Inconel 625 Powder 2025: Properties, Applications, and Top Suppliers

Overview of Inconel 625 Powder

Inconel 625 powder is a high-performance nickel-based alloy known for its exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. It is widely used in aerospace, marine, chemical processing, and 3D printing applications where high strength and oxidation resistance are required.

Composed mainly of nickel (Ni), chromium (Cr), molybdenum (Mo), and niobium (Nb), Inconel 625 offers outstanding mechanical properties even at cryogenic and elevated temperatures. This makes it a preferred choice for industries demanding reliability in harsh environments.

In this guide, we’ll explore the properties, applications, production methods, and best suppliers of Inconel 625 powder in 2025.

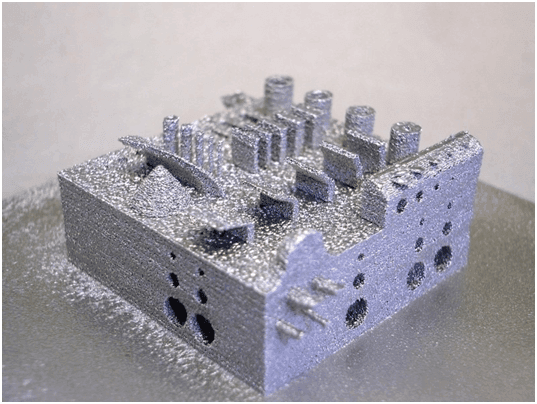

Best Inconel 625 Powder for 3D Printing

When it comes to 3D printing, Inconel 625 powder is highly valued for its excellent printability and outstanding performance in extreme conditions.

Why Choose Inconel 625 for 3D Printing?

- High-Temperature Resistance – Maintains strength up to 1000°C.

- Exceptional Corrosion Resistance – Ideal for marine and chemical processing applications.

- High Strength & Toughness – Suitable for load-bearing parts.

- Excellent Weldability – Compatible with various additive manufacturing processes.

- Oxidation Resistance – Prevents degradation even under harsh conditions.

Comparison of Inconel 625 vs. Other 3D Printing Powders

| Property | Inconel 625 | Inconel 718 | Ti6Al4V | Stainless Steel 316L | AlSi10Mg |

|---|---|---|---|---|---|

| Density (g/cm³) | 8.44 | 8.19 | 4.43 | 7.99 | 2.7 |

| Tensile Strength (MPa) | 760-1035 | 1035-1250 | 900-1100 | 485-620 | 320-450 |

| Corrosion Resistance | Excellent | Excellent | Moderate | Excellent | High |

| Temperature Resistance (°C) | 1000 | 900 | 600 | 500 | 300 |

| Cost ($/kg) | $$$$ | $$$$ | $$$$ | $$$ | $$ |

Inconel 625 is the best choice for applications demanding extreme temperature and corrosion resistance, making it an excellent material for aerospace, energy, and chemical industries.

How to Choose the Right Inconel 625 Powder

Not all Inconel 625 powders are the same. Choosing the right one depends on particle size, sphericity, production method, and purity.

Key Factors to Consider When Buying Inconel 625 Powder

- Particle Size Distribution – Typically 15-45µm for laser-based 3D printing (LPBF) and 45-75µm for binder jetting.

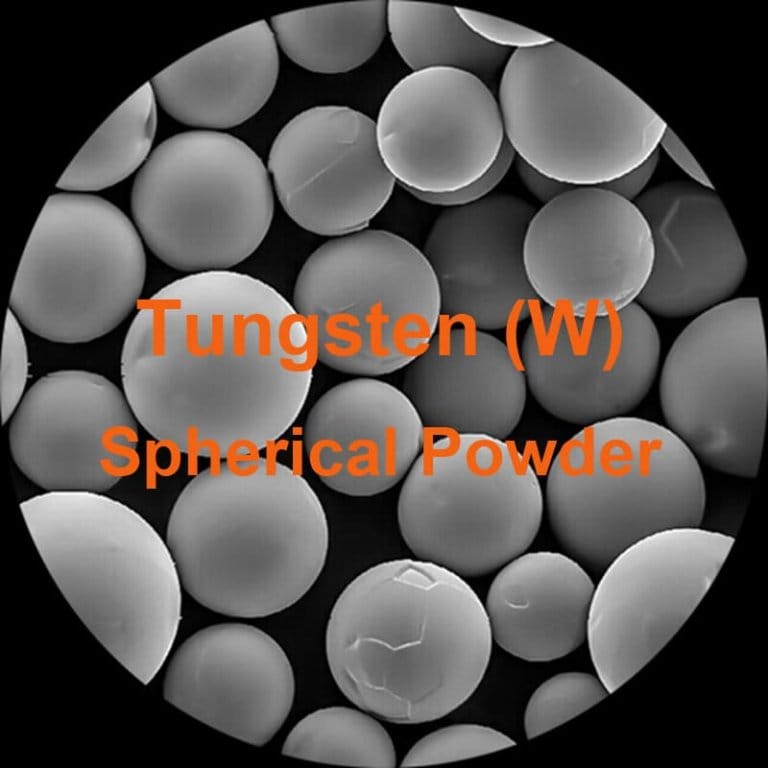

- Sphericity – Highly spherical powders ensure better flowability and denser packing.

- Purity – Low oxygen and sulfur content improves mechanical performance.

- Production Method – Gas atomization and PREP provide superior powder quality.

- Application Compatibility – Ensure the powder is optimized for your specific 3D printing or manufacturing process.

Why Choose Heeger Materials Inc. ?

Heeger Materials Inc. is a trusted supplier of high-quality Inconel 625 powder, utilizing cutting-edge Vacuum Induction Gas Atomization (VIGA) and Plasma Rotating Electrode Process (PREP) techniques to ensure excellent sphericity and purity.

If you need premium Inconel 625 powder with high performance and reliability, Heeger Materials is an excellent choice.

Top Inconel 625 Powder Suppliers in 2025

Finding a reliable supplier is essential to ensure consistent quality and performance in high-end applications.

Leading Inconel 625 Powder Suppliers

| Supplier Name | Country | Specialization | Production Methods | Website |

|---|---|---|---|---|

| Heeger Materials Inc. | USA | 3D Printing Powders | VIGA, PREP, EIGA | Visit Site |

| AP&C (GE Additive) | Canada | Aerospace & Medical | Plasma Atomization | N/A |

| Höganäs | Sweden | Metal Powders | Gas & Water Atomization | N/A |

| EOS GmbH | Germany | Additive Manufacturing | Gas Atomization | N/A |

Why Heeger Materials?

- 40+ years of expertise in powder metallurgy.

- Advanced atomization processes ensuring high-quality spherical powders.

- Strong collaborations with universities, research institutes, and aerospace companies.

- Competitive pricing and global distribution.

Looking for premium Inconel 625 powder? Get in touch with us today!

Properties

Physical and Mechanical Properties

| Property | Value |

|---|---|

| Density | 8.44 g/cm³ |

| Melting Point | 1290-1350°C |

| Tensile Strength | 760-1035 MPa |

| Yield Strength | 480-690 MPa |

| Elongation | 30-50% |

| Hardness | 180-230 HV |

| Thermal Expansion | 12.8 x10⁻⁶/K |

Why These Properties Matter?

- High Strength & Toughness – Ideal for aerospace and heavy-duty applications.

- Excellent Corrosion Resistance – Performs well in seawater, acidic, and high-temperature environments.

- Superior Temperature Resistance – Maintains mechanical integrity even at extreme temperatures.

Discover our full range of nickel-based alloy powders.

Applications of Inconel 625 Powder in Industry

Inconel 625 is used in high-stress environments where strength, temperature resistance, and corrosion resistance are critical.

Top Applications

| Industry | Application Example | Benefits |

|---|---|---|

| Aerospace | Jet engine components, turbine blades | High temperature & oxidation resistance |

| Marine | Submarine parts, offshore oil rigs | Excellent seawater corrosion resistance |

| Chemical Processing | Heat exchangers, reactors | Resistant to acids and corrosive chemicals |

| Energy | Nuclear reactors, power plants | Withstands extreme heat and stress |

With the increasing use of 3D printing in high-performance industries, Inconel 625 powder is becoming a preferred material for critical applications.

Contact us for customized Inconel 625 powder solutions.

Quality Standards

Ensuring that Inconel 625 powder meets stringent quality standards is essential for achieving consistent performance in aerospace, marine, and industrial applications. High-quality powders reduce defects, improve mechanical properties, and enhance the longevity of the final component.

Key Quality Standards

| Standard | Description |

|---|---|

| ASTM B446 | Standard specification for Inconel 625 bars and forgings. |

| ASTM F3055 | Specification for nickel-based alloy powder in additive manufacturing. |

| AMS 5666 | Aerospace Material Specification for Inconel 625 powder. |

| ISO 9001 | Quality management system ensuring consistency in production. |

| NADCAP | Certification for aerospace and defense applications to ensure process quality. |

Why Buy Certified Inconel 625 Powder?

- Ensures Consistency – Certified powders have controlled particle size, shape, and purity.

- Improves Mechanical Properties – Meets strength, hardness, and corrosion resistance requirements.

- Enhances Printability – Reduces porosity, cracking, and defects in 3D printing.

- Compliance with Industry Regulations – Essential for aerospace, energy, and medical applications.

Heeger Materials Inc. strictly adheres to these quality standards, providing high-quality Inconel 625 powder that meets industrial and aerospace requirements.

Cost Analysis

The price of Inconel 625 powder depends on several factors, including the production method, purity, and particle size distribution. Below is a breakdown of the pricing factors and market trends.

Factors Affecting Inconel 625 Powder Cost

- Production Method – Gas atomization and PREP are more expensive but provide high-quality spherical powder.

- Particle Size Distribution – Finer powders (15-45µm) for LPBF are costlier than coarser powders.

- Purity Levels – Low oxygen and sulfur content powders command a premium.

- Supplier & Location – Prices vary based on region, supplier, and logistics costs.

Price Comparison of Inconel 625 vs. Other Metal Powders

| Powder Type | Cost ($/kg) | Common Use Case |

|---|---|---|

| Inconel 625 | 150−150 – 150−400 | Aerospace, marine, 3D printing |

| Inconel 718 | 100−100 – 100−350 | High-temperature applications |

| Ti6Al4V | 300−300 – 300−600 | Medical, aerospace |

| Stainless Steel 316L | 80−80 – 80−150 | General engineering |

| AlSi10Mg | 50−50 – 50−120 | Automotive, lightweight structures |

While Inconel 625 is more expensive, its superior corrosion resistance, high-temperature strength, and durability make it a preferred choice for critical applications.

Request a custom quote for bulk orders of Inconel 625 powder.

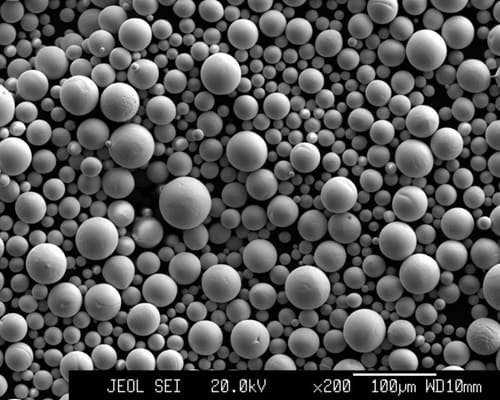

Particle Size and Shape

The particle size and morphology of Inconel 625 powder significantly impact its flowability, packing density, and final component properties.

Why Particle Size Matters

- Fine Powder (15-45 µm) – Best for laser powder bed fusion (LPBF) and selective laser melting (SLM).

- Medium Powder (45-75 µm) – Used in binder jetting and direct energy deposition (DED).

- Coarse Powder (75-150 µm) – Suitable for metal injection molding (MIM) and cold spray applications.

Spherical vs. Irregular Powder: Which is Better?

| Powder Shape | Characteristics | Best Application |

|---|---|---|

| Spherical | Excellent flowability, uniform packing, low porosity | 3D printing, SLM, LPBF |

| Irregular | Lower flowability, higher porosity, cheaper production | MIM, binder jetting |

Gas-atomized spherical Inconel 625 powder is preferred for 3D printing due to its superior flowability, density, and minimal defects.

Explore our high-quality spherical nickel alloy powders.

Production Methods

Different powder production methods impact the particle shape, purity, and cost of Inconel 625 powder.

Comparison of Production Methods

| Production Method | Particle Shape | Purity | Cost | Best Use Case |

|---|---|---|---|---|

| Gas Atomization | Spherical | High | $$$ | 3D Printing, Aerospace |

| Water Atomization | Irregular | Medium | $$ | MIM, Binder Jetting |

| PREP (Plasma Rotating Electrode Process) | Highly Spherical | Very High | $$$$ | Aerospace, Medical |

Gas atomization is the most widely used method for high-quality Inconel 625 powder, ensuring excellent sphericity and low oxygen content.

Heeger Materials utilizes advanced gas atomization and PREP techniques to produce premium spherical Inconel 625 powder for critical applications.

FAQ

| Question | Answer |

|---|---|

| What is Inconel 625 powder used for? | It’s used in aerospace, marine, energy, and chemical industries for high-temperature and corrosion-resistant applications. |

| Why is Inconel 625 preferred for 3D printing? | It offers excellent strength, weldability, and resistance to extreme environments. |

| What is the difference between Inconel 625 and Inconel 718? | Inconel 625 has better corrosion resistance, while Inconel 718 has higher strength and hardness. |

| What is the typical particle size for Inconel 625 powder? | 15-45µm for LPBF and 45-75µm for binder jetting. |

| Where can I buy high-quality Inconel 625 powder? | Heeger Materials Inc. provides premium Inconel 625 powder for industrial applications. |

Conclusion

Inconel 625 powder is one of the most versatile and reliable nickel-based alloys for high-performance applications. Its exceptional corrosion resistance, high-temperature strength, and durability make it a preferred choice for industries like aerospace, energy, and chemical processing.

For the best quality Inconel 625 powder, Heeger Materials Inc. offers high-purity, spherical powders produced using advanced atomization techniques.

Looking for premium Inconel 625 powder? Contact us today!