Aleación magnética blanda en polvo 2025: Materiales avanzados para aplicaciones magnéticas de alta eficiencia

Visión general

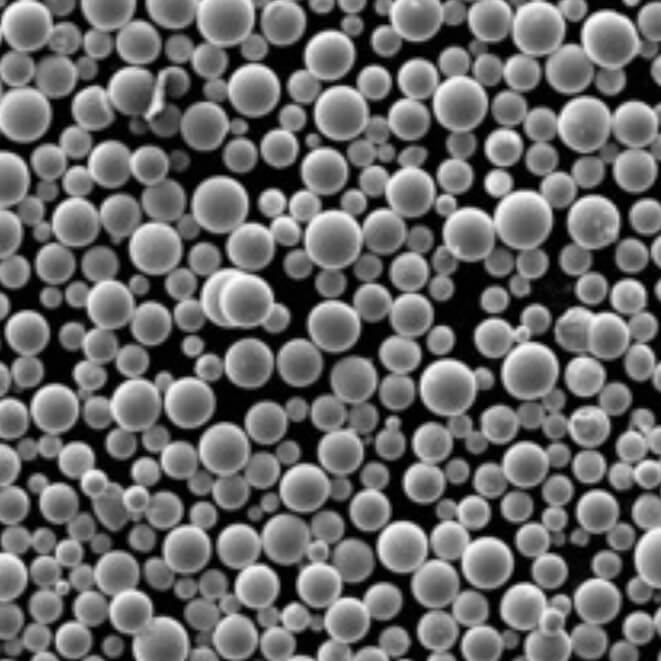

Polvo de aleación magnética blanda es un material especializado diseñado para aplicaciones electromagnéticas de alto rendimientoincluyendo motores eléctricos, transformadores, inductores y sistemas de carga inalámbricos. Estos polvos presentan alta permeabilidad, baja coercitividad y baja pérdida de núcleopor lo que son ideales para aplicaciones de alta frecuencia y diseños energéticamente eficientes.

Con la creciente demanda de componentes eléctricos ligeros y energéticamente eficientes, polvos de aleaciones magnéticas blandas están revolucionando sectores como automoción (motores de vehículos eléctricos), aeroespacial, telecomunicaciones y electrónica de potencia.

En Heeger Materials Inc.Estamos especializados en polvos de aleaciones magnéticas blandas personalizadas de gran pureza optimizado para aplicaciones electromagnéticas avanzadas.

¿Por qué elegir el polvo de aleación magnética blanda?

Los polvos magnéticos blandos son esencial para optimizar el rendimiento electromagnético en aplicaciones modernas en las que eficiencia energética, miniaturización y alta densidad de potencia son fundamentales.

Principales ventajas

- Alta permeabilidad magnética - Mejora conducción de flujo en componentes electromagnéticos.

- Baja coercitividad - Reduce pérdida de energía e histéresis.

- Baja pérdida de núcleo - Mejora eficiencia en aplicaciones de alta frecuencia.

- Excelente estabilidad térmica - Garantiza rendimiento constante en condiciones de funcionamiento variables.

- Tamaño y composición de partículas personalizables - A la medida de aplicaciones específicas como motores de alta velocidad e inductores de potencia.

En busca de ¿polvos de aleación magnética blanda optimizados? Explore la selección de Heeger Materials.

Productos relacionados

-

Polvo esférico de aleación magnética blanda Fe54Cr25Mo16B2C2.6 - Polvo Fe54Cr25Mo16B2C2.6 - Fabricación aditiva - Impresión 3D

-

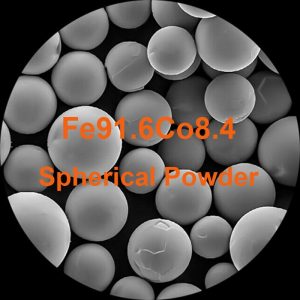

Polvo esférico de aleación magnética blanda Fe91.6Co8.4 - Polvo Fe91.6Co8.4 - Fabricación aditiva - Impresión 3D

-

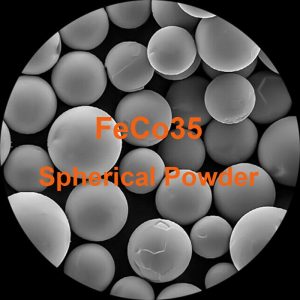

Polvo esférico de aleación magnética blanda FeCo35 - Polvo FeCo35 - Fabricación aditiva - Impresión 3D

-

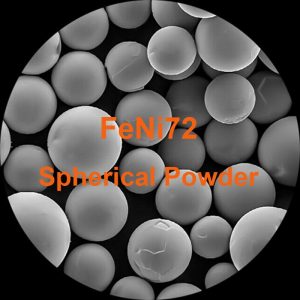

Polvo esférico de aleación magnética blanda FeNi72 - Polvo FeNi72 - Fabricación aditiva - Impresión 3D

Tipos comunes

Diferentes aleaciones magnéticas blandas están optimizados para aplicaciones específicas en función de su composición, permeabilidad y características de pérdida del núcleo.

Comparación

| Tipo de aleación | Propiedades clave | Aplicaciones comunes |

|---|---|---|

| Aleación hierro-silicio (Fe-Si) | Alta resistividad eléctrica, baja pérdida de núcleo | Transformadores, motores eléctricos |

| Aleación de hierro-níquel (Fe-Ni) (Permalloy) | Alta permeabilidad, baja coercitividad | Blindaje magnético, sensores, inductores |

| Aleación de hierro y cobalto (Fe-Co) | Alta magnetización de saturación, densidad de potencia superior | Aeroespacial, motores de alta velocidad |

| Polvos de ferrita blanda (ferritas de MnZn, NiZn) | Alta resistividad, utilizada en aplicaciones de alta frecuencia | Inductores, transformadores, carga inalámbrica |

| Polvos magnéticos amorfos y nanocristalinos | Pérdida de núcleo ultrabaja, eficiencia de alta frecuencia | Electrónica de potencia de alta eficiencia, componentes para vehículos eléctricos (VE) |

Aleaciones de hierro-silicio y hierro-níquel domina electrónica de potencia y transformadoresmientras que Aleaciones de hierro-cobalto se prefieren para aplicaciones aeroespaciales y de defensa de alto rendimiento.

Solicite un presupuesto personalizado para polvos de aleaciones magnéticas blandas.

Aplicaciones del polvo de aleación magnética blanda en la industria

Los polvos magnéticos blandos marcan el futuro del aplicaciones electromagnéticas y de eficiencia energética.

Aplicaciones industriales clave

| Industria | Aplicación | Ventajas |

|---|---|---|

| Automoción (motores EV) | Motores eléctricos de alta eficiencia | Menor pérdida de energía, mayor densidad de par |

| Electrónica de potencia | Inductores, transformadores | Mayor eficiencia energética, menor generación de calor |

| Aeroespacial y defensa | Actuadores de alta velocidad, blindaje magnético | Materiales ligeros y de alto rendimiento |

| Energías renovables | Generadores eólicos | Mayor eficiencia en la conversión de energía |

| Telecomunicaciones | Sistemas de carga inalámbrica, filtros | Estabilidad de alta frecuencia, miniaturización |

Con el auge de vehículos eléctricos (VE) y las energías renovables, polvos de aleaciones magnéticas blandas desempeñan un papel crucial en conversión de potencia y eficiencia del motor.

Descubra nuestros polvos magnéticos blandos de alto rendimiento.

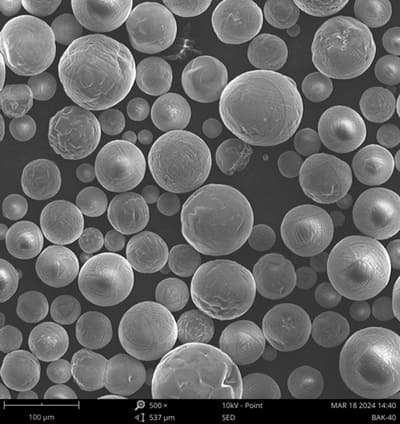

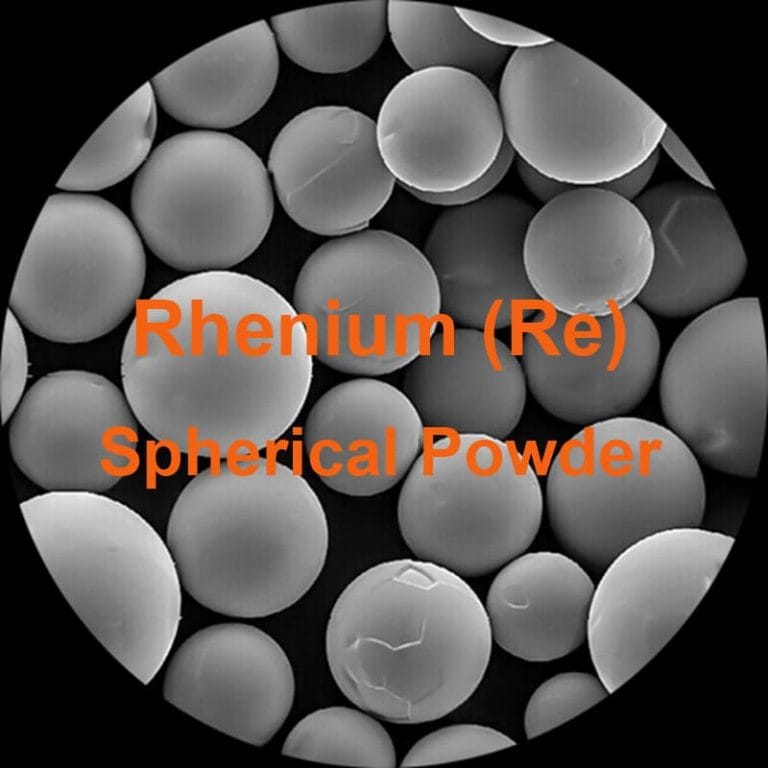

Tamaño y forma de las partículas en polvos de aleaciones magnéticas blandas

En distribución del tamaño de las partículas (PSD) y morfología impactar significativamente rendimiento magnético, permeabilidad y pérdida de núcleo.

Tamaño óptimo de las partículas para aplicaciones magnéticas blandas

| Gama de tamaños de partículas | Mejor aplicación |

|---|---|

| 1-10 µm | Inductores de alta frecuencia, transformadores |

| 10-45 µm | Blindaje electromagnético, sensores |

| 45-150 µm | Motores eléctricos, electrónica de potencia |

Polvo esférico frente a polvo irregular: ¿cuál es mejor?

| Forma de polvo | Características | Mejor aplicación |

|---|---|---|

| Esférica | Mayor densidad de empaquetamiento, mejor permeabilidad, menor pérdida por corrientes parásitas | Aplicaciones de alta frecuencia, electrónica de potencia |

| Irregular | Mayor superficie, menor coste | Blindaje magnético, aplicaciones generales |

Polvos magnéticos blandos esféricos se prefieren para aplicaciones de alta frecuencia y alto rendimientogarantizando propiedades magnéticas superiores.

Explore nuestros polvos optimizados de aleaciones magnéticas blandas.

Principales proveedores de aleaciones magnéticas blandas en polvo en 2025

Encontrar un proveedor fiable es crucial para calidad y rendimiento constantes del polvo de aleación magnética blanda.

Principales proveedores de aleaciones magnéticas blandas en polvo

| Nombre del proveedor | País | Especialización | Métodos de producción | Página web |

|---|---|---|---|---|

| Heeger Materials Inc. | EE.UU | Polvos de aleaciones magnéticas blandas | VIGA, PREP, Atomización con gas | Visitar el sitio |

| Höganäs | Suecia | Polvos magnéticos blandos | Atomización del agua | N/A |

| Hitachi Metales | Japón | Materiales magnéticos de alto rendimiento | Atomización de gases | N/A |

| Grupo VAC | Alemania | Polvos amorfos y nanocristalinos | Atomización de gases | N/A |

Heeger Materials Inc. se especializa en polvos de aleación magnética blanda personalizadosentregando materiales de alta calidad y rendimiento para aplicaciones electromagnéticas.

Póngase en contacto con Heeger Materials para obtener polvos magnéticos blandos de primera calidad.

Normas de calidad para polvos de aleaciones magnéticas blandas

Garantizar polvos de aleación magnética blanda de alta calidad es crucial para conversión eficiente de la energía, reducción de las pérdidas en el núcleo y mejora del rendimiento electromagnético. Varios normas internacionales regular la composición, el tamaño de las partículas y las propiedades magnéticas de estos polvos para satisfacer requisitos aeroespaciales, automovilísticos e industriales.

Principales normas de calidad para polvos de aleaciones magnéticas blandas

| Estándar | Descripción |

|---|---|

| ASTM A804 | Norma para aleaciones magnéticas blandas a base de hierro. |

| ASTM A839 | Especificación para Aleaciones magnéticas blandas de hierro, cobalto y vanadio. |

| IEC 60404-8-6 | Clasificación de Polvos magnéticos blandos Fe-Si. |

| ISO 3934 | Directrices para pulvimetalurgia materiales magnéticos blandos. |

| JIS C 2524 | La norma japonesa para materiales de núcleo magnético blando. |

| Conformidad RoHS | Garantiza seguridad medioambiental mediante la limitación de sustancias peligrosas. |

¿Por qué elegir polvos de aleación magnética blanda certificados?

- Garantiza propiedades magnéticas constantes - Mantiene permeabilidad uniforme y baja coercitividad.

- Optimizado para aplicaciones de alta frecuencia - Minimiza pérdidas por corrientes de Foucault en transformadores e inductores.

- Polvos de gran pureza - Reduce impurezas que degradan el rendimiento magnético.

- Cumplimiento de las normas aeroespaciales y de automoción - Garantiza seguridad y eficiencia en las aplicaciones de motores eléctricos.

En Heeger Materials Inc.fabricamos polvos magnéticos blandos de gran pureza que cumplan Normas ASTM, ISO e IECgarantizando rendimiento electromagnético óptimo.

Análisis de costes de los polvos de aleaciones magnéticas blandas

El precio de polvos de aleaciones magnéticas blandas depende de composición del material, método de producción y requisitos de aplicación.

Factores que influyen en el coste del polvo de aleación magnética blanda

- Composición del material - Hierro-cobalto y aleaciones nanocristalinas son más caros que Aleaciones Fe-Si y Fe-Ni.

- Método de producción - Atomización con gas y atomización con plasma producir polvos esféricos de mayor calidadaumentando los costes.

- Distribución del tamaño de las partículas (PSD) - Los polvos más finos (1-10µm) para aplicaciones de alta frecuencia son más caros debido a mayor precisión de procesamiento.

- Pureza magnética - Menos impurezas y contenido de oxígeno controlado mejorar el rendimiento pero aumentar los costes de producción.

- Oferta y demanda mundiales - Los precios fluctúan en función de disponibilidad de materias primas y tendencias del sector.

Comparación de precios de los polvos de aleaciones magnéticas blandas

| Tipo de aleación | Coste ($/kg) | Caso de uso común |

|---|---|---|

| Aleación Fe-Si (Hierro-Silicio) | 50-50 – 50-150 | Transformadores, motores eléctricos |

| Aleación Fe-Ni (Permalloy) | 100-100 – 100-300 | Blindaje magnético, sensores |

| Aleación Fe-Co (hierro-cobalto) | 300-300 - 300-700 | Aeroespacial, motores de alta velocidad |

| Polvos magnéticos nanocristalinos | 500-500 - 500-1,200 | Electrónica de potencia de alta frecuencia |

| Polvos de ferrita blanda | 30-30 - 30-100 | Inductores, carga inalámbrica |

Nanocristalino y aleaciones Fe-Co son más caro debido a su eficiencia y densidad de potencia superiores en alta frecuenciamientras que Fe-Si y polvos de ferrita oferta soluciones rentables para aplicaciones industriales.

Solicite un presupuesto personalizado para pedidos al por mayor.

Métodos de producción de polvos de aleaciones magnéticas blandas

Diferentes técnicas de producción de polvo impact the forma, pureza y coste de las partículas de polvos de aleaciones magnéticas blandas.

Comparación de los métodos de producción de polvo

| Método de producción | Forma de las partículas | Pureza | Coste | El mejor caso de uso |

|---|---|---|---|---|

| Atomización de gas (GA) | Esférica | Alta | $$$ | Motores eléctricos, transformadores |

| Atomización por plasma (PA) | Altamente esférico | Muy alta | $$$$ | Inductores de alta frecuencia, aplicaciones aeroespaciales |

| Atomización del agua (WA) | Irregular | Moderado | $$ | Blindaje magnético, aplicaciones generales |

| Fresado mecánico | En forma de escamas | Moderado | $$ | Núcleos magnéticos, sensores |

Atomización con gas y atomización con plasma métodos son preferibles para aplicaciones electromagnéticas de alto rendimientogarantizando excelente pureza, esfericidad y rendimiento magnético.

Heeger Materials Inc. se especializa en polvos magnéticos blandos atomizados por gas y plasmaentregando materiales de alta calidad para aplicaciones avanzadas.

Preguntas frecuentes sobre los polvos de aleaciones magnéticas blandas

| Pregunta | Respuesta |

|---|---|

| ¿Para qué se utilizan los polvos de aleaciones magnéticas blandas? | Se utilizan en motores eléctricos, transformadores, inductores y blindaje magnético para aplicaciones electromagnéticas de alta eficiencia. |

| ¿Cuál es el mejor material magnético blando para aplicaciones de alta frecuencia? | Polvos magnéticos nanocristalinos y amorfos oferta pérdidas en el núcleo ultrabajas y excelente rendimiento a alta frecuencia. |

| ¿Cuál es la diferencia entre las aleaciones magnéticas blandas Fe-Si y Fe-Ni? | Aleaciones Fe-Si proporcionar baja pérdida en el núcleo y alta resistividad eléctricamientras que Las aleaciones Fe-Ni (Permalloy) ofrecen alta permeabilidad y baja coercitividad. |

| ¿Cuál es la granulometría típica de los polvos magnéticos blandos? | 1-10 µm para aplicaciones de alta frecuencia, 10-45 µm para blindaje y 45-150 µm para motores eléctricos. |

| ¿Dónde puedo comprar polvo de aleación magnética blanda de alta calidad? | Heeger Materials Inc. proporciona polvos magnéticos blandos para aplicaciones industriales. |

Conclusión

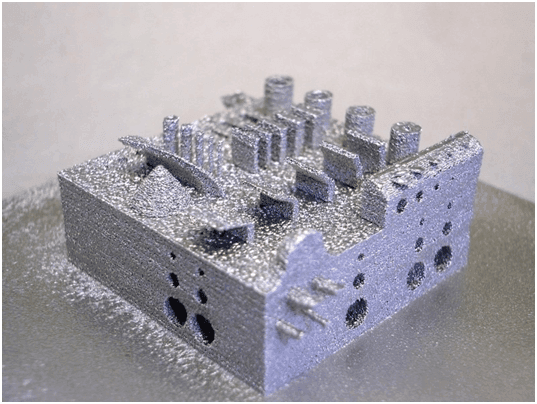

Polvos de aleaciones magnéticas blandas están impulsando innovaciones en aplicaciones electromagnéticaspermitiendo mayor eficiencia energética, mejores prestaciones y miniaturización en sectores como Motores de vehículos eléctricos, electrónica de potencia y aeroespacial.

Para polvos de aleación magnética blanda de alta calidad, Heeger Materials Inc. proporciona soluciones a medida con polvos esféricos atomizados por gas de gran pureza.

¿Busca polvo de aleación magnética blanda de primera calidad? Póngase en contacto con nosotros

.jpg)