Niobio en polvo 2025: Propiedades, aplicaciones y perspectivas de mercado

Visión general del niobio en polvo

Niobio en polvo es un metal refractario de alto rendimiento conocido por su excelente resistencia a la corrosión, propiedades superconductoras, alto punto de fusión (2.477°C) y biocompatibilidad. Se utiliza ampliamente en aeroespacial, implantes médicos, superconductores y fabricación aditiva (impresión 3D).

Debido a su resistencia, ligereza y capacidad para mejorar el rendimiento de las aleaciones, polvo de niobio es un material clave en superaleaciones, condensadores, revestimientos y electrónica avanzada.

En Heeger Materials Inc.Estamos especializados en polvos de niobio de gran purezagarantizando rendimiento superior para aplicaciones industriales y científicas.

¿Por qué elegir polvo de niobio?

El polvo de niobio es un material esencial en las industrias de alto rendimiento debido a su propiedades químicas y mecánicas únicas.

Principales ventajas del niobio en polvo

- Excepcional resistencia a la corrosión - Muy resistente a ácidos y ambientes agresivos.

- Propiedades superconductoras - Utilizado en imanes superconductores, máquinas de resonancia magnética y aceleradores de partículas..

- Alto punto de fusión (2.477°C) - Adecuado para aplicaciones aeroespaciales e industriales a temperaturas extremas.

- Biocompatibilidad - Ideal para implantes médicos e instrumental quirúrgico.

- Mejora la resistencia de la aleación - Mejora propiedades mecánicas del acero y las superaleaciones.

En busca de ¿polvo de niobio de alto rendimiento? Explore la selección de Heeger Materials.

Las mejores calidades de polvo de niobio para distintas aplicaciones

Los polvos de niobio se clasifican en función de pureza, tamaño de las partículas y aplicaciones previstas.

Comparación de las calidades del polvo de niobio

| Grado | Pureza (%) | Propiedades clave | Mejores aplicaciones |

|---|---|---|---|

| Niobio en polvo para condensadores | 99.9+% | Alta superficie, excelente conductividad | Condensadores, componentes electrónicos |

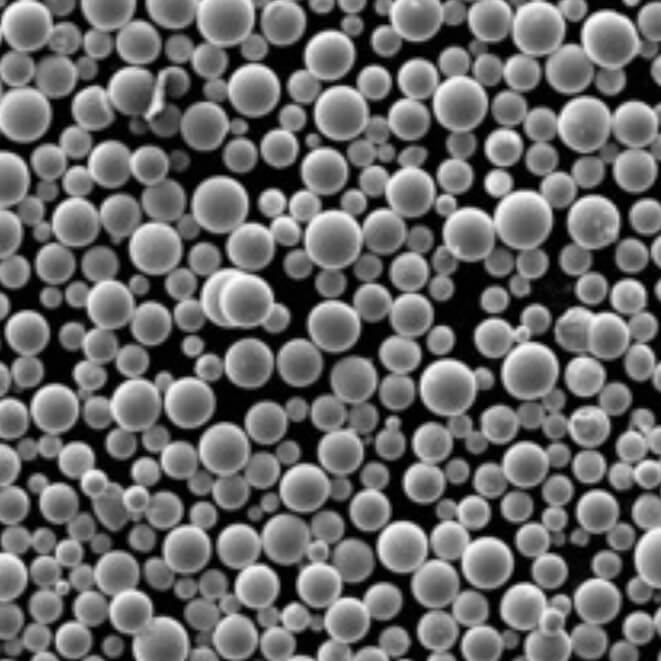

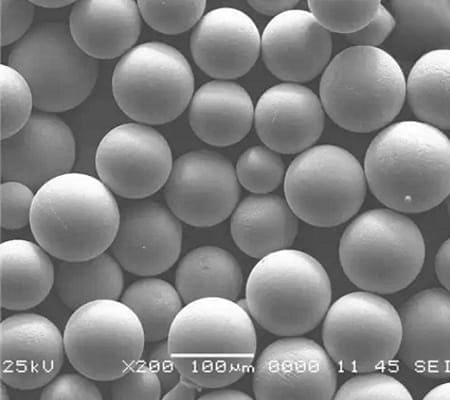

| Niobio esférico en polvo | 99.9+% | Alta fluidez, optimizada para la impresión 3D | Fabricación aditiva, componentes aeroespaciales |

| Niobio en polvo de calidad médica | 99.95+% | Biocompatible, resistente a la corrosión | Implantes quirúrgicos, revestimientos ortopédicos |

| Polvo superconductor de niobio | 99.99+% | Excelente superconductividad | Imanes superconductores, IRM, aceleradores de partículas |

| Carburo de niobio en polvo (NbC) | 99.9+% | Dureza extrema, alta resistencia al desgaste | Herramientas de corte, revestimientos antidesgaste |

Niobio superconductor es crucial para aplicaciones de física avanzadamientras que polvo esférico de niobio es esencial para Impresión 3D y aplicaciones aeroespaciales.

Solicite un presupuesto personalizado para polvos de niobio.

Productos relacionados

Aplicaciones del polvo de niobio en la industria

El polvo de niobio se utiliza en aplicaciones de alto rendimiento que requiere fuerza, conductividad y resistencia a la corrosión.

Aplicaciones industriales clave

| Industria | Aplicación | Ventajas |

|---|---|---|

| Electrónica | Condensadores, imanes superconductores | Alta conductividad, rendimiento estable |

| Medicina y sanidad | Implantes, revestimientos ortopédicos | Biocompatibilidad, resistencia a la corrosión |

| Aeroespacial y defensa | Superaleaciones, álabes de turbina | Alta resistencia y ligereza |

| Energía y superconductores | Imanes superconductores, reactores de fusión | Resistencia eléctrica cero, eficiencia energética |

| Fabricación aditiva (AM) | Piezas aeroespaciales y médicas impresas en 3D | Alta precisión, geometrías complejas |

Con el creciente demanda de electrónica avanzada, implantes biocompatibles y tecnologías superconductoras, polvo de niobio sigue siendo un material crítico para la innovación.

Descubra nuestros polvos de niobio de gran pureza.

Tamaño y forma de las partículas de niobio en polvo

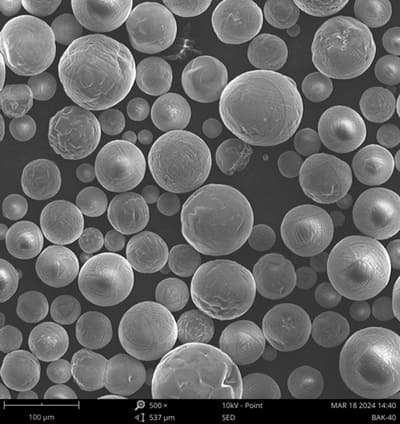

En distribución del tamaño de las partículas (PSD) y morfología impacto fluidez, rendimiento de sinterización y calidad del producto final en fabricación de condensadores, fabricación aditiva y revestimientos.

Tamaño óptimo de las partículas para aplicaciones de polvo de niobio

| Gama de tamaños de partículas | Mejor aplicación |

|---|---|

| 0,5-10 µm | Condensadores de alta capacidad |

| 10-45 µm | Implantes biomédicos, revestimientos |

| 45-150 µm | Impresión 3D, componentes aeroespaciales |

Polvo de niobio esférico frente a irregular: ¿cuál es mejor?

| Forma de polvo | Características | Mejor aplicación |

|---|---|---|

| Esférica | Alta fluidez, empaquetado uniforme, sinterización mejorada | Impresión 3D, aeroespacial, aplicaciones médicas |

| Irregular | Mayor superficie, mayor porosidad | Condensadores, revestimientos, procesamiento químico |

Polvos esféricos de niobio se prefieren para fabricación aditivamientras que polvos irregulares se utilizan en condensadores y revestimientos.

Explore nuestros polvos de niobio optimizados.

Normas de calidad para el polvo de niobio

Para garantizar alto rendimiento y coherenciaLos polvos de niobio deben cumplir normas internacionales estrictas que rige pureza, tamaño de las partículas, contenido de oxígeno y propiedades mecánicas. Estas normas son cruciales para industrias como electrónica, aeroespacial, médica y superconductores.

Principales normas de calidad del polvo de niobio

| Estándar | Descripción |

|---|---|

| ASTM B391 | Especificación para polvos de niobio y aleaciones de niobio utilizados en aplicaciones industriales. |

| ASTM F2063 | Norma para implantes médicos y dispositivos quirúrgicos a base de niobio para garantizar la biocompatibilidad. |

| ISO 23340 | Norma internacional para requisitos de pureza y transformación del polvo de niobio. |

| AMS 7852 | Especificación de materiales aeroespaciales para superaleaciones que contienen niobio. |

| Conformidad RoHS | Garantiza que los productos de niobio cumplir la normativa de seguridad medioambiental. |

¿Por qué elegir polvo de niobio certificado?

- Garantiza una pureza y un rendimiento constantes - Garantías durabilidad, resistencia a la corrosión y propiedades eléctricas.

- Crítico para uso aeroespacial y médico - Reuniones normas estrictas para aplicaciones de alto rendimiento.

- Optimizado para electrónica y superconductores - Garantiza alta conductividad y estabilidad.

- Cumplimiento global - Se adhiere a normas internacionales para aplicaciones de alta tecnología.

En Heeger Materials Inc., nuestro polvos de niobio de gran pureza cumplir Normas ASTM, ISO y AMSgarantizando calidad y fiabilidad superiores.

Análisis de costes del polvo de niobio

El precio de polvo de niobio depende de varios factores, entre ellos pureza, métodos de producción, distribución granulométrica y demanda de la industria. Debido a su uso creciente en tecnologías avanzadasEl niobio sigue siendo un material estratégico con tendencias de mercado fluctuantes.

Factores que influyen en el coste del polvo de niobio

- Pureza y calidad - El niobio de pureza ultra alta (99,99%) utilizado en superconductores es más caro que el niobio de grado condensador (99,9%).

- Método de producción - Los polvos de niobio atomizados por gas y procesados por plasma cuestan más que los polvos molidos mecánicamente.

- Distribución del tamaño de las partículas (PSD) - Los polvos más finos (0,5-10 µm) para condensadores y revestimientos requieren un procesamiento preciso, lo que eleva los costes..

- Disponibilidad de materias primas - El niobio procede principalmente de Brasil y Canadá, y las limitaciones de la oferta afectan a los precios.

- Demanda del mercado - Los precios fluctúan debido a creciente demanda de las industrias aeroespacial, médica y de superconductores.

Comparación de precios de las calidades de polvo de niobio

| Polvo de niobio Tipo | Coste ($/kg) | Caso de uso común |

|---|---|---|

| Niobio en polvo para condensadores | 300-300 - 300-1,000 | Condensadores electrónicos de alta capacidad |

| Niobio esférico en polvo (grado AM) | 500-500 - 500-2,000 | Impresión 3D, componentes aeroespaciales |

| Niobio en polvo de calidad médica | 700-700 - 700-2,500 | Implantes, revestimientos ortopédicos |

| Niobio superconductor en polvo (99,99%) | 1,500-1,500 - 1,500-4,000 | Máquinas de resonancia magnética, imanes superconductores |

| Carburo de niobio en polvo (NbC) | 500-500 - 500-1,500 | Recubrimientos antidesgaste, herramientas de corte |

Niobio superconductor domina industrias de alta tecnologíamientras que niobio para condensadores se utiliza ampliamente en electrónica.

Solicite un presupuesto de precios al por mayor de niobio en polvo.

Métodos de producción del polvo de niobio

Diferentes técnicas de producción de polvo impacto morfología, pureza y coste de las partículaspor lo que es esencial seleccionar el el mejor método para la aplicación prevista.

Comparación de los métodos de producción de polvo de niobio

| Método de producción | Forma de las partículas | Pureza | Coste | El mejor caso de uso |

|---|---|---|---|---|

| Hidruro-Dehidruro (HDH) | Irregular | Alta | $$ | Condensadores, revestimientos |

| Atomización de gas (GA) | Esférica | Muy alta | $$$ | Impresión 3D, piezas aeroespaciales |

| Atomización por plasma (PA) | Altamente esférico | Ultra Alta | $$$$ | Aplicaciones médicas, AM de alta precisión |

| Fresado mecánico | En forma de escamas | Moderado | $$ | Recubrimientos por pulverización, aplicaciones de sinterización |

Polvos de niobio atomizados con gas y tratados con plasma se prefieren para aplicaciones de alto rendimientogarantizando fluidez e imprimibilidad superiores.

Heeger Materials Inc. se especializa en polvos de niobio de gran pureza atomizados por gas para aplicaciones electrónicas, aeroespaciales y médicas.

Preguntas frecuentes sobre el polvo de niobio

| Pregunta | Respuesta |

|---|---|

| ¿Para qué se utiliza el polvo de niobio? | Se utiliza en condensadores, implantes médicos, componentes aeroespaciales, superconductores y revestimientos. |

| ¿Por qué es importante el niobio en los superconductores? | El niobio exhibe resistencia eléctrica nula a bajas temperaturaspor lo que es esencial para imanes superconductores y reactores de fusión. |

| ¿Cuál es el mejor polvo de niobio para impresión 3D? | Polvo esférico de niobio (45-150µm) es ideal para fabricación aditiva debido a su excelente fluidez y sinterización uniforme. |

| ¿Cómo se compara el niobio con el titanio para implantes médicos? | El niobio es altamente biocompatible y resistente a la corrosiónpor lo que es ideal para implantes quirúrgicos y revestimientos ortopédicos. |

| ¿Dónde puedo comprar polvo de niobio de gran pureza? | Heeger Materials Inc. proporciona polvos de niobio para aplicaciones industriales. |

Conclusión

Niobio en polvo es un material crítico para las industrias de alta tecnología, ofreciendo mayor resistencia a la corrosión, superconductividad y biocompatibilidad para electrónica, implantes médicos, aeroespacial y fabricación aditiva.

Para polvos de niobio de alta calidad, Heeger Materials Inc. proporciona soluciones a medida con polvos esféricos atomizados por gas de gran pureza.

¿Busca polvo de niobio de primera calidad? Póngase en contacto con nosotros

.jpg)