CuZn40 Powder 2025: Properties, Applications, and Top Suppliers

Overview of CuZn40 Powder

CuZn40 powder, also known as 40% Zinc Brass Powder, is a copper-zinc alloy widely used in additive manufacturing, metal injection molding (MIM), thermal spraying, and sintering applications. This brass alloy offers excellent corrosion resistance, good mechanical properties, and superior thermal and electrical conductivity.

The 40% zinc content in CuZn40 provides increased strength and hardness compared to lower-zinc brass alloys while maintaining good machinability and wear resistance. It is commonly used in automotive, marine, electronics, and decorative applications.

In this guide, we’ll explore the best CuZn40 powder for 3D printing, its properties, applications, production methods, and top suppliers in 2025.

Best CuZn40 Powder for 3D Printing

Brass alloys like CuZn40 are gaining popularity in additive manufacturing due to their good printability, wear resistance, and aesthetic appeal.

Why Choose CuZn40 for 3D Printing?

- Excellent Corrosion Resistance – Performs well in marine and industrial environments.

- Good Thermal & Electrical Conductivity – Ideal for electronic components and heat exchangers.

- Superior Machinability – Easier to work with compared to pure copper.

- High Strength & Hardness – Offers better wear resistance than low-zinc brass alloys.

- Attractive Finish – Brass parts have a golden appearance, making them suitable for decorative applications.

Comparison of CuZn40 vs. Other Metal Powders for 3D Printing

| Property | CuZn40 | Pure Copper | Bronze (CuSn) | Stainless Steel 316L | AlSi10Mg |

|---|---|---|---|---|---|

| Density (g/cm³) | 8.2 | 8.96 | 8.8 | 7.99 | 2.7 |

| Tensile Strength (MPa) | 300-400 | 210-250 | 250-350 | 485-620 | 320-450 |

| Corrosion Resistance | High | Excellent | Very High | Excellent | High |

| Electrical Conductivity (% IACS) | 28-32 | 100 | 15-20 | Low | Low |

| Cost ($/kg) | $$$ | $$$$ | $$$ | $$$ | $$ |

CuZn40 offers an excellent balance of strength, corrosion resistance, and electrical conductivity, making it ideal for functional and decorative applications in 3D printing.

How to Choose the Right CuZn40 Powder

Selecting the best CuZn40 powder depends on particle size, purity, and production method.

Key Factors in Choosing CuZn40 Powder

- Particle Size Distribution – Common sizes: 15-45µm (LPBF, SLM), 45-75µm (Binder Jetting, DED).

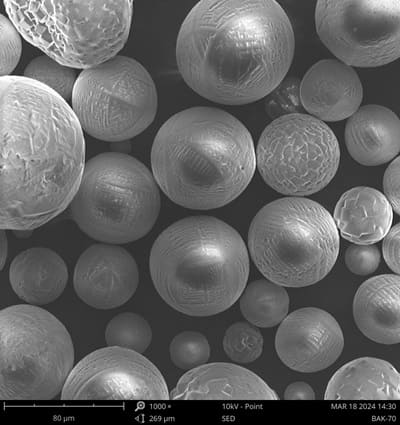

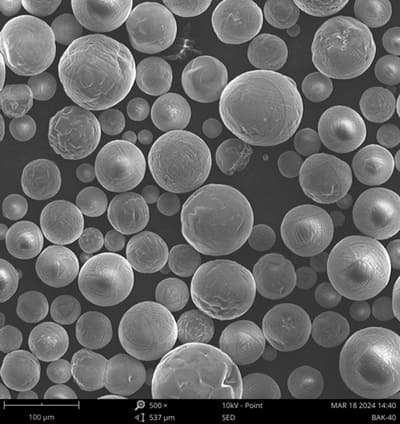

- Sphericity – Spherical powders ensure better flowability, higher density, and fewer printing defects.

- Purity – Low oxygen and sulfur content improves mechanical performance.

- Production Method – Gas atomization and water atomization produce high-quality powder.

- Application Compatibility – Ensure the powder is optimized for your specific 3D printing or manufacturing process.

Why Choose Heeger Materials Inc. for CuZn40 Powder?

Heeger Materials Inc. is a trusted supplier of high-quality CuZn40 powder, utilizing Vacuum Induction Gas Atomization (VIGA) and water atomization to achieve high purity, excellent flowability, and uniform particle size distribution.

If you need premium CuZn40 powder, Heeger Materials is an excellent choice.

Top CuZn40 Powder Suppliers in 2025

Finding a reliable supplier is crucial for consistent quality and performance in 3D printing, thermal spraying, and sintering applications.

Leading CuZn40 Powder Suppliers

| Supplier Name | Country | Specialization | Production Methods | Website |

|---|---|---|---|---|

| Heeger Materials Inc. | USA | 3D Printing Powders | VIGA, Water Atomization | Visit Site |

| Höganäs | Sweden | Metal Powders | Water Atomization | N/A |

| Oerlikon Metco | Switzerland | Thermal Spray Powders | Gas Atomization | N/A |

| Sandvik | Sweden | Additive Manufacturing | Gas Atomization | N/A |

Why Heeger Materials?

- 40+ years of expertise in powder metallurgy.

- Advanced atomization processes ensuring high-quality spherical powders.

- Strong collaborations with universities, research institutes, and industrial partners.

- Competitive pricing and global distribution.

Looking for premium CuZn40 powder? Contact us today!

Quality Standards

To ensure high performance and reliability, CuZn40 powder must meet strict industrial and manufacturing standards. High-quality powder ensures better printability, mechanical strength, and long-term durability.

Key Quality Standards

| Standard | Description |

|---|---|

| ASTM B134 | Standard specification for brass powder metallurgy materials. |

| ISO 9001 | Certification for quality management systems ensuring consistency. |

| ASTM B42 | Specification for copper-zinc alloys used in high-performance applications. |

| AMS 4880 | Aerospace Material Specification for brass alloys. |

| RoHS Compliance | Ensures environmental safety by limiting hazardous substances. |

Why Buy Certified CuZn40 Powder?

- Consistent Particle Size & Shape – Essential for uniform sintering and additive manufacturing.

- Improved Mechanical Properties – Meets strength, hardness, and wear resistance requirements.

- Minimized Contaminants – Low oxygen, sulfur, and lead content ensures high purity.

- Compliance with Industrial Standards – Essential for automotive, marine, and aerospace applications.

At Heeger Materials Inc., we manufacture high-quality CuZn40 powder that meets ASTM, AMS, and ISO standards, ensuring optimal performance and reliability.

Cost Analysis

The price of CuZn40 powder is influenced by several factors, including production method, purity, and demand.

Factors Affecting CuZn40 Powder Cost

- Production Method – Gas atomization (GA) and water atomization (WA) impact cost and quality.

- Particle Size Distribution – Fine powders (15-45µm) for LPBF are more expensive due to higher processing precision.

- Purity Levels – Lower oxygen and sulfur content increases cost but improves mechanical performance.

- Supply & Demand – Prices fluctuate based on global market demand and raw material costs.

Price Comparison of CuZn40 vs. Other Metal Powders

| Powder Type | Cost ($/kg) | Common Use Case |

|---|---|---|

| CuZn40 Brass Powder | 50−50 – 50−150 | Automotive, marine, electronics, decorative applications |

| Pure Copper Powder | 100−100 – 100−300 | Electrical components, conductive coatings |

| Bronze (CuSn) Powder | 80−80 – 80−200 | Bearings, bushings, gears |

| Stainless Steel 316L | 80−80 – 80−150 | General engineering, medical applications |

| AlSi10Mg Powder | 50−50 – 50−120 | Automotive, industrial 3D printing |

While CuZn40 is more affordable than pure copper, it offers higher strength and better machinability, making it a cost-effective choice for functional and decorative applications.

Request a price quote for bulk orders of CuZn40 powder.

Particle Size and Shape

The particle size and morphology of CuZn40 powder play a crucial role in flowability, density, and final part properties.

Why Particle Size Matters

- Fine Powder (15-45 µm) – Best for laser powder bed fusion (LPBF) and selective laser melting (SLM).

- Medium Powder (45-75 µm) – Used in binder jetting and direct energy deposition (DED).

- Coarse Powder (75-150 µm) – Suitable for metal injection molding (MIM) and cold spray.

Spherical vs. Irregular Powder: Which is Better?

| Powder Shape | Characteristics | Best Application |

|---|---|---|

| Spherical | Excellent flowability, uniform packing, low porosity | 3D printing, SLM, LPBF |

| Irregular | Lower flowability, higher porosity, cheaper production | MIM, Binder Jetting |

Gas-atomized spherical CuZn40 powder is preferred for 3D printing due to its superior flowability, density, and reduced defects.

Explore our high-quality spherical brass alloy powders.

Production Methods

Different powder production methods influence particle shape, purity, and cost.

Comparison of Production Methods

| Production Method | Particle Shape | Purity | Cost | Best Use Case |

|---|---|---|---|---|

| Gas Atomization (GA) | Spherical | High | $$$ | 3D Printing, Aerospace |

| Water Atomization (WA) | Irregular | Medium | $$ | MIM, Binder Jetting |

| Electrolytic Process | Flake-Like | Very High | $$$$ | Specialized Coatings |

Gas atomization is the most widely used method for CuZn40 powder, ensuring excellent sphericity, low oxygen content, and high purity.

Heeger Materials Inc. specializes in gas-atomized and water-atomized CuZn40 powder, providing superior quality and consistency.

FAQ

| Question | Answer |

|---|---|

| What is CuZn40 powder used for? | It is used in additive manufacturing, thermal spraying, metal injection molding, and sintering for corrosion-resistant and conductive components. |

| Why is CuZn40 preferred for 3D printing? | It offers good strength, corrosion resistance, and electrical conductivity, making it ideal for functional and decorative applications. |

| What is the difference between CuZn40 and pure copper? | CuZn40 has higher strength and hardness, while pure copper has better electrical conductivity. |

| What is the typical particle size for CuZn40 powder? | 15-45µm for LPBF, 45-75µm for binder jetting & DED. |

| Where can I buy high-quality CuZn40 powder? | Heeger Materials Inc. provides premium CuZn40 powder for industrial applications. |

Conclusion

CuZn40 powder is a high-performance brass alloy with excellent corrosion resistance, electrical conductivity, and mechanical strength. It is widely used in 3D printing, thermal spraying, and sintering applications.

For top-quality CuZn40 powder, Heeger Materials Inc. offers high-purity, spherical powders produced using advanced atomization techniques.

Looking for premium CuZn40 powder? Contact us today!