Rociado térmico 2025: La guía definitiva de tecnologías y materiales de recubrimiento

Visión general

Pulverización térmica es un avanzado proceso de revestimiento de superficies que se aplica polvos metálicos, cerámicos o compuestos sobre un sustrato utilizando técnicas térmicas de alta energía como pulverización de plasma, pulverización de llama, HVOF (High-Velocity Oxygen Fuel) y pulverización en frío. Este proceso mejora resistencia al desgaste, resistencia a la corrosión, resistencia al calor y conductividad eléctricalo que la convierte en una tecnología esencial en industrias aeroespacial, automovilística, médica y energética.

En los fabricantes buscan revestimientos superiores para entornos extremos, pulverización térmica se ha convertido en una solución indispensable, que ofrece revestimientos de alto rendimiento para componentes de motores, álabes de turbinas, implantes biomédicos y maquinaria industrial.

¿Por qué elegir la pulverización térmica para revestimientos?

La pulverización térmica proporciona revestimientos protectores superiores en comparación con galvanoplastia, anodizado y pintura debido a su alta velocidad de deposición, gran adherencia y capacidad para recubrir grandes superficies.

Principales ventajas

- Mayor resistencia al desgaste - Protege contra abrasión, erosión y daños por impacto.

- Protección superior contra la corrosión - Ideal para entornos marinos, aeroespaciales e industriales.

- Resistencia a altas temperaturas - Imprescindible para turbina de gass, sistemas de escape e intercambiadores de calor.

- Selección de materiales personalizable - Soportes metales, cerámicas, compuestos y polímeros.

- Distorsión térmica mínima - A diferencia de la soldadura, la pulverización térmica no provoca alabeos ni cambios estructurales.

En busca de polvos de proyección térmica de alto rendimiento? Explore la selección de Heeger Materials.

Tipos

Diferentes técnicas de pulverización térmica varían en temperatura, velocidad y calidad del revestimientoCada uno de ellos es apto para aplicaciones específicas.

Comparación

| Método de pulverización | Temperatura de proceso | Adherencia del revestimiento | Mejores aplicaciones |

|---|---|---|---|

| Pulverización de plasma (APS, VPS) | 10,000-15,000°C | Fuerte | Aeroespacial, implantes biomédicos, revestimientos de alta temperatura |

| Combustible de oxígeno a alta velocidad (HVOF) | 2,500-3,000°C | Muy fuerte | Revestimientos antidesgaste, álabes de turbina, componentes aeroespaciales |

| Pulverización en frío | Por debajo de 800°C | Moderado | Aluminio, revestimientos de cobre, electrónica, revestimientos resistentes a la corrosión |

| Rociado con llama | 2,500-3,000°C | Moderado | Recubrimientos a gran escala, protección de maquinaria industrial |

| Rociado por arco | 5,000-6,000°C | Fuerte | Protección contra la corrosión, componentes estructurales |

Pulverización HVOF y de plasma son los métodos más utilizados para aplicaciones aeroespaciales, médicas e industrialesentregando revestimientos de alta densidad con excelente adherencia.

Encuentre el mejor polvo para su proceso de pulverización térmica.

Productos relacionados

-

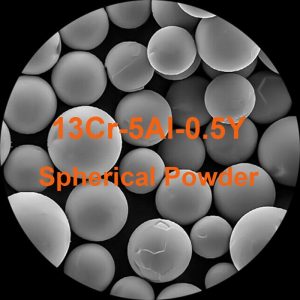

Polvo esférico de aleación 13Cr-5Al-0.5Y para pulverización térmica - Polvo 13Cr-5Al-0.5Y - Fabricación aditiva - Impresión 3D

-

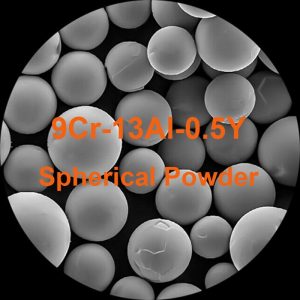

Polvo esférico de aleación 9Cr-13Al-0.5Y para pulverización térmica - Polvo 9Cr-13Al-0.5Y - Fabricación aditiva - Impresión 3D

-

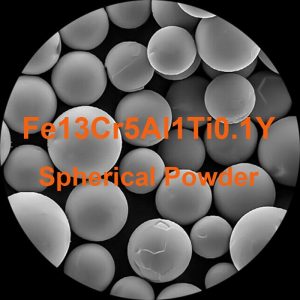

Polvo esférico de aleación Fe13Cr5Al1Ti0.1Y para pulverización térmica - Polvo Fe13Cr5Al1Ti0.1Y - Fabricación aditiva - Impresión 3D

-

Polvo esférico de aleación Ni-Al-Co-Cr-Si-Y para pulverización térmica - Polvo Ni-Al-Co-Cr-Si-Y - Fabricación aditiva - Impresión 3D

Los mejores materiales

Elegir el polvo de pulverización térmica adecuado depende de requisitos de aplicación, condiciones ambientales y rendimiento del revestimiento.

Común

| Tipo de material | Principales ventajas | Aplicaciones comunes |

|---|---|---|

| Aleaciones a base de níquel (Inconel 625, 718) | Resistencia a altas temperaturas, protección contra la corrosión | Aeroespacial, generación de energía |

| Aleaciones a base de cobalto (Stellite 6, 21) | Resistencia al desgaste y a la oxidación | Implantes médicos, herramientas de corte |

| Carburo de wolframio (WC-Co, WC-Ni) | Dureza extrema, resistente al desgaste | Álabes de turbina, componentes de bombas |

| Aluminio y zinc en polvo | Protección contra la corrosión, ligero | Marina, automoción, infraestructuras |

| Carburo de cromo (Cr3C2-NiCr) | Resistencia a la oxidación a altas temperaturas | Motores a reacción, plantas químicas |

| Polvos cerámicos (alúmina, circonio, YSZ) | Revestimientos de barrera térmica, aislamiento eléctrico | Turbinas de gas, biomedicina, electrónica |

Recubrimientos a base de níquel y carburo de wolframio domina aplicaciones a alta temperatura y resistentes al desgastemientras que recubrimientos cerámicos proporcionar aislamiento térmico para equipos aeroespaciales e industriales.

Solicite presupuesto para polvos de proyección térmica premium.

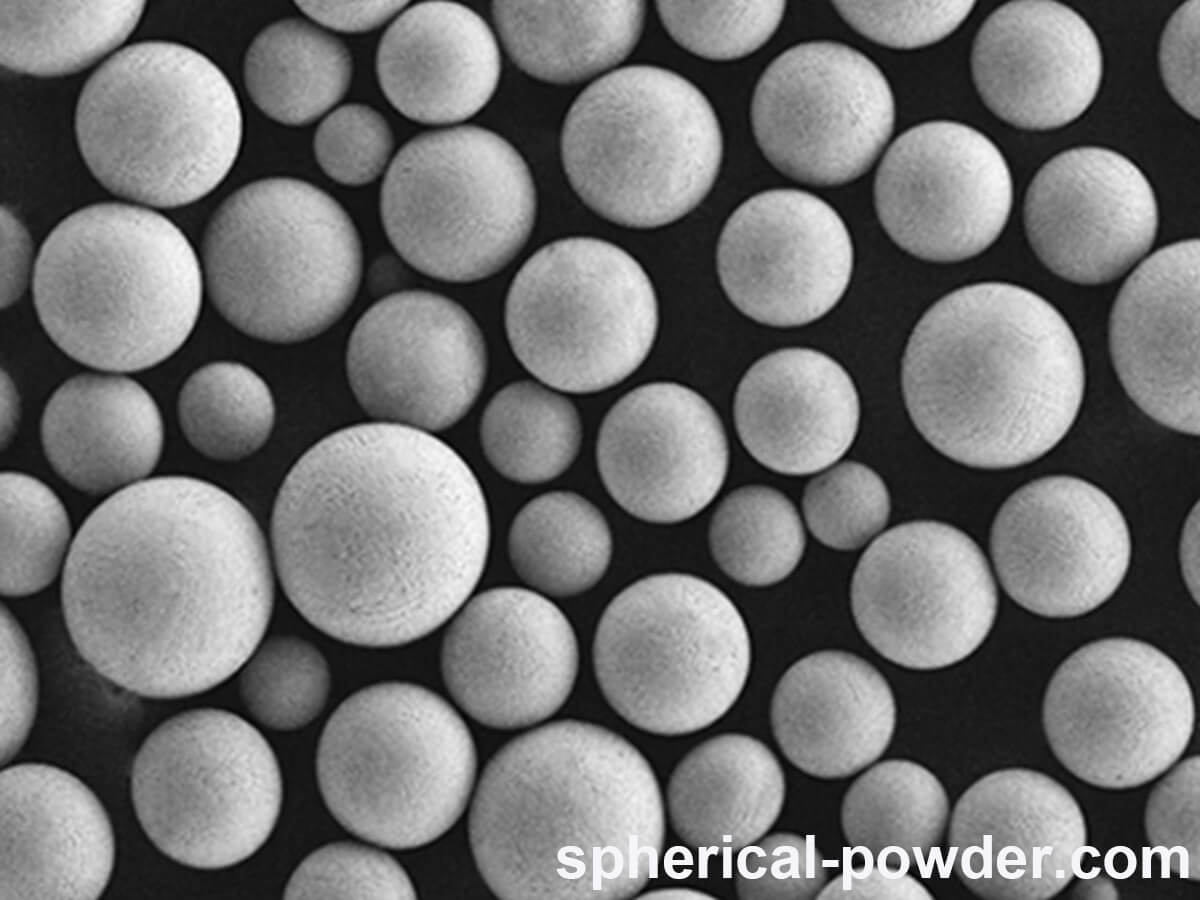

Tamaño y forma de las partículas

En distribución del tamaño de las partículas (PSD) y morfología desempeñan un papel clave en densidad, adherencia y rendimiento del revestimiento en aplicaciones de la pulverización térmica.

Tamaño óptimo de las partículas

| Gama de tamaños de partículas | Mejor aplicación |

|---|---|

| 5-25 µm | Pulverización de plasma (APS, VPS) |

| 15-45 µm | HVOF, pulverización con llama |

| 45-75 µm | Pulverización en frío, pulverización por arco |

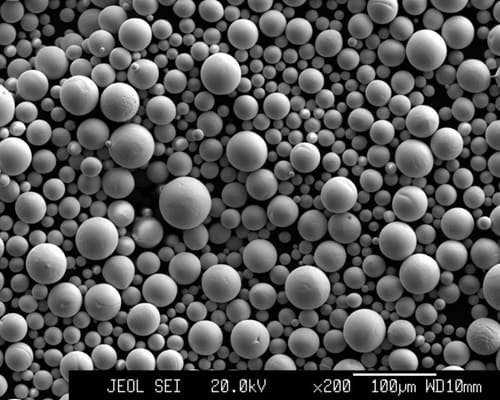

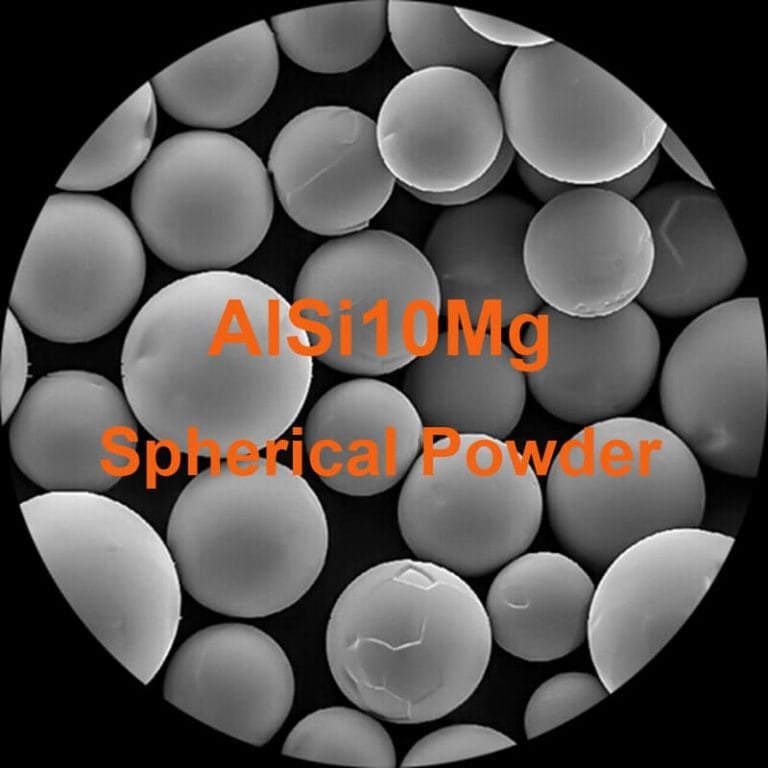

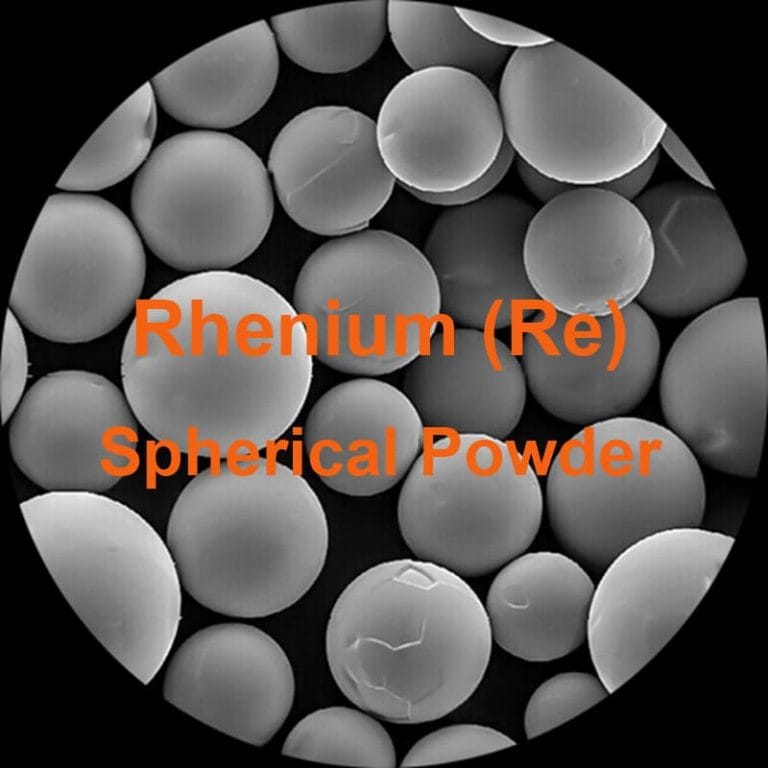

Polvo esférico frente a polvo irregular: ¿cuál es mejor?

| Forma de polvo | Características | Mejor aplicación |

|---|---|---|

| Esférica | Excelente fluidez, empaquetado uniforme, alta adherencia | HVOF, pulverización de plasma |

| Irregular | Menor fluidez, revestimientos más rugosos, menor coste | Rociado por llama, rociado por arco |

Polvos esféricos se prefieren para pulverización térmicagarantizando mejor fluidez, recubrimiento uniforme y defectos mínimos.

Descubra nuestros polvos de proyección térmica esféricos de alta calidad.

Principales proveedores en 2025

Encontrar un proveedor fiable es crucial para calidad y rendimiento constantes del revestimiento en aplicaciones de la pulverización térmica.

Principales proveedores

| Nombre del proveedor | País | Especialización | Métodos de producción | Página web |

|---|---|---|---|---|

| Heeger Materials Inc. | EE.UU | Pulverización térmica de polvos metálicos | VIGA, PREP, Atomización con gas | Visitar el sitio |

| Höganäs | Suecia | Polvos metálicos y cerámicos | Atomización del agua | N/A |

| Oerlikon Metco | Suiza | Recubrimientos aeroespaciales e industriales | Atomización de gases | N/A |

| Sandvik | Suecia | Recubrimientos duros y polvos antidesgaste | Atomización de gases | N/A |

En busca de polvos de proyección térmica de alto rendimiento? Póngase en contacto con Heeger Materials hoy mismo.

Normas de calidad

Garantizar polvos de proyección térmica de alta calidad es esencial para rendimiento, adherencia y durabilidad óptimos del revestimiento. Varios normas internacionales rigen la composición, tamaño de las partículas, fluidez y pureza de estos polvos para satisfacer requisitos aeroespaciales, médicos e industriales.

Principales normas de calidad

| Estándar | Descripción |

|---|---|

| ASTM B214 | Norma para análisis de la distribución granulométrica de polvos metálicos. |

| ASTM C633 | Método de ensayo para resistencia a la adherencia de los revestimientos de proyección térmica. |

| ISO 14922 | Directrices para cualificación del proceso de pulverización térmica. |

| AMS 4775 | Especificación de materiales aeroespaciales para polvos de proyección térmica a base de níquel. |

| ISO 14923 | Norma para evaluación de la calidad de los revestimientos de proyección térmica. |

| Conformidad RoHS | Garantiza seguridad medioambiental mediante la restricción de sustancias peligrosas. |

¿Por qué elegir polvos de proyección térmica certificados?

- Garantiza un tamaño y una forma uniformes de las partículas - Proporciona deposición por pulverización uniforme.

- Propiedades de revestimiento superiores - Reuniones estrictos requisitos de adherencia, resistencia al desgaste y estabilidad térmica.

- Oxígeno bajo y contaminantes - Los polvos de gran pureza mejoran integridad y rendimiento del revestimiento.

- Cumplimiento de la normativa aeroespacial y de la normativa médica - Garantiza seguridad y fiabilidad en aplicaciones críticas.

En Heeger Materials Inc.fabricamos polvos de proyección térmica de gran pureza que cumplan Normas ASTM, AMS e ISOgarantizando rendimiento de pulverización y durabilidad óptimos.

Análisis de costes

El precio de polvos de proyección térmica depende de tipo de material, tamaño de las partículas y método de producción.

Factores que influyen en el coste del polvo de proyección térmica

- Composición del material base - Las aleaciones de alto rendimiento (níquel, cobalto, carburo de tungsteno) cuestan más que los polvos a base de aluminio o zinc..

- Método de producción - Atomización con gas y atomización con plasma producir polvos esféricos de mayor calidadaumentando los costes.

- Distribución del tamaño de las partículas (PSD) - Los polvos más finos (5-25µm) para la pulverización de plasma son más caros debido a mayores requisitos de precisión.

- Pureza y contenido de oxígeno - Los niveles más bajos de oxígeno mejoran el rendimiento del revestimiento pero aumentan los costes.

- Oferta y demanda mundiales - Los precios fluctúan en función de disponibilidad de materias primas y necesidades de la industria.

Comparación de precios

| Tipo de polvo | Coste ($/kg) | Caso de uso común |

|---|---|---|

| Aleación a base de níquel (Inconel 625, 718) | 200-200 - 200-600 | Aeroespacial, turbinas de gas |

| Aleación a base de cobalto (estelita 6, 21) | 250-250 - 250-700 | Implantes médicos, revestimientos resistentes al desgaste |

| Carburo de wolframio (WC-Co, WC-Ni) | 400-400 - 400-1,000 | Aplicaciones de alto desgaste, álabes de turbina |

| Carburo de cromo (Cr3C2-NiCr) | 300-300 - 300-800 | Resistencia a la corrosión a altas temperaturas |

| Aluminio y zinc en polvo | 50-50 – 50-150 | Protección contra la corrosión, revestimientos marinos |

Polvos a base de níquel y carburo de wolframio son más caro debido a su aplicaciones de alto rendimientomientras que polvos de aluminio y zinc oferta protección anticorrosión rentable.

Solicite un presupuesto personalizado para pedidos al por mayor.

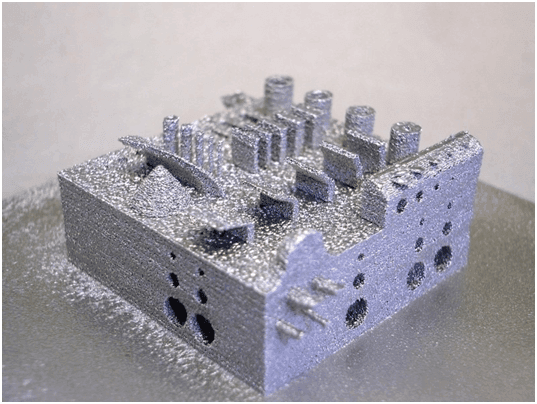

Métodos de producción

Diferentes métodos de producción de polvo impact the forma, pureza y coste de las partículas de polvos de proyección térmica.

Comparación de los métodos de producción de polvo

| Método de producción | Forma de las partículas | Pureza | Coste | El mejor caso de uso |

|---|---|---|---|---|

| Atomización de gas (GA) | Esférica | Alta | $$$ | HVOF, pulverización de plasma |

| Atomización por plasma (PA) | Altamente esférico | Muy alta | $$$$ | Medicina, aeroespacial |

| Atomización del agua (WA) | Irregular | Moderado | $$ | Rociado por llama, rociado por arco |

| PREP (Proceso de Electrodo Rotatorio de Plasma) | Extremadamente esférico | Ultra Alta | $$$$$ | Aplicaciones aeroespaciales y médicas de alto rendimiento |

Atomización con gas y atomización con plasma son los métodos más utilizados para polvos de proyección térmicagarantizando excelente pureza, esfericidad y rendimiento de recubrimiento.

Heeger Materials Inc. se especializa en polvos de pulverización térmica atomizados por gas y plasmaentregando calidad y consistencia superiores.

PREGUNTAS FRECUENTES

| Pregunta | Respuesta |

|---|---|

| ¿Para qué sirve? | Se utiliza para revestimientos protectores, resistencia al desgaste, resistencia a la corrosión y aislamiento térmico en aplicaciones aeroespaciales, médicas, marinas e industriales. |

| ¿Cuál es el mejor método de pulverización térmica para la resistencia al desgaste? | Pulverización HVOF y de plasma son ideales para revestimientos resistentes al desgaste, como el carburo de wolframio y las aleaciones de estelita. |

| ¿Cuál es la diferencia entre la pulverización HVOF y la pulverización de plasma? | HVOF produce revestimientos densos y de alta adherenciamientras que la pulverización de plasma es mejor para materiales de alto punto de fusión, como la cerámica. |

| ¿Cuál es el tamaño típico de sus partículas? | 5-25µm para la pulverización de plasma, 15-45µm para HVOF y 45-75µm para la pulverización en frío. |

| ¿Dónde puedo comprar polvo de proyección térmica de alta calidad? | Heeger Materials Inc. proporciona polvos de proyección térmica para aplicaciones industriales. |

Conclusión

En es un tecnología punta de revestimiento de superficies, ofreciendo resistencia superior al desgaste, protección contra la corrosión y resistencia a altas temperaturas para componentes críticos en diversas industrias.

Para polvos de proyección térmica de alta calidad, Heeger Materials Inc. proporciona soluciones a medida con polvos esféricos atomizados por gas de gran pureza.

¿Busca polvo de proyección térmica de alta calidad? Póngase en contacto con nosotros