0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder – 0Cr25Ni20Mo2 Alloy Powder – Additive Manufacturing – 3D Printing

0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder: We offer a wide range of high-quality, customizable spherical metal powders in various particle sizes, available in stock with fast lead times. Our products cater to large-scale projects and specific client needs, making them ideal for aerospace, marine, and defense applications.

Description

0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powderx – Optimized for Additive Manufacturing

0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powderx is expertly crafted for 3D printing, delivering superior performance in precision-demanding sectors like aerospace, automotive, and medical industries. Utilizing advanced atomization techniques, this premium powder features highly spherical particles for enhanced flowability and packing density. This improves printing process, layer adhesion, and results in outstanding surface finishes. Ideal for laser and electron beam powder bed fusion technologies, 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder is your key to efficient, high-quality outputs.

Typical Chemical Compositions and Specifications

Our 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder powder meets rigorous industry standards:

| SKU# | Product | Purity | Particle Size | Standard Packaging |

|---|---|---|---|---|

| HMSP0182-1 | 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder | Customized | 1-10um | 1kg, 5 kgs, 25 kgs |

| HMSP0182-2 | 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder | Customized | 5-15um | 1kg, 5 kgs, 25 kgs |

| HMSP0182-3 | 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder | Customized | 5-25um | 1kg, 5 kgs, 25 kgs |

| HMSP0182-4 | 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder | Customized | 15-45um | 1kg, 5 kgs, 25 kgs |

| HMSP0182-5 | 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder | Customized | 15-53um | 1kg, 5 kgs, 25 kgs |

| HMSP0182-6 | 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder | Customized | 45-105um | 1kg, 5 kgs, 25 kgs |

| HMSP0182-7 | 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder | Customized | 53-331um | 1kg, 5 kgs, 206 kgs |

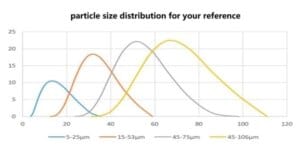

Particle Size Distribution (PSD)

The Particle Size Distribution (PSD) of spherical metal powders is crucial for high-performance applications like 3D printing and metallurgy. Our powders feature a tightly controlled PSD for optimal flowability, packing density, and consistent results. Ideal for precision-demanding industries.| Particle Size | Particle Size Description | PSD (Malvern laser particle size analyzer) |

||

|---|---|---|---|---|

| 15-45μm | D10=15-20μm | D50=25-30μm | D90=35-40μm |  |

| 15-53μm | D10=15-20μm | D50=25-35μm | D90=45-50μm | |

| 5-25μm | D10=5-10μm | D50=15-20μm | D90=20-25μm | |

| 45-75μm | D10=45-55μm | D50=55-65μm | D90=70-75μm | |

| 45-105μm | D10=50-60μm | D50=75-85μm | D90=95-105μm | |

| 75-150μm | D10=80-90μm | D50=110-125μm | D90=135-150μm | |

*Custom PSDs (Particle Size Distributions) available upon request.

Applications of 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder

- Additive Manufacturing: Enables complex designs and lightweight structures.

- Powder Metallurgy: Facilitates the creation of dense, uniform parts.

- Aerospace Components: Produces high-strength, lightweight parts for aircraft.

- Automotive Industry: Enhances fuel efficiency with precision components.

- Biomedical Devices: Supports the development of custom, biocompatible implants.

- Coatings: Provides superior wear resistance for thermal spray applications.

Product Notes, Packaging, and Shipping

- Packaging Options: Available in 1kg, 5kg, and 25kg containers. Custom packaging available.

- Shipping via UPS, DHL, FedEx, and more.

- Delivery Times: 1-2 weeks for stock items, 4-5 weeks for custom orders.

Where to Purchase 0Cr25Ni20Mo2 Stainless Steel Alloy Spherical Powder in Bulk?

We are a leading supplier and manufacturer of high-quality Spherical Powder. Leveraging extensive expertise, we offer competitive pricing and customized solutions to ensure exceptional quality and customer satisfaction.

Additional information

| Molecular Formula / Grade | 0Cr25Ni20Mo2 |

|---|---|

| Particle Size | 2-10um, 5-15um, 5-25um, 15-45um, 15-53um, 45-105um, 53-150um, Customized |

| Production Method | VIGA, EIGA, PREP, WA, PDR, CA |

| Purity | NA |

| Schedule B | NA |

| CAS | NA |

| Melting Point | NA |

| Boiling Point | NA |

| Density | NA |

| Composition | 0Cr25Ni20Mo2 |

| Morphology | Spherical |