Thermal Spray Coating: Materials, Processes, and Bonding Mechanisms

Thermal spraying is a surface engineering technology that accelerates molten or semi-molten material particles onto a substrate at high velocity to form functional coatings. Since the Swiss inventor Schori developed the first flame spray gun in the early 20th century, thermal spraying has evolved for over 110 years and become an indispensable surface modification method in modern industry.

Thermal spray coatings are widely used in aerospace, energy, automotive, biomedical, petrochemical, printing, and steel industries, providing wear resistance, corrosion resistance, high-temperature oxidation resistance, thermal barrier, electrical conductivity/insulation, biocompatibility, and other functions.

This article systematically introduces thermal spray materials, major processes, coating formation mechanisms, and bonding principles to provide readers with a comprehensive understanding.

At Advanced Powder Tech, we specialize in high-quality thermal spray coating materials with various forms and specifications, ensuring optimal performance for industrial and scientific applications.

Thermal Spray Coating Materials Classification

Thermal spray feedstock covers virtually all solid engineering materials. They are generally classified into five major categories:

| Material Category | Typical Examples | Key Properties & Applications |

| Pure Metals & Alloys | Ni, Al, Zn, Cu, NiCr, NiAl, stainless steel, Co-based alloys | Sacrificial corrosion protection, wear & corrosion resistance |

| Cermets | WC-Co, WC-CoCr, Cr₃C₂-NiCr, TiC-NiMo | Ultra-high hardness, wear resistance at elevated temperature (aero-engines, rolls) |

| Oxide Ceramics | Al₂O₃, ZrO₂-8Y₂O₃ (YSZ), Cr₂O₃, TiO₂ | Wear resistance, thermal insulation, electrical insulation, thermal barrier coatings (TBC) |

| Carbides, Borides, Nitrides | SiC, B₄C, TiN, CrN | Extreme hardness, wear & oxidation resistance |

| Polymers & Composites | PEEK, PTFE, Ni-graphite, Al-polyester | Self-lubrication, abradable seals, sealing layers |

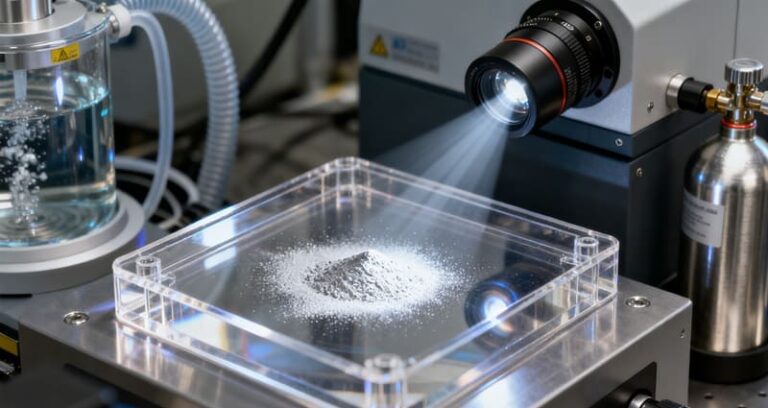

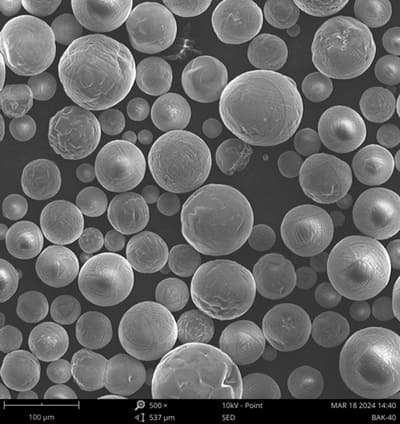

Feedstock forms include powders (most common, 10–100 μm), wires, rods, and suspensions. Powders can be further divided into agglomerated & sintered, fused & crushed, clad, and composite types. The manufacturing route directly influences particle morphology, flowability, and in-flight behavior during spraying.

Material selection guidelines:

- Match the coefficient of thermal expansion (CTE) with the substrate to minimize residual stress

- Meet service environment requirements (temperature, corrosive media, loading)

- Ensure good melting and flight stability

- Balance performance with cost and sprayability

Looking for high-quality thermal coating materials? Explore Advanced Powder Tech’s selection.

Thermal Spray Processes – Classification and Principles

More than ten mature thermal spray processes are used industrially today. The table below compares key parameters of mainstream techniques:

| Process | Heat Source | Particle Velocity (m/s) | Particle Temperature (°C) | Typical Bond Strength (MPa) | Porosity (%) | Oxidation Level | Typical Thickness (μm) |

| Conventional Flame Spraying | Oxy-acetylene flame | 50–150 | 2500–3000 | 10–30 | 10–20 | High | 100–2000 |

| HVOF / HVAF | Supersonic combustion | 500–1000 | 2500–3200 | 60–80+ | <2 | Low | 50–500 |

| Atmospheric Plasma Spraying (APS) | Plasma arc | 200–500 | 8000–15000 | 30–70 | 2–10 | Medium | 50–1000 |

| Vacuum / Low-Pressure Plasma (VPS/LPPS) | Vacuum plasma | 300–600 | 8000–15000 | 70–100 | <1 | Extremely low | 50–500 |

| Arc Spraying | Twin-wire electric arc | 150–300 | 4000–6000 | 20–50 | 5–15 | High | 100–2000 |

| Cold Spraying | High-pressure gas (no melting) | 500–1200 | <1000 | 50–100 | <1 | None | 50–5000 |

| Detonation Spraying (D-Gun) | Cyclic detonation | 800–1000 | 3000–4000 | 80+ | <2 | Low | 50–300 |

Each process has its sweet spot:

- HVOF/HVAF is the gold standard for wear-resistant carbide coatings (WC-Co, Cr₃C₂-NiCr), achieving hardness >1200–1400 HV.

- APS remains the workhorse for thermal barrier coatings; over 90% of aero-engine turbine blades worldwide use APS 8YSZ.

- Cold spray is unique in depositing fully solid-state particles, enabling oxygen-free copper, aluminum, titanium, and even amorphous alloys.

- VPS/LPPS is preferred for high-performance MCrAlY bond coats and as an alternative to EB-PVD.

Explore our optimized thermal spray coating materials.

Thermal Spray Coating Formation Mechanism

Coating buildup occurs in four distinct stages:

- In-flight heating and acceleration of particles (milliseconds)

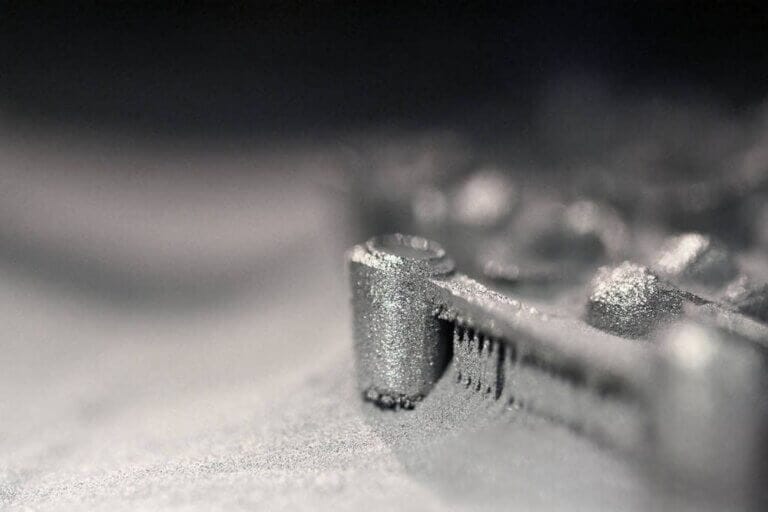

- High-velocity impact and severe plastic deformation, forming disk-shaped “splats”

- Layer-by-layer stacking of subsequent particles

- Cooling and contraction, generating residual stresses that affect cohesion and adhesion

Individual splats exhibit a characteristic pancake morphology (50–200 μm diameter, 1–5 μm thick) with dense centers and splashed edges. The resulting coating displays a lamellar microstructure containing pores, oxide inclusions, unmelted particles, and microcracks.

Thermal Spray Coating Bonding Mechanisms

Bonding between coating and substrate is not a classic weld but a combination of several mechanisms:

| Bonding Mechanism | Description | Typical Processes & Materials | Approximate Contribution |

| Mechanical Interlocking | Molten droplets fill roughness valleys created by grit blasting (“anchor effect”) | Van der Waals forces, hydrogen bonding, and electrostatic attraction | 60–90% |

| Metallurgical/Chemical | Localized micro-melting, diffusion, or exothermic reactions (e.g., Ni-Al) | HVOF NiAl bond coats, VPS MCrAlY, self-bonding | 10–40% |

| Physical Bonding | Van der Waals forces, hydrogen bonding, electrostatic attraction | Low-temperature processes, polymers | <5% |

| Hybrid Mechanisms | Multiple mechanisms acting simultaneously | Most real-world coatings | 100% |

In practice, mechanical interlocking dominates, but metallurgical bonding can dramatically increase adhesion (from ~30 MPa to >80 MPa).

Key factors influencing bond strength:

- Substrate surface roughness and cleanliness

- Preheating temperature (removes adsorbed moisture, reduces thermal shock)

- Particle temperature and velocity (higher values favor metallurgical bonding)

- Use of dedicated bond coats (NiCrAlY, NiAl, etc.)

Request a custom quote for high-quality thermal spray coating materials.

Thermal Spray Coating Properties and Characterization

Typical properties of thermal spray coatings:

| Property | Typical Range | Representative Coatings |

| Microhardness | 300–1400 HV₀.₃ | WC-Co >1200, Al₂O₃ ~1000 |

| Bond Strength | 20–100+ MPa | VPS MCrAlY >90 MPa |

| Porosity | 0.5–20% | HVOF <2%, flame spray >10% |

| Thermal Conductivity | 0.8–30 W/m·K (YSZ) to ~80 W/m·K (pure metals) | YSZ TBC ~1 W/m·K |

| Corrosion Resistance | Salt-spray life >5000 h | Sealed Zn/Al, Cr₃C₂-NiCr |

Common characterization techniques: SEM+EDS, XRD, tensile adhesion testing (ASTM C633), image analysis for porosity, nano-indentation, thermal cycling tests, etc.

What Are the Typical Applications of Thermal Spray Coating?

In essence, thermal spray coating is a process where finely powdered metallic or non-metallic materials are melted (or heated to a plastic state) and accelerated in a gas stream towards a prepared surface. The particles splat onto the surface, cool, and build up to form a lamellar, adherent coating.

The typical applications are vast, but they can be grouped into a few key functional categories.

1. Wear Resistance

This is the most common application of thermal spray coatings. They are used to protect components from various types of wear, including abrasion, adhesion, erosion, and fretting.

- Aerospace: Landing gear components, turbine shaft seals, actuator pistons.

- Automotive: Piston rings, synchronizer rings, valve stems.

- Power Generation: Fan blades, pump seals, boiler tube hangers in coal-fired plants.

- Industrial Machinery: Hydraulic piston rods, rolls for paper and steel mills, screw conveyors, textile guides.

- Agriculture: Tiller blades, cultivator sweeps, and combine harvester components.

2. Corrosion & Oxidation Protection

Coatings provide a sacrificial or barrier layer to protect the underlying substrate (often a less expensive material like mild steel) from corrosive environments and high-temperature oxidation.

- Marine & Offshore: Ship hulls, ballast tanks, offshore platform components.

- Infrastructure: Steel bridges, highway gantries, lock gates.

- Chemical Processing: Vessels, valves, and pipes exposed to corrosive chemicals.

- High-Temperature: Boiler water walls, superheater tubes, turbine blades, and vanes in jet engines and power turbines.

3. Thermal Barrier Coatings (TBCs)

These are highly specialized ceramic coatings (like Yttria-Stabilized Zirconia – YSZ) with low thermal conductivity. They insulate metallic components from extreme heat, allowing them to operate at higher temperatures or with improved efficiency.

- Aerospace Jet Engines: Turbine blades, combustor cans, and nozzle guide vanes.

- Power Generation Turbines: Hot-section components to increase inlet temperatures and efficiency.

- Automotive: Piston crowns and exhaust manifolds in high-performance engines.

4. Repair & Salvage of Components

This is a hugely cost-effective application. Worn or mismatched components can be built back up to their original dimensions (or even larger) with thermal spray, saving the cost of replacement.

- Repair of Shafts and Bearing Journals: On electric motors, pumps, and gearboxes.

- Salvage of Casting Defects: Filling porosity in cast parts before they are put into service.

- Rebuilding Worn Rolls: In the printing, paper, and steel industries.

5. Control of Clearances & Dimensions

Coatings can be applied to control the size and clearances between mating parts, often providing better performance than the base material alone.

- Aerospace: “Abradable” coatings are sprayed onto engine casings. The rotating blades wear a precise path into this soft coating, creating a perfect, minimal-clearance seal that improves engine efficiency.

- General Machinery: Wear rings and seals in pumps and compressors.

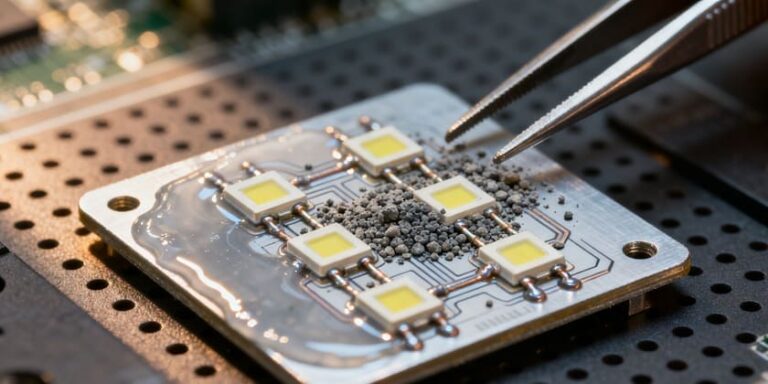

6. Restoration of Electrical Properties

While less common, certain thermal spray materials can be used to apply or restore conductive or resistive surfaces.

- Conductive Coatings: Applying copper or aluminum coatings for electrical grounding or EMI/RFI shielding.

- Resistive Coatings: Applying heating elements directly onto surfaces like glass or ceramic.

Current Challenges and Future Trends

Major challenges:

- Porosity and oxidation remain difficult to eliminate completely

- Bond strength and fatigue performance still lag behind bulk materials

- Residual stresses can cause cracking

- High equipment and operating costs (especially vacuum plasma)

Promising directions:

- Supersonic plasma spraying and nanostructured/ fine-grained coatings

- Solution Precursor Plasma Spraying (SPPS) and Suspension Plasma Spraying (SPS) → columnar microstructures approaching EB-PVD performance

- Cold spray for repair and additive manufacturing (e.g., restoring superalloy damage, 3D-printing copper heat exchangers)

- AI + robotic spraying + real-time infrared monitoring + digital twins

- Green processes: water-based suspensions, low-noise arcs, reduced hazardous emissions

Conclusion

Thermal spraying, with its wide material selection, flexible processes, diverse coating functions, and repairability, holds an irreplaceable position in high-end manufacturing and remanufacturing. With the continuous emergence of new materials, processes, and intelligent equipment, thermal spraying will play an even greater role in carbon neutrality goals, next-generation aero-engines, and deep-sea/space equipment.

For top-quality thermal spray coating materials, Advanced Powder Tech provides tailored solutions for various applications.

Looking for premium thermal coating materials? Contact us today!

.jpg)