Why Metal Injection Molding Is Reshaping the Future of Consumer Electronics

Metal Injection Molding (MIM) has rapidly become one of the most influential manufacturing technologies in the consumer electronics sector. As devices become thinner, lighter, and more functionally integrated, traditional machining and stamping methods face limitations in producing micro–precision parts at scale. MIM bridges this gap by combining powder metallurgy with injection molding, enabling mass production of complex metal components with high density, strength, and dimensional stability. This article examines why MIM is revolutionising consumer electronics, how the technology operates, the materials that drive it, and its comparison to conventional processes.

At Advanced Powder Tech, we specialise in high-quality powder products, ensuring optimal performance for industrial and scientific applications.

What Is Metal Injection Molding and Why Does It Matter to Consumer Electronics?

Metal Injection Molding is a hybrid manufacturing process that merges fine metal powders with polymer binders to form feedstock pellets that can be injection-molded like plastics. After shaping, the binder is removed, and the parts are sintered to near-full density. This unique combination brings plastic-like design freedom to metallic components.

MIM matters to consumer electronics because devices demand small, intricate, and high-strength parts that must be produced in extremely high volumes. From smartphone hinges to smartwatch housings, MIM enables the fabrication of parts that cannot be machined or stamped economically. Its advantages include near-net shaping, micron-level accuracy, and high repeatability.

Key Physical Characteristics of MIM vs. Conventional Processes

| Attribute | MIM | CNC Machining | Metal Stamping |

| Density | 96–99% | ~100% | ~95% |

| Minimum Feature Size | < 0.2 mm | ~0.8 mm | >0.5 mm |

| Geometric Complexity | Very high | Moderate | Low |

| Production Volume | Very high | Low–medium | High |

These characteristics explain why MIM is becoming a foundational manufacturing route for next-generation digital devices.

Explore our high-quality powder products.

How Does the MIM Process Work and Why Is It Critical for Consumer Electronics?

The MIM process involves four steps: mixing metal powders with binders, injection molding, debinding, and sintering. Each stage affects microstructure, final density, and dimensional precision. For consumer electronics, consistency across millions of parts is essential, making process control a top priority.

Because consumer electronics parts often exhibit extremely thin walls, small radii, and hidden internal structures, MIM’s ability to fill complex mold cavities with highly flowable feedstock becomes indispensable. The high-pressure molding environment ensures that fine features replicate accurately.

Four Core Stages of the MIM Workflow

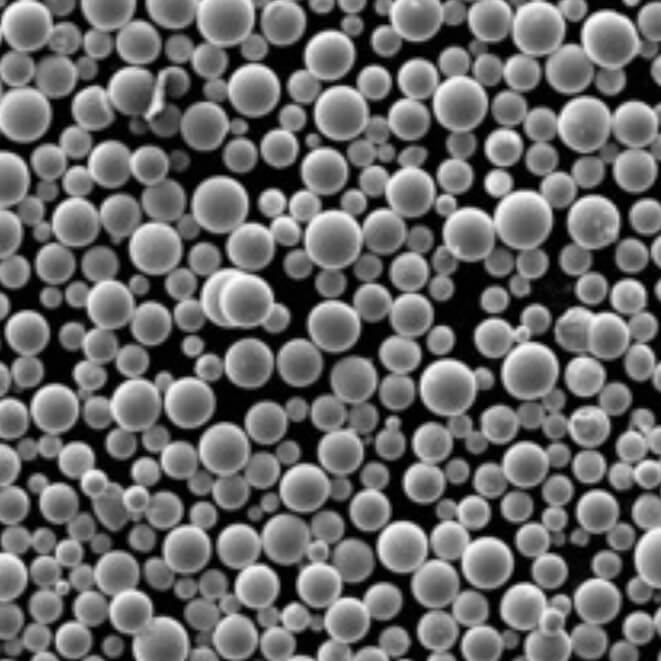

- Feedstock Preparation – Fine powder (<20 μm) blended with binder for uniform flow.

- Injection Molding – Feedstock is molded into near-net shapes with minimal scrap.

- Debinding – Thermal or solvent processes remove organic binders.

- Sintering – High-temperature densification achieves final strength and dimensional accuracy.

Each step contributes directly to part consistency, which is crucial in mobile phones, wearables, and miniature connectors.

Why Is Metal Injection Molding Ideal for Consumer Electronics?

Consumer electronics require components that combine compact size, mechanical reliability, magnetic neutrality, and aesthetic refinement. MIM excels in these areas because it produces dense metal parts with smooth surfaces and high structural integrity.

Another reason MIM fits consumer electronics is its ability to integrate multiple features into a single part. Instead of assembling 10–20 machined components, manufacturers can produce a single integrated MIM piece that improves durability and reduces assembly time.

Why MIM Outperforms Competing Methods in Electronics

| Requirement | Injection Molding Advantage | Example Electronic Component |

| High Dimensional Accuracy | ±0.03 mm | Multi-camera lens brackets |

| Miniaturization | Features <0.2 mm | Smartwatch internal frames |

| Non-magnetic Options | 316L, 304L stainless steel | Autofocus/OIS components |

| High Strength | Up to 1000 MPa for 17-4PH | Smartphone hinge gears |

MIM’s comprehensive advantages explain its explosive adoption across the mobile and wearable device industries.

Which Metal Injection Molding Materials Work Best for Consumer Electronics?

Different consumer electronics require different mechanical, magnetic, and corrosion-resistance properties. As a result, material selection plays a critical role. Nitrogen-atomised stainless steel powders—especially 304L, 316L, and 17-4PH—dominate the field due to their fine particle distribution, low oxygen content, and excellent sintering behaviour.

MIM powders for electronics typically range from 5–20 μm to ensure high packing density and smooth surface finish. These powders enable ultra-precise micro-structures such as snap-fits, miniature gears, and optical brackets.

Common MIM Materials for Consumer Electronics

| Material | Key Property | Typical Applications |

| 316L | Non-magnetic, corrosion-resistant | Camera brackets, smartwatch bezels |

| 17-4PH | High strength, hardenable | Smartphone hinges, structural joints |

| 304L | Affordable, ductile | Charging connectors, internal brackets |

| Titanium Alloy | Lightweight, biocompatible | Premium wearables |

Fine powder quality directly enhances sintered density and reduces deformation—critical requirements for display hinges and micro-connector pins.

Request a custom quote for our powder products.

How Does MIM Compare With CNC, Stamping, and Die Casting in Consumer Electronics?

When benchmarking manufacturing methods, MIM offers the best balance between complexity, performance, and mass-production scalability. CNC machining offers excellent accuracy but generates significant waste and becomes expensive at high volumes. Stamping is economical but limited to simple shapes. Die casting produces near-net shapes but suffers from lower strength and larger feature limitations.

MIM uniquely delivers complexity, high strength, and mass-production capability simultaneously.

Comparative Advantages of MIM

- Higher geometric freedom than CNC and stamping

- Higher production throughput than CNC machining

- Higher strength and density than die casting

- Lower material waste due to near-net forming

- Superior consistency for multi-million-unit consumer electronics parts

This makes MIM especially attractive for smartphone hinges, wearables, charging connectors, and earbuds.

How Is MIM Powering Next-Generation Miniaturised Consumer Electronics?

The miniaturisation race requires parts that are smaller, stronger, and more integrated than ever before. MIM enables the industry to achieve sub-millimetre features while maintaining functional robustness.

In smartphones, MIM is used for hinge gears, camera housings, SIM-card trays, internal structural frames, and connector components. In wearables, MIM enables ultra-compact housings, mechanical switches, and magnetic latch components.

Typical MIM Components in Consumer Electronics

| Category | Examples | Key MIM Benefit |

| Smartphones | OIS brackets, hinges, connector parts | Miniaturization + strength |

| Wearables | Watch cases, internal brackets | Lightweight + corrosion resistance |

| Audio Devices | TWS hinge parts, charging contacts | High-volume production |

| Laptop/Tablet | Hinge arms, mechanical pivots | High fatigue life |

These high-performance components directly enable ultra-thin designs and advanced mechanical durability.

What Trends Will Shape the Future of Metal Injection Molding in Consumer Electronics?

The next decade will bring new powders, new hardware, and deeper integration of process intelligence. Powder metallurgy continues to develop tighter particle distributions and lower oxygen levels, enabling finer features.

Automation and AI will be integrated across debinding and sintering lines to predict dimensional deviation and reduce scrap rates. Meanwhile, ultra-fine powders (<10 μm) are enabling MIM micro-components for robotics and medical electronics.

Future Trends of MIM in Electronics

- Material diversification – titanium, tungsten alloys, magnetic alloys

- Micro-MIM components for advanced sensors and MEMS

- AI-driven manufacturing for tolerance prediction

- Integration with 3D-printed metal tooling to shorten development cycles

These innovations will continue pushing MIM toward even smaller and more advanced applications.

FAQ

| Question | Answer |

| Can MIM replace CNC completely? | What is the tolerance range? |

| Is MIM suitable for magnetic-sensitive components? | Yes. 316L and 304L stainless steel are non-magnetic and widely used for OIS/AF systems. |

| How small can MIM parts be? | Features down to 0.2 mm and parts under 0.5 g are possible with fine powders. |

| What is the tolerances range? | ±0.3% of dimension, with typical ±0.03 mm. |

| Is MIM cost-effective? | Extremely cost-effective for mass production above 50k–100k units. |

Conclusion

Metal Injection Molding has evolved into a transformative technology that enables the miniaturisation, integration, and performance improvements required in modern consumer electronics. Its ability to mass-produce micro-complex, high-strength metal parts positions it as a foundational manufacturing technique for smartphones, wearables, laptops, and next-generation compact devices. With advancements in fine powder metallurgy, automation, and AI-driven sintering control, MIM will continue reshaping how electronic devices are designed and manufactured—unlocking new levels of functionality, precision, and structural innovation.

Looking for high-quality powder product? Contact us today!