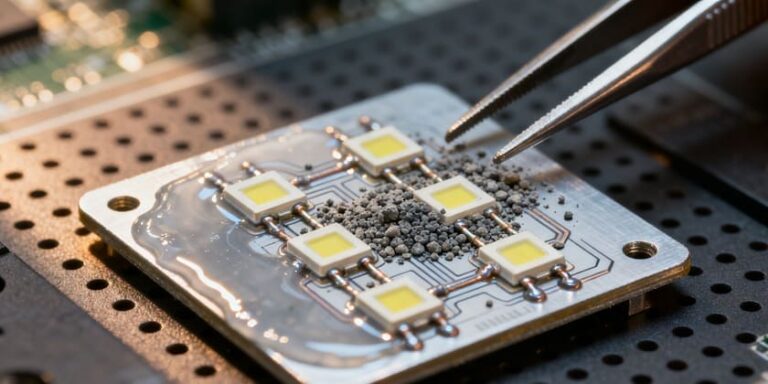

Granulated Powder is an engineered, flowable material produced by spray drying a slurry made of silicon nitride powder, sintering additives, and organic binders. Unlike raw powder, granulated powder is not intended for slurry forming—it is specifically created for pressing processes such as dry pressing or cold isostatic pressing.

Its purpose is to improve powder packing, flowability, and die filling during industrial-scale production. The addition of binders and controlled granule morphology ensures that large-scale automated pressing can proceed smoothly and consistently.

Typical Characteristics of Silicon Nitride Granulated Powder

| Parameter | Typical Value | Processing Benefit |

| Granule size | 50–120 μm | Stable die filling and flowability |

| Flowability index | 25–30 s/50 g | Supports automated powder feeding |

| Binder content | 2–6 wt% | Provides green strength |

| Additives (Y2O3, Al2O3) | 4–8 wt% | Enables liquid-phase sintering |

Granulated Powder transforms silicon nitride from a difficult-to-handle fine ceramic powder into a factory-ready, press-friendly intermediate material. The granule structure ensures stable green density and reduces variability in mass-production environments.

How Do Silicon Nitride Powder and Granulated Powder Differ in Composition?

The most essential difference lies in complexity: Silicon Nitride Powder is a pure ceramic material, while Granulated Powder contains multiple engineered additives.

These additives enable granule formation, green strength, and controlled sintering behavior. The contrast in composition directly affects microstructure uniformity and defect formation in final parts.

Composition Comparison

| Component | Silicon Nitride Powder | Granulated Powder |

| Si3N4 | 98–99.9% | 85–94% |

| Oxygen impurities | Yes | Yes |

| Sintering additives | None | Present (Y2O3, Al2O3) |

| Organic binders | None | 2–6% |

| Dispersants | None | Present |

| Moisture | Low | Slightly higher |

These compositional differences are crucial to industrial performance. The engineered additives in granulated powder significantly improve forming behavior but require a mandatory debinding step. Meanwhile, pure silicon nitride powder remains essential for wet-forming routes and customization of sintering compositions.

How Do Silicon Nitride Powder and Granulated Powder Behave Differently During Forming?

Raw silicon nitride powder cannot flow or compact effectively due to its extremely fine particle size and high surface energy. Granulated powder, in contrast, is optimized to flow smoothly and pack uniformly under pressure.

This contrast defines their forming compatibility: one for wet forming and feedstock preparation, the other for large-scale dry forming.

Forming Method Compatibility

| Forming Method | Silicon Nitride Powder | Granulated Powder |

| Slip casting | ✔ Excellent | ✘ Not suitable |

| Tape casting | ✔ Excellent | ✘ Not suitable |

| Injection molding (feedstock preparation) | ✔ Usable | ✘ Not used |

| Dry pressing | ✘ Very poor | ✔ Optimal |

| Cold isostatic pressing | ✘ Poor | ✔ Excellent |

| Automated pressing systems | ✘ Unusable | ✔ Industrial standard |

The difference is not interchangeable. Manufacturers should select powders based on forming method alignment rather than price or purity alone.

How Do Silicon Nitride Powder and Granulated Powder Affect the Sintered Microstructure?

The microstructural evolution of silicon nitride ceramics is strongly influenced by both the powder purity and the additive distribution. Pure powder provides high potential performance, while granulated powder ensures uniformity for industrial mass production.

Additives in granulated powder initiate liquid-phase sintering, producing elongated β-Si3N4 grains and high fracture toughness.

Microstructure Effects of Each Powder

Silicon Nitride Powder:

- Produces finer microstructures when used in optimized wet methods

- Allows flexible additive design

- Suitable for high-end research or specialty applications

Granulated Powder:

- Ensures homogeneous distribution of additives

- Produces consistent grain growth

- Reduces defect rate in high-volume production

Both play a foundational but different role. Raw powder enables material design freedom, while granulated powder ensures manufacturing stability.

How Do Silicon Nitride Powder and Granulated Powder Influence the Mechanical Properties of Final Ceramics?

Mechanical performance, such as hardness, toughness, and bending strength, depends heavily on microstructure uniformity, additive distribution, and residual porosity.

Granulated powder promotes uniform densification, while silicon nitride powder provides high purity that supports high strength potential when processed properly.

Mechanical Property Impact

| Mechanical Property | Silicon Nitride Powder Route | Granulated Powder Route |

| Hardness | High potential (HV 1500–1600) | Stable (HV 1450–1550) |

| Fracture toughness | High variability (6–8 MPa·m¹/²) | Highly consistent (6.5–7.5 MPa·m¹/²) |

| Bending strength | 700–1000 MPa | 850–1100 MPa |

For research applications requiring precision microstructure control, raw powder excels. For industrial environments requiring stable output, granulated powder provides superior repeatability.

How Do Silicon Nitride Powder and Granulated Powder Compare in Thermal Performance and Heat Resistance?

Thermal conductivity, thermal expansion, and temperature resistance depend strongly on sintering additive type and distribution. Since these additives differ between the two powder types, their thermal properties also diverge.

Purity and β-Si3N4 grain morphology play key roles in heat performance.

Thermal Performance Comparison

Silicon Nitride Powder:

- Higher potential thermal conductivity if optimized

- Lower impurity level improves high-temperature strength

- Suitable for electronics substrates or thermal components

Granulated Powder:

- Slightly lower maximum conductivity due to additives

- More predictable CTE and thermal uniformity

- Industrial standard for bearings, turbocharger rotors

Thermal behavior differences do not indicate superiority—only suitability for different product categories.

How Should Manufacturers Choose Between Silicon Nitride Powder and Granulated Powder?

Selection depends entirely on the forming method, production scale, and performance targets. Choosing the wrong powder often leads to forming defects, sintering failure, or inconsistent product quality.

Selection Guidance

| Requirement | Recommended Powder | Reason |

| Wet forming (slurry) | Silicon Nitride Powder | No binders, high flow in slurry |

| Automated dry pressing | Granulated Powder | Stable granule flowability |

| High-purity ceramics | Silicon Nitride Powder | Additive flexibility |

| Large-scale production | Granulated Powder | Consistency and speed |

| Research and customization | Silicon Nitride Powder | Full formulation freedom |

Correct selection minimizes risks and maximizes final mechanical and thermal performance.

Request a custom quote for our silicon nitride powder products.

What Are the Future Trends for Silicon Nitride Powder and Granulated Powder?

Future industrial demand is expected to focus on tighter control of granule morphology, improved additive systems, and powder designs tailored for emerging industries such as EVs, aerospace, and high-power electronics.

Advanced sintering technologies such as SPS and microwave sintering are also shifting powder design requirements toward more engineered forms.

Key Future Trends

- Granules with optimized internal porosity for faster debinding

- High-efficiency sintering additives designed for ultra-high thermal conductivity

- Customized powder systems for AM (additive manufacturing) ceramic processes

- Low-oxygen powder technologies for high-end industrial components

These trends show that both powder types will continue evolving rather than one replacing the other.

FAQ

| Question | Answer |

| Can granulated powder replace silicon nitride powder in slurry processes? | No. It contains binders and is unsuitable for slurry rheology. |

| Is debinding mandatory for granulated powder? | Yes. Organic binders require controlled removal. |

| Does raw powder achieve higher performance? | It can, but requires optimized processing and additives. |

| Which powder is used for mass-produced structural parts? | Granulated Powder. |

Conclusion

Silicon Nitride Powder and Granulated Powder serve completely different but equally important roles in ceramic manufacturing. The raw powder provides purity, flexibility, and suitability for wet forming, while the granulated powder offers superior flowability and consistency for industrial dry pressing and high-volume production.

Understanding their differences helps manufacturers align powder selection with forming methods, performance goals, and production scale. When properly matched to the process, both powders can deliver high-performance silicon nitride ceramics for demanding applications across automotive, electronics, aerospace, and structural industries.

Looking for a high-quality silicon nitride powder product? Contact us today!