Aleación en polvo personalizada 2025: Soluciones a medida para la fabricación avanzada

Visión general de la aleación en polvo personalizada

Polvo de aleación a medida se refiere a polvos metálicos a medida diseñado para cumplir requisitos industriales específicos en sectores aeroespacial, médico, automovilístico y energético. Estos polvos están diseñados para proporcionar propiedades mecánicas, resistencia a la corrosión, estabilidad térmica e imprimibilidad óptimas para varios aplicaciones de fabricación aditiva (AM), moldeo por inyección de metales (MIM) y revestimiento por láser.

Con el rápido crecimiento de impresión 3D y pulvimetalurgiademanda de las industrias polvos de aleación de alto rendimiento que van más allá de las composiciones estándar. Empresas como Heeger Materials Inc. se especializan en desarrollar polvos metálicos personalizados para satisfacer las especificaciones exclusivas de los clientes.

¿Por qué elegir polvo de aleación personalizado?

Elegir aleación en polvo personalizada permite a los fabricantes conseguir control preciso de las propiedades de los materiales, garantizando una mejor rendimiento, eficacia y fiabilidad en sus aplicaciones.

Principales ventajas de la aleación en polvo personalizada

- Propiedades optimizadas de los materiales - A la medida de resistencia específica, dureza, conductividad y dilatación térmica.

- Imprimibilidad mejorada - Diseñado para Fabricación aditiva LPBF, EBM, Binder Jetting y DED.

- Mayor resistencia a la corrosión y al desgaste - Ideal para entornos difíciles, aplicaciones aeroespaciales y médicas.

- Distribución granulométrica (PSD) a medida - Personalización de polvos finos (15-45µm), medios (45-75µm) o gruesos (75-150µm).

- Alta pureza y bajo contenido de oxígeno - Garantiza propiedades mecánicas superiores y defectos reducidos.

En busca de un polvo de aleación específico a medida? Póngase en contacto con Heeger Materials para obtener soluciones a medida.

Tipos comunes de polvos de aleación personalizados

Composiciones populares de aleación en polvo a medida

| Tipo de aleación | Propiedades clave | Aplicaciones comunes |

|---|---|---|

| Aleaciones a base de níquel | Resistencia a altas temperaturas, resistente a la oxidación | Aeroespacial, turbinas de gas, energía |

| Aleaciones de titanio | Ligero, biocompatible, alta relación resistencia/peso | Implantes médicos, aeroespacial |

| Aleaciones a base de cobalto | Resistencia al desgaste y a la corrosión, excelente resistencia | Herramientas médicas, dentales e industriales |

| Aleaciones de alta entropía (HEA) | Resistencia, dureza y estabilidad térmica superiores | Aeroespacial, defensa, investigación avanzada |

| Aleaciones a base de wolframio | Alta densidad, blindaje contra las radiaciones, resistencia extrema al calor | Defensa, nuclear, aeroespacial |

| Aleaciones de aluminio | Ligero, buena conductividad térmica, resistencia a la corrosión | Automoción, marina, aeroespacial |

Heeger Materials Inc. se especializa en desarrollo de polvos de aleación a medida basado en especificaciones del clientegarantizando rendimiento y capacidad de impresión óptimos.

Explore nuestra amplia gama de polvos de aleación personalizados.

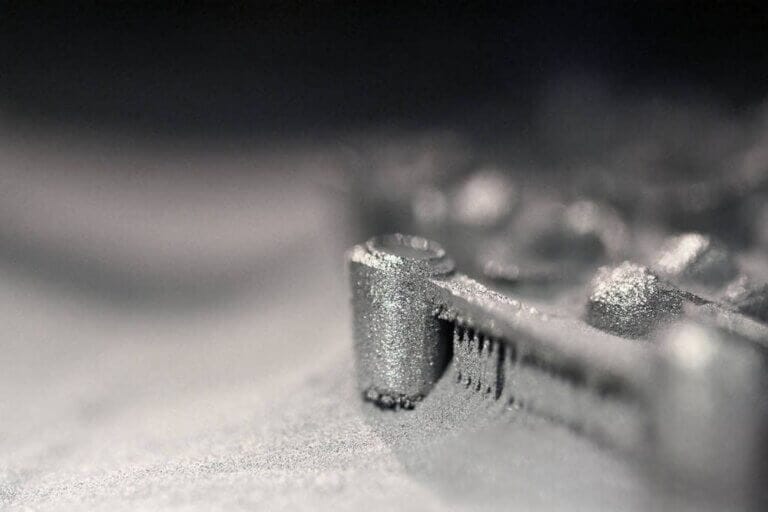

Polvo de aleación a medida para fabricación aditiva (AM)

¿Por qué utilizar polvo de aleación personalizado para la impresión 3D?

- Fluidez y densidad de empaquetado optimizadas - Garantiza mejor unión de capas e impresión sin defectos.

- Composición de aleación a medida - Diseñado para aplicaciones de alta resistencia, ligeras y resistentes a la corrosión.

- Compatible con múltiples tecnologías AM - Adecuado para Procesos LPBF, SLM, EBM y DED.

- Acabado superficial y propiedades mecánicas superiores - Mejora calidad y durabilidad de la pieza final.

Los mejores polvos de aleación a medida para la fabricación aditiva

| Tipo de aleación | Mejor proceso AM | Principales ventajas |

|---|---|---|

| Aleaciones de titanio a medida | LPBF, EBM | Ligero, de alta resistencia, biocompatible |

| Superaleaciones de níquel (a base de Inconel) | LPBF, DED | Resistencia a altas temperaturas y a la oxidación |

| Aleaciones de alta entropía (HEA) | LPBF, SLM | Propiedades mecánicas superiores, estabilidad térmica |

| Aleaciones personalizadas a base de aluminio | Chorro aglomerante, LPBF | Ligero, resistente a la corrosión |

| Aleaciones a base de wolframio | LPBF, DED | Alta densidad, blindaje contra las radiaciones |

Solicite una muestra de nuestros polvos de aleación personalizados de alta calidad.

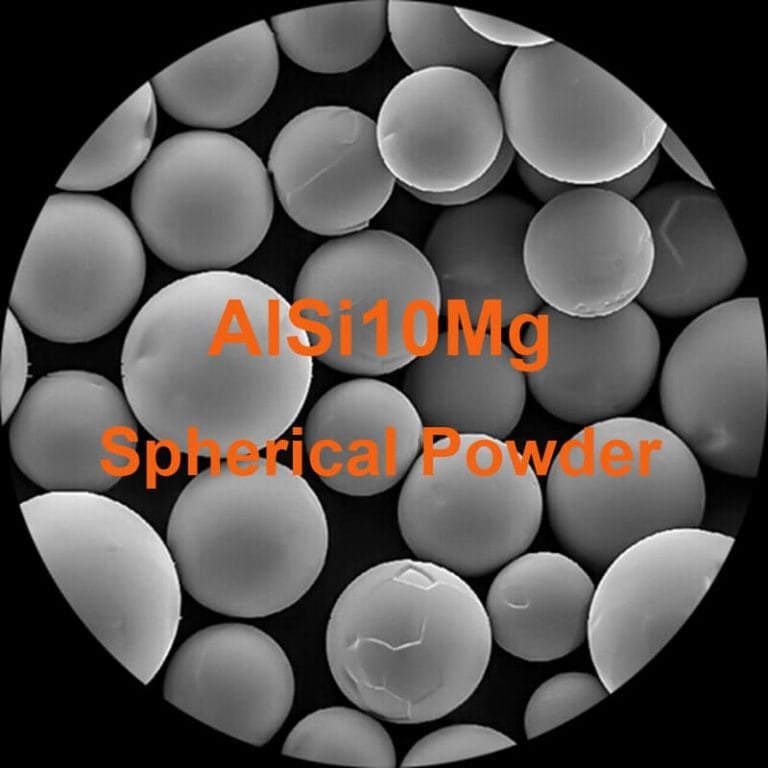

Tamaño y forma de las partículas en el polvo de aleación personalizado

En distribución del tamaño de las partículas (PSD) y morfología desempeñan un papel crucial en fluidez, imprimibilidad y propiedades mecánicas en fabricación aditiva y pulvimetalurgia.

Distribución granulométrica de polvos de aleación a medida

| Gama de tamaños de partículas | Mejor aplicación |

|---|---|

| 15-45 µm | LPBF, SLM (fusión de lecho de polvo láser) |

| 45-75 µm | EBM, DED (fusión por haz de electrones, deposición directa de energía) |

| 75-150 µm | MIM, inyección de ligante, pulverización térmica |

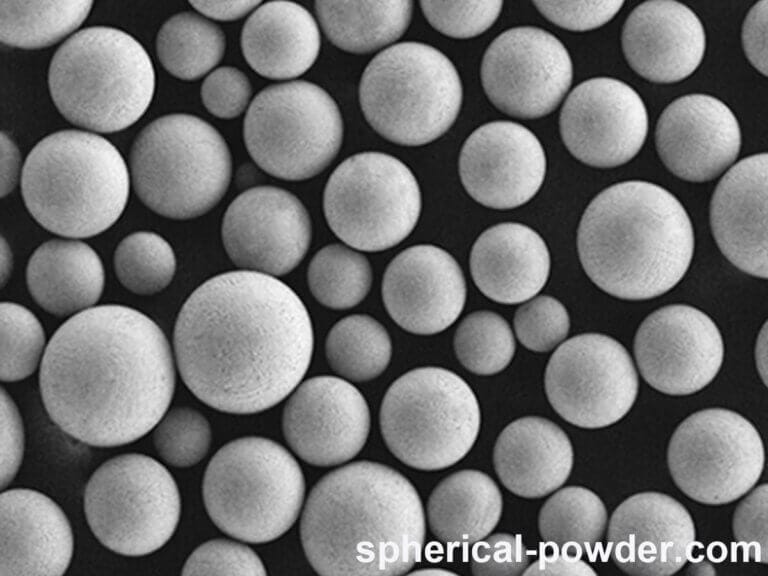

Polvo esférico frente a polvo irregular: ¿cuál es mejor?

| Forma de polvo | Características | Mejor aplicación |

|---|---|---|

| Esférica | Excelente fluidez, empaquetamiento uniforme, baja porosidad | Impresión 3D, AM, LPBF, SLM |

| Irregular | Menor fluidez, mayor porosidad, rentable | Binder Jetting, MIM, Recubrimientos |

Polvos esféricos atomizados por gas se prefieren para fabricación aditivagarantizando mejor adherencia de la capa y rendimiento mecánico.

Descubra nuestros polvos de aleación esféricos personalizables.

Principales proveedores de aleaciones en polvo personalizadas en 2025

Principales fabricantes de polvos de aleación a medida

| Nombre del proveedor | País | Especialización | Métodos de producción | Página web |

|---|---|---|---|---|

| Heeger Materials Inc. | EE.UU | Polvos de aleación a medida | VIGA, PREP, Atomización con gas | Visitar el sitio |

| Höganäs | Suecia | Polvos metálicos | Atomización del agua | N/A |

| Oerlikon Metco | Suiza | Polvos AM para el sector aeroespacial y médico | Atomización de gases | N/A |

| Sandvik | Suecia | Fabricación aditiva | Atomización de gases | N/A |

¿Por qué elegir Heeger Materials para el polvo de aleación a medida?

- Más de 40 años de experiencia en pulvimetalurgia.

- Composiciones de aleación a medida para aplicaciones aeroespaciales, médicas e industriales.

- Polvos atomizados por gas que garantizan una gran pureza y consistencia.

- Precios competitivos y distribución mundial.

En busca de polvos de aleación a medida? Póngase en contacto con Heeger Materials hoy mismo.

Normas de calidad para aleaciones en polvo a medida

Garantizar calidad constante en aleación en polvo personalizada es esencial para rendimiento fiable, repetibilidad y cumplimiento de la normativa industrial. Varios normas internacionales rigen la producción, composición y aplicación de estos polvos para satisfacer requisitos aeroespaciales, médicos e industriales.

Principales normas de calidad del polvo de aleación personalizado

| Estándar | Descripción |

|---|---|

| ASTM F3049 | Norma para caracterización del polvo metálico en la fabricación aditiva. |

| ASTM F3302 | Especificación para polvos metálicos utilizados en procesos de fusión de lecho de polvo (PBF) AM. |

| ISO 52907 | Directrices para control de calidad de los polvos utilizados en la fabricación aditiva. |

| AMS 4999 | Especificación de materiales aeroespaciales para polvos a base de titanio y níquel. |

| ISO 13485 | Sistema de gestión de la calidad de los productos sanitarios para producción de polvo biocompatible. |

| Conformidad RoHS | Garantiza seguridad medioambiental mediante la limitación de sustancias peligrosas. |

¿Por qué elegir polvos de aleación personalizados certificados?

- Garantiza una composición química uniforme - Mantiene propiedades coherentes de los materiales para piezas más resistentes y fiables.

- Tamaño y forma optimizados de las partículas - Crítico para fluidez, imprimibilidad y adhesión de capas en los procesos de AM.

- Alta pureza y bajo contenido de oxígeno - Reduce defectos y mejora el rendimiento final de la pieza.

- Cumplimiento de la normativa aeroespacial y de la normativa médica - Garantiza seguridad y precisión en aplicaciones de alto rendimiento.

En Heeger Materials Inc.fabricamos polvos de aleación a medida que cumplen estrictas normas internacionales de calidadgarantizando materiales de alto rendimiento para industrias exigentes.

Análisis de costes del polvo de aleación personalizado

El precio de aleación en polvo personalizada varía en función de composición, método de producción y demanda de la industria.

Factores que afectan al coste del polvo de aleación personalizado

- Complejidad de la aleación - Exóticos aleaciones de alta entropía (HEA) y superaleaciones son más caros debido a las dificultades de procesamiento.

- Método de producción - Atomización por plasma y PREP (Proceso de Electrodo Rotatorio de Plasma) producir polvos esféricos de mayor calidadaumentando los costes.

- Distribución del tamaño de las partículas (PSD) - Polvos finos (15-45µm) para LPBF son más caro debido a mayores requisitos de precisión.

- Niveles de pureza - Niveles más bajos de oxígeno e impurezas mejorar el rendimiento sino aumentar los costes de producción.

- Oferta y demanda mundiales - Los precios fluctúan en función de disponibilidad de materias primas y tendencias del sector.

Comparación de precios de los polvos de aleación a medida

| Tipo de aleación | Coste ($/kg) | Caso de uso común |

|---|---|---|

| Aleación de titanio a medida | 250-250 - 250-700 | Aeroespacial, implantes médicos |

| Superaleación a base de níquel | 300-300 - 300-900 | Componentes aeroespaciales de alta temperatura |

| Aleación de cobalto y cromo | 200-200 - 200-500 | Implantes médicos, aplicaciones dentales |

| Aleación de alta entropía (HEA) | 500-500 - 500-1,200 | Aeroespacial, defensa, investigación |

| Aleación personalizada a base de tungsteno | 400-400 - 400-1,000 | Blindaje contra las radiaciones, aplicaciones energéticas |

Aleaciones de alto rendimiento como las HEA y las superaleaciones tienden a ser más caros debido a sus propiedades mecánicas avanzadas y a los requisitos de transformación.

Solicite un presupuesto personalizado para pedidos al por mayor de polvo de aleación personalizado.

Métodos de producción de aleaciones en polvo a medida

Diferentes métodos de producción de polvo impact the forma, pureza y coste de las partículas de polvos de aleación a medida.

Comparación de los métodos de producción de polvo

| Método de producción | Forma de las partículas | Pureza | Coste | El mejor caso de uso |

|---|---|---|---|---|

| Atomización de gas (GA) | Esférica | Alta | $$$ | impresión 3D, Aeroespacial |

| Atomización por plasma (PA) | Altamente esférico | Muy alta | $$$$ | Medicina, aeroespacial |

| Atomización del agua (WA) | Irregular | Moderado | $$ | Binder Jetting, MIM |

| PREP (Proceso de Electrodo Rotatorio de Plasma) | Extremadamente esférico | Ultra Alta | $$$$$ | Aplicaciones aeroespaciales y médicas de alto rendimiento |

Atomización con gas y atomización con plasma son los métodos más utilizados para polvo de aleación a medidagarantizando excelente pureza, esfericidad e imprimibilidad.

Heeger Materials Inc. se especializa en polvos de aleación personalizados atomizados por gas y plasmaentregando calidad y consistencia superiores.

Preguntas frecuentes sobre el polvo de aleación personalizado

| Pregunta | Respuesta |

|---|---|

| ¿Cómo puedo pedir un polvo de aleación a medida? | Puede solicitar presupuesto de Heeger Materials Inc. Estamos especializados en composiciones de aleación a medida para aplicaciones específicas. |

| ¿Puedo especificar la distribución granulométrica (PSD) de mi polvo personalizado? | Sí. Ofrecemos 15-45µm para LPBF, 45-75µm para EBM y DED, y 75-150µm para Binder Jetting y MIM. |

| ¿Cuál es la mejor aleación personalizada para aplicaciones aeroespaciales de alta temperatura? | Superaleaciones a base de níquel (Inconel), aleaciones a base de wolframio y aleaciones de alta entropía (HEA). son ideales para entornos extremos. |

| ¿Por qué elegir polvo atomizado por gas en lugar de polvo atomizado por agua? | Polvos atomizados por gas son esféricos, tienen mejor fluidez y ofrecen mayor purezapor lo que son ideales para fabricación aditiva. |

| ¿Dónde puedo comprar polvo de aleación personalizado de alta calidad? | Heeger Materials Inc. proporciona polvos de aleación premium a medida para aplicaciones industriales. |

Conclusión

Polvos de aleación a medida están transformando fabricación avanzadaque permite a las industrias adaptar los materiales a requisitos específicos de rendimiento. Con los avances en pulvimetalurgia y fabricación aditivaahora las empresas pueden crear componentes de alta resistencia, resistentes a la corrosión y térmicamente estables que cumplen normas industriales estrictas.

Para polvo de aleación de alta calidad personalizado, Heeger Materials Inc. ofrece soluciones a medida con polvos esféricos atomizados por gas de gran pureza.

¿Busca polvo de aleación personalizado? Póngase en contacto con nosotros