Metal Powder Materials for 3D printing

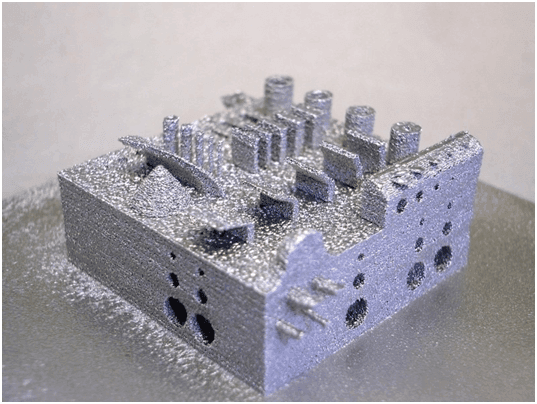

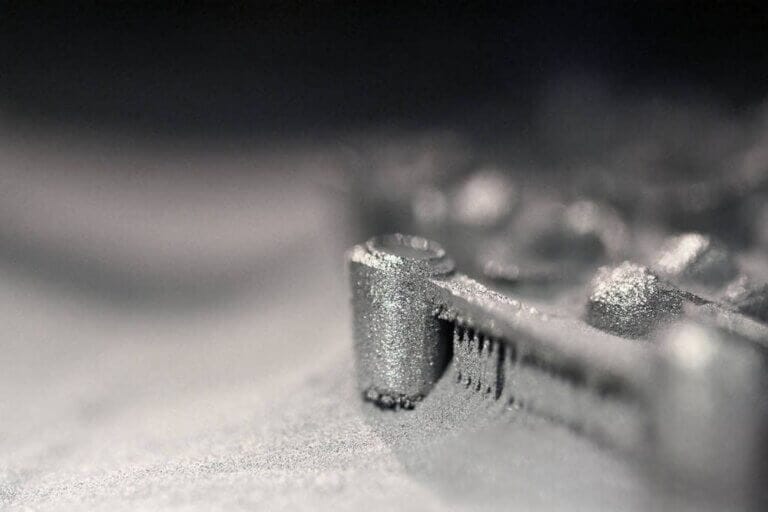

Metal 3D printing, also known as metal powder sintering (SLM), utilizes metal powder to directly print metal parts. The metal powders used in 3D printing require good plasticity, as well as small particle size, narrow particle size distribution, high sphericity, good fluidity, and high bulk density. Commonly used metal powders in 3D printers include stainless steel, aluminum alloys, cobalt-chromium alloys, copper alloys, titanium alloys, and nickel alloys. Among these, iron-based alloys are the most important in engineering technology, with widespread applications in industries such as aerospace, automotive, marine, and machinery manufacturing due to their ability to mold complex structures.

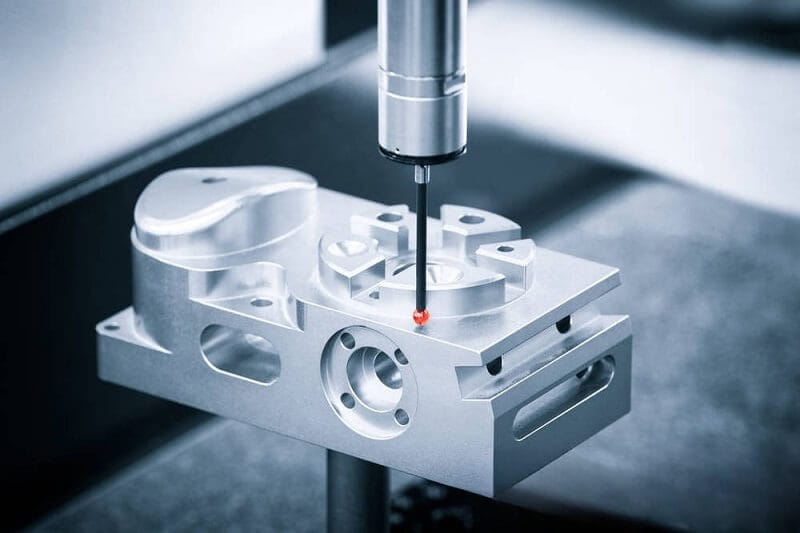

Spherical powder plays a crucial role in 3D printing, offering superior properties that enhance print quality, speed, and efficiency while enabling the creation of complex designs.

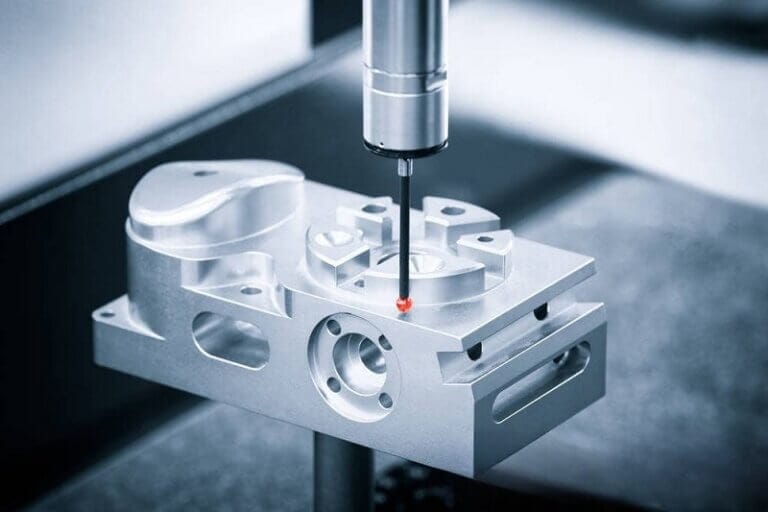

The metal powder type and the 3D printing process employed determine the properties of the end product

Stainless Steel Powder

- It is a relatively inexpensive metal printing material, offering cost-effective solutions with good corrosion resistance and high strength, making them suitable for fast and efficient manufacturing of complex industrial parts in small quantities.

Aluminum alloy powder

- Main aluminum alloys in metal 3D printing: AlSi12 & AlSi10Mg. AlSi12 offers good thermal properties; AlSi10Mg has high strength & stiffness, ideal for thin-walled & complex geometries with low weight. Printed aluminum parts have comparable or better mechanical properties than cast parts, at a reduced cost of up to 30%.

Cobalt-Chromium Alloy Powder

- It is widely used in metal 3D printing for artificial joints, orthopedic implants, and dental applications, thanks to its exceptional wear and corrosion resistance.

Copper Alloy Powder

- It is known for its outstanding thermal and electrical conductivity and is often utilized in 3D printing for thermal management purposes. Its excellent thermal conductivity allows for effective heat dissipation, while the design flexibility of 3D printing enables the creation of complex internal structures and custom-shaped cooling channels.

Titanium Alloy Powder

- It is widely used in the aerospace industry. 3D printing optimizes product design by replacing solid structures with lightweight, complex designs, resulting in better mechanical properties and cost-effective production.

Nickel Alloy Powder

- It offers excellent oxidation and corrosion resistance, making them ideal for high-temperature and high-pressure environments. They form a protective oxide layer when heated, ensuring long-term durability and mechanical stability.

Advanced Powder Tech is a professional supplier of various kinds of Spherical Powder. We offer customized solutions and deliver high-quality products that are tailored to meet specific requirements.