Polvo de aleación de cobalto 2025: Propiedades, aplicaciones y perspectivas de mercado

Visión general

Polvo de aleación de cobalto es un material de alto rendimiento conocido por su excepcional resistencia al desgaste, resistencia a la corrosión, estabilidad a altas temperaturas y biocompatibilidad. Debido a estas propiedades, las aleaciones de cobalto desempeñan un papel crucial en aeroespacial, implantes médicos, energía y fabricación aditiva (Impresión 3D).

Aleaciones a base de cobalto, como CoCrMo, CoCrW y estelitase utilizan ampliamente en superaleaciones, herramientas de corte, componentes de turbinas e implantes ortopédicos. Su alta resistencia mecánica y a la oxidación hacer de ellos un material esencial para entornos extremos.

En Heeger Materials Inc.Estamos especializados en polvos de aleación de cobalto de gran purezagarantizando rendimiento óptimo para aplicaciones industriales y científicas.

¿Por qué elegir polvo de aleación de cobalto?

Los polvos de aleación de cobalto son los preferidos para aplicaciones industriales exigentes debido a su combinación única de resistencia, durabilidad y biocompatibilidad.

Principales ventajas

- Resistencia superior al desgaste y la corrosión - Ideal para entornos difíciles, como la industria química y marina.

- Resistencia a altas temperaturas - Mantiene integridad estructural en condiciones de calor extremopor lo que es perfecto para aplicaciones aeroespaciales y energéticas.

- Excelente biocompatibilidad - Adecuado para implantes médicos e instrumental quirúrgico.

- Propiedades mecánicas mejoradas - Mejora dureza, tenacidad y resistencia a la fatiga en componentes industriales.

- Óptimo para la fabricación aditiva - Muy utilizado en Impresión 3D para geometrías complejas y piezas de alto rendimiento.

En busca de ¿polvo de aleación de cobalto de primera calidad? Explore la selección de Heeger Materials.

Las mejores calidades de polvo de aleación de cobalto para distintas aplicaciones

Los polvos de aleación de cobalto se clasifican en función de composición, propiedades mecánicas y aplicaciones previstas.

Comparación

| Composición de la aleación | Propiedades clave | Mejores aplicaciones |

|---|---|---|

| CoCrMo (Cobalto-Cromo-Molibdeno) | Alta resistencia al desgaste, biocompatibilidad | Implantes médicos, dispositivos ortopédicos |

| CoCrW (Cobalto-Cromo-Tungsteno) | Excelente resistencia a altas temperaturas | Aeroespacial, componentes de turbinas |

| Aleaciones de estelita (Co-Cr-W-Mo) | Mayor resistencia al desgaste y a la corrosión | Herramientas de corte, asientos de válvulas, revestimientos |

| CoNiCrAlY (cobalto-níquel-cromo-aluminio-itrio) | Resistencia a la oxidación, estabilidad térmica | Revestimientos de barrera térmica, motores a reacción |

| Co-WC (carburo de cobalto-tungsteno) | Dureza extrema, excelente resistencia al desgaste | Herramientas de corte, brocas, revestimientos industriales |

Aleaciones de CoCrMo se prefieren para aplicaciones médicasmientras que Stellite y aleaciones CoNiCrAlY son esenciales para componentes aeroespaciales de alta temperatura.

Solicite un presupuesto personalizado para polvos de aleaciones de cobalto.

Productos relacionados

-

Polvo esférico de aleación con base de cobalto - Polvo de aleación con base de cobalto - Fabricación aditiva - Impresión 3D

-

Polvo esférico de aleación de CoCrMo y cobalto - Polvo de aleación de CoCrMo - Fabricación aditiva - Impresión 3D

-

Polvo esférico de aleación con base de cobalto CoCrMoNi - Polvo de aleación CoCrMoNi - Fabricación aditiva - Impresión 3D

-

Polvo esférico de aleación de cobalto CoCrMoW - Polvo de aleación CoCrMoW - Fabricación aditiva - Impresión 3D

Aplicaciones

Los polvos de aleación de cobalto se utilizan en aplicaciones de alto rendimiento que requiere extrema durabilidad, resistencia al calor y al desgaste.

Aplicaciones industriales clave

| Industria | Aplicación | Ventajas |

|---|---|---|

| Aeroespacial y defensa | Álabes de turbina, componentes de motores a reacción | Resistencia a altas temperaturas, estabilidad a la oxidación |

| Medicina y sanidad | Implantes de cadera, prótesis de rodilla, prótesis dentales | Biocompatibilidad, resistencia a la corrosión |

| Energía y generación de electricidad | Turbinas de gas, componentes de reactores nucleares | Excelente resistencia a altas temperaturas |

| Fabricación aditiva (AM) | Piezas industriales y médicas impresas en 3D | Alta precisión, geometrías complejas |

| Revestimientos resistentes al desgaste | Recubrimientos duros, herramientas de corte | Dureza superior, mayor vida útil |

Con el creciente demanda de materiales de alto rendimiento, polvos de aleación de cobalto se están convirtiendo en indispensables en industrias críticas.

Descubra nuestros polvos de aleación de cobalto de gran pureza.

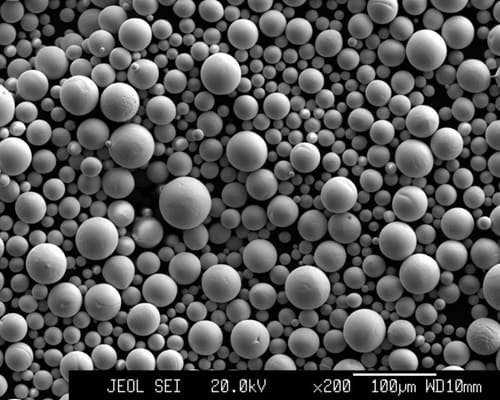

Tamaño y forma de las partículas

En distribución del tamaño de las partículas (PSD) y morfología impacto fluidez, comportamiento de sinterización y calidad del producto final en Impresión 3D, revestimientos y aplicaciones estructurales.

Tamaño óptimo de las partículas

| Gama de tamaños de partículas | Mejor aplicación |

|---|---|

| 0,5-10 µm | Recubrimientos de alto rendimiento, aplicaciones catalizadoras |

| 10-45 µm | Implantes biomédicos, revestimientos resistentes al desgaste |

| 45-150 µm | Impresión 3D, componentes aeroespaciales |

Polvo de aleación de cobalto esférico frente a irregular: ¿cuál es mejor?

| Forma de polvo | Características | Mejor aplicación |

|---|---|---|

| Esférica | Alta fluidez, empaquetado uniforme, sinterización mejorada | Impresión 3D, aeroespacial, aplicaciones médicas |

| Irregular | Mayor superficie, mayor porosidad | Revestimientos resistentes al desgaste, tratamiento químico |

Polvos esféricos de aleación de cobalto se prefieren para fabricación aditivamientras que polvos irregulares se utilizan en revestimientos y procesos químicos.

Explore nuestros polvos de aleación de cobalto optimizados.

Normas de calidad

Para garantizar coherencia, rendimiento y seguridad, los polvos de aleación de cobalto deben cumplir estrictas normas internacionales que rige pureza, composición, distribución granulométrica y propiedades mecánicas. Estas normas son esenciales para aplicaciones aeroespaciales, médicas y energéticas.

Principales normas de calidad

| Estándar | Descripción |

|---|---|

| ASTM F75 | Especificación para aleaciones de cobalto-cromo-molibdeno (CoCrMo) utilizadas en implantes médicos. |

| ASTM F1537 | Norma para aleaciones a base de cobalto utilizadas en dispositivos ortopédicos. |

| ISO 5832-4 | Norma internacional para implantes quirúrgicos a base de cobalto. |

| AMS 5894 | Especificación de materiales aeroespaciales para aleaciones de cobalto utilizadas en motores a reacción. |

| ASTM B214 | Define análisis granulométrico de polvos metálicos. |

| Conformidad con RoHS y REACH | Garantiza seguridad medioambiental mediante la restricción de sustancias peligrosas. |

¿Por qué elegir polvo de aleación de cobalto certificado?

- Garantiza una pureza y un rendimiento óptimos - Garantías alta resistencia mecánica y a la corrosión.

- Crítico para uso aeroespacial y médico - Reuniones estrictas normas industriales de seguridad y durabilidad.

- Optimizado para la fabricación aditiva - Garantiza fluidez e imprimibilidad uniformes del polvo.

- Cumplimiento global - Se adhiere a normas internacionales para aplicaciones de alta tecnología.

En Heeger Materials Inc.ofrecemos polvos de aleación de cobalto de gran pureza que cumplan Normas ASTM, ISO y AMSgarantizando rendimiento y fiabilidad superiores.

Análisis de costes

El precio de polvo de aleación de cobalto depende de varios factores, entre ellos coste de la materia prima, método de producción, tamaño de las partículas y demanda de la industria. Como el cobalto es un material estratégico con suministro fluctuanteLos precios pueden variar considerablemente.

Factores que afectan al coste del polvo de aleación de cobalto

- Composición elemental - Las aleaciones que contienen wolframio, molibdeno o níquel suelen ser más caras..

- Método de producción - La atomización con gas y la atomización con plasma aumentan el coste en comparación con el fresado mecánico.

- Distribución del tamaño de las partículas (PSD) - Los tamaños de partícula más pequeños (5-50 µm) para aplicaciones médicas y de impresión 3D requieren un procesamiento avanzado, lo que eleva los costes..

- Demanda del mercado y cadena de suministro - Los precios fluctúan en función de demandas de los sectores aeroespacial, médico y manufacturero.

Comparación de precios

| Tipo de aleación de cobalto | Coste ($/kg) | Caso de uso común |

|---|---|---|

| CoCrMo (aleación de cobalto de calidad médica) | 300-300 - 300-1,200 | Implantes ortopédicos, prótesis dentales |

| CoCrW (aleación de cobalto de calidad aeroespacial) | 500-500 - 500-1,500 | Motores a reacción, álabes de turbina |

| Stellite (aleación de cobalto resistente al desgaste) | 400-400 - 400-1,300 | Herramientas de corte, asientos de válvulas, revestimientos |

| CoNiCrAlY (aleación de revestimiento de barrera térmica) | 600-600 - 600-2,000 | Aeroespacial, revestimientos de turbinas de gas |

| Co-WC (aleación de cobalto y carburo de tungsteno) | 700-700 - 700-2,500 | Herramientas de corte, revestimientos antidesgaste |

Aleaciones de CoCrMo se utilizan ampliamente en implantes médicosmientras que Aleaciones CoCrW y CoNiCrAlY domina aplicaciones aeroespaciales y turbinas.

Solicite un presupuesto de precios al por mayor de polvos de aleación de cobalto.

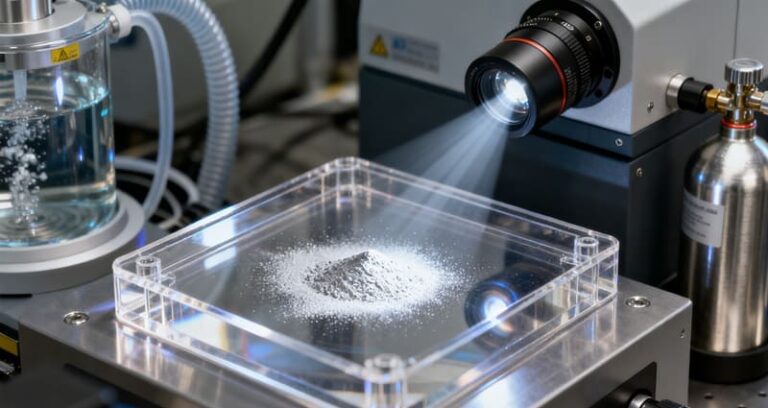

Métodos de producción

Diferentes técnicas de producción de polvo impacto morfología, pureza y coste de las partículaspor lo que es esencial seleccionar el método adecuado para la aplicación prevista.

Comparación

| Método de producción | Forma de las partículas | Pureza | Coste | El mejor caso de uso |

|---|---|---|---|---|

| Fresado mecánico | Irregular | Moderado | $$ | Recubrimientos resistentes al desgaste, aplicaciones de sinterización |

| Atomización de gas (GA) | Esférica | Alta | $$$ | Impresión 3D, piezas aeroespaciales |

| Atomización por plasma (PA) | Altamente esférico | Ultra Alta | $$$$ | Aplicaciones médicas, AM de alta precisión |

| Fusión por inducción en vacío (VIM) | Dendrítico o esférico | Muy alta | $$$ | Superaleaciones, aplicaciones aeroespaciales |

Polvos de aleaciones de cobalto atomizados con gas y tratados con plasma se prefieren para aplicaciones de alto rendimientogarantizando fluidez e imprimibilidad superiores.

Heeger Materials Inc. se especializa en polvos de aleación de cobalto de gran pureza atomizados por gas para aplicaciones industriales de vanguardia.

PREGUNTAS FRECUENTES

| Pregunta | Respuesta |

|---|---|

| ¿Para qué se utiliza el polvo de aleación de cobalto? | Se utiliza en implantes médicos, componentes aeroespaciales, herramientas de corte, revestimientos e impresión 3D. |

| ¿Por qué se utilizan aleaciones de cobalto en los implantes médicos? | Las aleaciones de cobalto ofrecen excelente biocompatibilidad, resistencia al desgaste y a la corrosiónpor lo que son ideales para prótesis de cadera y rodilla. |

| ¿Qué aleación de cobalto es la mejor para aplicaciones aeroespaciales? | Aleaciones CoCrW y CoNiCrAlY proporcionar resistencia a la oxidación a altas temperaturaspor lo que son adecuados para componentes de motores a reacción. |

| ¿Cómo se compara la aleación de cobalto con el titanio para implantes médicos? | Las aleaciones de cobalto son más duras y resistentes al desgaste que el titanio.de la UE, haciéndolos mejores para implantes de carga. |

| ¿Dónde puedo comprar polvo de aleación de cobalto de gran pureza? | Heeger Materials Inc. proporciona polvos de aleaciones de cobalto para aplicaciones industriales. |

Conclusión

Polvo de aleación de cobalto es un material crítico para las industrias de alta tecnología, ofreciendo excepcional resistencia al desgaste, estabilidad a altas temperaturas y biocompatibilidad para aplicaciones aeroespaciales, médicas, energéticas y de fabricación aditiva.

Para polvos de aleación de cobalto de primera calidad, Heeger Materials Inc. proporciona soluciones a medida con polvos esféricos atomizados por gas de gran pureza.

¿Busca polvo de aleación de cobalto de primera calidad? Póngase en contacto con nosotros