Polvo de aleación de alta entropía 2025: Propiedades, aplicaciones y perspectivas de mercado

Polvo de aleación de alta entropía

Polvo de aleación de alta entropía (HEA) es un material de vanguardia compuesto por múltiples elementos principales en proporciones atómicas casi igualeslo que resulta en excepcional resistencia mecánica, estabilidad térmica y resistencia a la corrosión. A diferencia de las aleaciones tradicionales, que dependen de un único elemento dominante, las HEA aprovechan el sinergia de múltiples metales para conseguir propiedades superiores.

Debido a su gran dureza, excelente resistencia a la oxidación y extraordinaria resistencia al desgaste, polvos de aleación de alta entropía se utilizan ampliamente en aeroespacial, defensa, biomédica, energía y fabricación aditiva (impresión 3D).

En Heeger Materials Inc.proporcionamos polvos de aleación de alta pureza y alta entropía atomizados por gasgarantizando rendimiento óptimo para aplicaciones industriales avanzadas.

¿Por qué elegir el polvo de aleación de alta entropía?

Las aleaciones de alta entropía son revolucionando la ciencia de los materiales ofreciendo resistencia, estabilidad y versatilidad inigualables para aplicaciones extremas.

Principales ventajas del polvo de aleación de alta entropía

- Resistencia mecánica superior - Exposición HEAs gran dureza, resistencia al desgaste y tenacidadsuperando a las aleaciones convencionales.

- Excelente estabilidad térmica - Mantiene integridad estructural a temperaturas extremaspor lo que es ideal para aplicaciones aeroespaciales y energéticas.

- Excepcional resistencia a la corrosión y la oxidación - Adecuado para entornos difíciles, incluidas las industrias marina y química.

- Composición a medida - Permite personalización de propiedades en función de las necesidades de la aplicación.

- Mayor rendimiento para la fabricación aditiva - Los HEA se utilizan ampliamente en Impresión 3D y tecnologías avanzadas de fabricación.

En busca de ¿Polvo HEA de alto rendimiento? Explore la selección de Heeger Materials.

Las mejores composiciones de polvo de aleación de alta entropía para distintas aplicaciones

Los polvos HEA se clasifican en función de composición elemental, aplicación y método de transformación.

Comparación de polvos comunes de aleaciones de alta entropía

| Composición de la aleación | Propiedades clave | Mejores aplicaciones |

|---|---|---|

| CoCrFeNiMn | Alta resistencia, resistencia a la corrosión | Aeroespacial, marina, biomédica |

| AlCoCrFeNi | Estabilidad a altas temperaturas, resistencia a la oxidación | Álabes de turbina, intercambiadores de calor |

| MoNbTaW | Resistencia a temperaturas ultra altas, dureza | Aeroespacial, reactores nucleares |

| TiVZrNbHf | Ligereza, alta ductilidad, biocompatibilidad | Implantes médicos, materiales estructurales |

| NiCrCoFeMo | Resistencia al desgaste, excelente resistencia mecánica | Herramientas de corte, revestimientos |

MoNbTaW HEAs se prefieren para aplicaciones de alta temperaturamientras que TiVZrNbHf HEAs se utilizan ampliamente en aplicaciones biomédicas y estructurales.

Solicite un presupuesto personalizado de HEA en polvo.

Productos relacionados

-

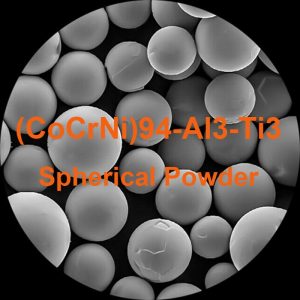

Polvo esférico de aleación de alta entropía (CoCrNi)94-Al3-Ti3 - (CoCrNi)94-Al3-Ti3 HEA - Fabricación aditiva - Impresión 3D

-

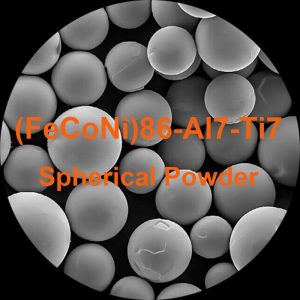

Polvo esférico de aleación de alta entropía (FeCoNi)86-Al7-Ti7 - (FeCoNi)86-Al7-Ti7 HEA - Fabricación aditiva - Impresión 3D

-

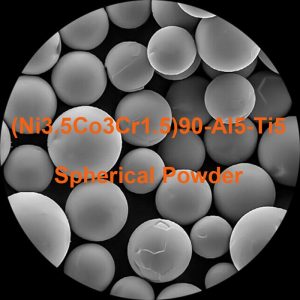

(Ni3.5Co3Cr1.5)90-Al5-Ti5 Polvo esférico de aleación de alta entropía - (Ni3.5Co3Cr1.5)90-Al5-Ti5 HEA - Fabricación aditiva - Impresión 3D

-

Polvo esférico de aleación de alta entropía Al-Co-Cr-Fe-Mo - Al-Co-Cr-Fe-Mo HEA - Fabricación aditiva - Impresión 3D

Aplicaciones del polvo de aleación de alta entropía en la industria

Los polvos de HEA se utilizan en aplicaciones de alto rendimiento que requieren durabilidad extrema, estabilidad térmica y propiedades mecánicas superiores.

Principales aplicaciones industriales del polvo de HEA

| Industria | Aplicación | Ventajas |

|---|---|---|

| Aeroespacial y defensa | Componentes de motores a reacción, escudos térmicos | Elevada relación resistencia/peso, resistencia a temperaturas extremas |

| Biomedicina y sanidad | Implantes quirúrgicos, prótesis | Biocompatibilidad, resistencia a la corrosión |

| Energía y energía nuclear | Componentes de reactores nucleares, materiales de fusión | Resistencia a la radiación, estabilidad térmica |

| Fabricación aditiva (AM) | Piezas de alto rendimiento impresas en 3D | Alta precisión, geometrías complejas |

| Revestimientos resistentes al desgaste | Recubrimientos duros, herramientas de corte | Dureza superior, mayor vida útil |

Con el creciente demanda de materiales de alta resistencia a la corrosión, polvos de aleación de alta entropía se están convirtiendo rápidamente en cambio de juego en las industrias avanzadas.

Descubra nuestros polvos de HEA de gran pureza.

Tamaño y forma de las partículas en el polvo de aleaciones de alta entropía

En distribución del tamaño de las partículas (PSD) y morfología impacto fluidez, comportamiento de sinterización y calidad del producto final en Impresión 3D, revestimientos y aplicaciones estructurales.

Tamaño óptimo de las partículas para aplicaciones de HEA en polvo

| Gama de tamaños de partículas | Mejor aplicación |

|---|---|

| 0,5-10 µm | Recubrimientos de alto rendimiento, aplicaciones catalizadoras |

| 10-45 µm | Implantes biomédicos, electrónica avanzada |

| 45-150 µm | Impresión 3D, componentes aeroespaciales |

Polvo de aleación de alta entropía esférico frente a irregular: ¿cuál es mejor?

| Forma de polvo | Características | Mejor aplicación |

|---|---|---|

| Esférica | Alta fluidez, empaquetado uniforme, sinterización mejorada | Impresión 3D, aeroespacial, aplicaciones médicas |

| Irregular | Mayor superficie, mayor porosidad | Revestimientos, tratamiento químico, materiales resistentes al desgaste |

Polvos esféricos de HEA se prefieren para fabricación aditivamientras que polvos irregulares se utilizan en revestimientos y procesos químicos.

Explore nuestros polvos HEA optimizados.

Normas de calidad para el polvo de aleación de alta entropía

Para garantizar fiabilidad, coherencia y rendimiento superiorLos polvos de aleación de alta entropía (HEA) deben cumplir los siguientes requisitos normas internacionales estrictas regulando su pureza, composición, microestructura y propiedades mecánicas. Estas normas son fundamentales para las aplicaciones en aeroespacial, médica, defensa y fabricación aditiva (AM).

Principales normas de calidad para el polvo de aleación de alta entropía

| Estándar | Descripción |

|---|---|

| ASTM F3318 | Especificación para polvos metálicos, incluidos los HEA, utilizados en la fabricación aditiva. |

| ASTM B214 | Norma para análisis granulométrico de polvos metálicos. |

| ISO 22068 | Norma internacional para HEA utilizados en aplicaciones de alta temperatura. |

| AMS 4999 | Especificación de materiales aeroespaciales para aleaciones de alta entropía en motores de turbina. |

| Conformidad con RoHS y REACH | Garantiza seguridad medioambiental y restricción de sustancias peligrosas. |

¿Por qué elegir el polvo certificado de aleación de alta entropía?

- Garantiza una pureza y un rendimiento óptimos - Garantías alta estabilidad térmica y resistencia mecánica.

- Esencial para uso aeroespacial y médico - Reuniones normas estrictas para entornos de alto rendimiento.

- Optimizado para la fabricación aditiva - Garantiza fluidez e imprimibilidad uniformes del polvo.

- Cumplimiento global - Se adhiere a normas internacionales para aplicaciones de materiales avanzados.

En Heeger Materials Inc., nuestro polvos de HEA de gran pureza cumplir Normas ASTM, ISO y AMSgarantizando calidad y fiabilidad excepcionales.

Análisis de costes de la aleación de alta entropía en polvo

El precio de polvo de aleación de alta entropía depende de varios factores, entre ellos composición de los elementos, método de producción, tamaño de las partículas y demanda del mercado. Dado que las HEA incorporan múltiples metales de alto rendimientosuelen ser más caras que las aleaciones tradicionales.

Factores que influyen en el coste del polvo de aleación de alta entropía

- Composición elemental - Los HEA que contienen elementos raros como el hafnio, el renio y el tantalio son mucho más caros..

- Método de producción - La atomización con gas y la atomización con plasma aumentan el coste en comparación con el fresado mecánico.

- Distribución del tamaño de las partículas (PSD) - Los polvos más finos (5-50 µm) para impresión 3D requieren un procesamiento avanzado, lo que eleva los costes.

- Demanda del mercado y tendencias del sector - Los precios fluctúan debido a uso creciente en las industrias aeroespacial, energética y biomédica.

Comparación de precios de polvos de aleaciones de alta entropía

| Tipo de aleación de alta entropía | Coste ($/kg) | Caso de uso común |

|---|---|---|

| CoCrFeNiMn HEA Polvo | 200-200 - 200-800 | Revestimientos aeroespaciales resistentes a la corrosión |

| AlCoCrFeNi HEA Polvo | 500-500 - 500-1,500 | Álabes de turbina, intercambiadores de calor |

| MoNbTaW HEA Polvo | 1,500-1,500 - 1,500-4,000 | Aplicaciones nucleares y de temperaturas extremas |

| TiVZrNbHf HEA Polvo | 1,000-1,000 - 1,000-3,000 | Materiales biomédicos y estructurales |

| NiCrCoFeMo HEA Polvo | 700-700 - 700-2,500 | Recubrimientos antidesgaste, herramientas de corte |

MoNbTaW HEAs domina aplicaciones de alta temperaturamientras que CoCrFeNiMn HEAs se utilizan ampliamente en aplicaciones marinas y aeroespaciales.

Solicite un presupuesto de precios al por mayor de HEA en polvo.

Métodos de producción de aleaciones de alta entropía en polvo

Diferentes técnicas de producción de polvo impacto morfología, pureza y coste de las partículaspor lo que es esencial seleccionar el método adecuado para la aplicación prevista.

Comparación de métodos de producción de polvo de aleaciones de alta entropía

| Método de producción | Forma de las partículas | Pureza | Coste | El mejor caso de uso |

|---|---|---|---|---|

| Aleación mecánica (MA) | Irregular | Moderado | $$ | Recubrimientos resistentes al desgaste, aplicaciones de sinterización |

| Atomización de gas (GA) | Esférica | Alta | $$$ | Impresión 3D, piezas aeroespaciales |

| Atomización por plasma (PA) | Altamente esférico | Ultra Alta | $$$$ | Aplicaciones médicas, AM de alta precisión |

| Fusión por inducción en vacío (VIM) | Dendrítico o esférico | Muy alta | $$$ | Superaleaciones, aplicaciones aeroespaciales |

Polvos de HEA atomizados con gas y procesados con plasma se prefieren para fabricación aditiva y sector aeroespacialgarantizando fluidez e imprimibilidad superiores.

Heeger Materials Inc. se especializa en polvos de aleación de alta entropía atomizados por gas de gran pureza para aplicaciones industriales de vanguardia.

Preguntas frecuentes sobre el polvo de aleación de alta entropía

| Pregunta | Respuesta |

|---|---|

| ¿Para qué se utiliza el polvo de aleación de alta entropía? | Los HEA se utilizan en aeroespacial, energía, implantes médicos, revestimientos e impresión 3D. |

| ¿Por qué las aleaciones de alta entropía son mejores que las aleaciones tradicionales? | Los HEA ofrecen mayor resistencia, mejor estabilidad térmica y mayor resistencia a la corrosión debido a su composición multielemental. |

| ¿Qué composición de HEA es la mejor para aplicaciones aeroespaciales? | HEAs de AlCoCrFeNi y MoNbTaW proporcionar estabilidad a altas temperaturas y resistencia a la oxidaciónpor lo que son ideales para motores a reacción y álabes de turbina. |

| ¿Cómo se compara el polvo de HEA con las aleaciones de titanio? | Los HEA pueden ser más fuerte, más resistente a la corrosión y más estable térmicamente que las aleaciones de titanio, según la composición. |

| ¿Dónde puedo comprar HEA en polvo de gran pureza? | Heeger Materials Inc. proporciona Polvos de HEA para aplicaciones industriales. |

Conclusión

Polvo de aleación de alta entropía está revolucionando la ciencia de los materiales al ofrecer resistencia mecánica, resistencia a la corrosión y estabilidad térmica superiores para aplicaciones aeroespaciales, médicas, energéticas y de fabricación aditiva.

Para polvos HEA de alta calidad, Heeger Materials Inc. proporciona soluciones a medida con polvos esféricos atomizados por gas de gran pureza.

¿Busca polvo de aleación de alta entropía? Póngase en contacto con nosotros