Renio en polvo 2025: Propiedades, aplicaciones y perspectivas de mercado

Visión general del renio en polvo

Renio en polvo es un metal refractario raro y de alto rendimiento conocido por su punto de fusión excepcionalmente alto (3.180°C), superior arrastrarse y una excelente resistencia a altas temperaturas. Estas propiedades lo convierten en un material esencial en industrias aeroespacial, electrónica, médica y de catalizadores.

Debido a su combinación única de resistencia mecánica, estabilidad térmica y resistencia a la corrosión, renio en polvo se utiliza ampliamente en álabes de turbina, contactos eléctricos, revestimientos y catalizadores para el refinado del petróleo.

En Heeger Materials Inc.Estamos especializados en polvos de renio de gran purezagarantizando rendimiento óptimo para aplicaciones industriales avanzadas.

¿Por qué elegir el renio en polvo?

El polvo de renio es un material crítico en aplicaciones de alto rendimiento que exigen resistencia a temperaturas extremas, durabilidad y excelente conductividad.

Principales ventajas del renio en polvo

- Punto de fusión ultraalto (3.180°C) - Uno de los los puntos de fusión más altos de cualquier metalideal para condiciones extremas.

- Resistencia superior a altas temperaturas - Mantiene integridad mecánica en condiciones de calor extremopor lo que es perfecto para aplicaciones aeroespaciales e industriales.

- Excelente resistencia a la corrosión y al desgaste - Resiste oxidación y ambientes agresivos, garantizando la longevidad.

- Excelente conductividad eléctrica - Utilizado en contactos eléctricos y semiconductores de alto rendimiento.

- Propiedades catalíticas - Imprescindible para tratamiento de hidrocarburos en el refinado de petróleo.

En busca de ¿renio en polvo de gran pureza? Explore la selección de Heeger Materials.

Productos relacionados

Las mejores calidades de renio en polvo para distintas aplicaciones

Los polvos de renio se clasifican en función de pureza, tamaño de las partículas y aplicaciones previstas.

Comparación de las calidades del polvo de renio

| Grado | Pureza (%) | Propiedades clave | Mejores aplicaciones |

|---|---|---|---|

| Renio en polvo de gran pureza | 99.99% | Pureza ultra alta, impurezas mínimas | Semiconductores, electrónica |

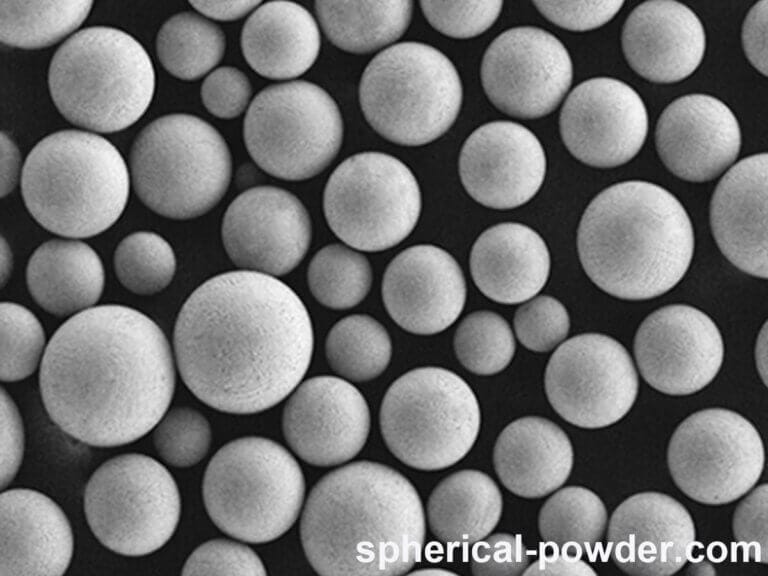

| Polvo esférico de renio | 99.9+% | Alta fluidez, optimizada para la impresión 3D | Fabricación aditiva, aeroespacial |

| Polvo de aleación de renio (Re-W, Re-Mo, Re-Ta) | 99.9+% | Mayor resistencia mecánica y a la oxidación | Superaleaciones, álabes de turbina |

| Renio en polvo de calidad catalizadora | 99.9% | Alta eficacia catalítica, estabilidad química superior | Refinado del petróleo, reacciones de hidrogenación |

Polvo esférico de renio es fundamental para Impresión 3D y sector aeroespacialmientras que renio para catalizadores domina industria petroquímica.

Solicite un presupuesto personalizado de renio en polvo.

Aplicaciones del polvo de renio en la industria

El polvo de renio se utiliza en aplicaciones de alto rendimiento que requiere durabilidad, conductividad y resistencia a la corrosión extremas.

Aplicaciones industriales clave

| Industria | Aplicación | Ventajas |

|---|---|---|

| Aeroespacial y defensa | Palas de turbina de motores a reacción, toberas de cohetes | Estabilidad a altas temperaturas, resistencia a la fluencia |

| Electrónica y semiconductores | Contactos eléctricos, revestimientos de película fina | Conductividad eléctrica y durabilidad superiores |

| Industria petroquímica | Catalizadores para el refinado del petróleo | Muy eficaz en reacciones de hidrogenación |

| Medicina y sanidad | Tubos de rayos X, blindaje contra las radiaciones | Alta densidad, biocompatibilidad |

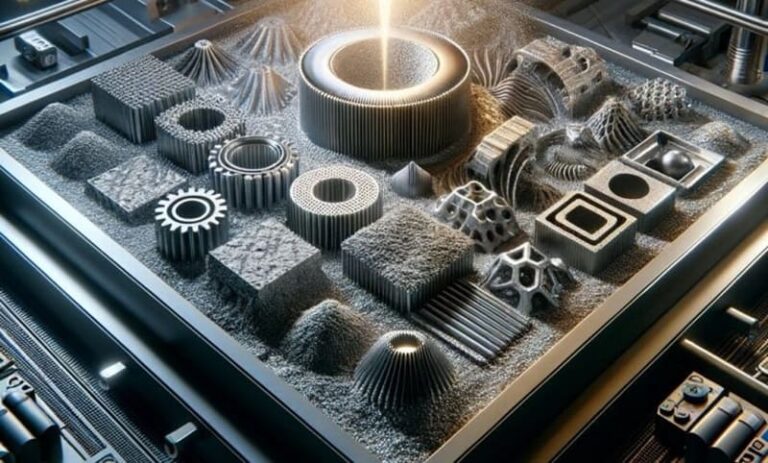

| Fabricación aditiva (AM) | Piezas de alta temperatura impresas en 3D | Geometrías complejas, componentes ligeros |

Con el Creciente demanda de materiales aeroespaciales de alto rendimiento y catalizadores energéticamente eficientes., renio en polvo sigue siendo un material crítico para la innovación.

Descubra nuestros polvos de renio de alto rendimiento.

Tamaño y forma de las partículas de renio en polvo

En distribución del tamaño de las partículas (PSD) y morfología impacto fluidez, comportamiento de sinterización y calidad del producto final en Impresión 3D, electrónica y revestimientos.

Tamaño óptimo de las partículas para aplicaciones de polvo de renio

| Gama de tamaños de partículas | Mejor aplicación |

|---|---|

| 0,5-10 µm | Recubrimientos de alta precisión, catalizadores |

| 10-45 µm | Electrónica, aplicaciones de semiconductores |

| 45-150 µm | Impresión 3D, componentes aeroespaciales |

Polvo de renio esférico frente a irregular: ¿cuál es mejor?

| Forma de polvo | Características | Mejor aplicación |

|---|---|---|

| Esférica | Alta fluidez, empaquetado uniforme, sinterización mejorada | Impresión 3D, aeroespacial, aplicaciones médicas |

| Irregular | Mayor superficie, mayor porosidad | Catalizadores, revestimientos, electrónica |

Polvos esféricos de renio se prefieren para fabricación aditiva y sector aeroespacialmientras que polvos irregulares se utilizan en catalizadores y revestimientos.

Explore nuestros polvos de renio optimizados.

Principales proveedores de renio en polvo en 2025

Encontrar un proveedor de confianza es esencial para calidad, pureza y rendimiento constantes en aplicaciones del renio.

Principales proveedores de renio en polvo

| Nombre del proveedor | País | Especialización | Métodos de producción | Página web |

|---|---|---|---|---|

| Heeger Materials Inc. | EE.UU | Renio en polvo | VIGA, PREP, Atomización con gas | Visitar el sitio |

| H.C. Starck | Alemania | Polvos de metales refractarios | Hidruro-Dehidruro, Atomización por plasma | N/A |

| Elementos americanos | EE.UU | Renio de gran pureza | Pulvimetalurgia | N/A |

| Grupo Plansee | Austria | Productos de renio de alto rendimiento | Pulvimetalurgia | N/A |

Heeger Materials Inc. ofrece polvos de renio a medida para cumplir los demandas de las industrias aeroespacial, electrónica y de fabricación aditiva.

Póngase en contacto con Heeger Materials para obtener polvos de renio de primera calidad.

Normas de calidad para el renio en polvo

Garantizar renio de gran pureza en polvo es crucial para aplicaciones aeroespaciales, electrónicas, catalizadoras y médicas. Varios normas internacionales regular la composición, el tamaño de las partículas y la calidad de los polvos de renio para satisfacer requisitos industriales y tecnológicos.

Principales normas de calidad del renio en polvo

| Estándar | Descripción |

|---|---|

| ASTM B818 | Especificación para pureza y propiedades del renio metálico en polvo. |

| ISO 17270 | Norma internacional para renio y aleaciones de renio utilizadas en aplicaciones aeroespaciales. |

| AMS 7891 | Especificación de materiales aeroespaciales para superaleaciones que contienen renio. |

| MIL-R-27483 | Norma militar estadounidense para renio utilizado en aplicaciones de alta temperatura. |

| Conformidad RoHS | Garantiza seguridad medioambiental mediante la limitación de sustancias peligrosas. |

¿Por qué elegir el renio certificado en polvo?

- Garantiza una pureza y un rendimiento constantes - Garantías estabilidad a altas temperaturas y resistencia mecánica.

- Crítico para el sector aeroespacial y de defensa - Reuniones normas estrictas para entornos extremos.

- Optimizado para electrónica y catalizadores - Garantiza conductividad fiable y actividad catalítica.

- Cumplimiento global - Se adhiere a normas industriales internacionales para aplicaciones de alta tecnología.

En Heeger Materials Inc.proporcionamos polvos de renio de gran pureza que cumplan Normas ASTM, ISO y AMSgarantizando rendimiento y fiabilidad superiores.

Análisis de costes del polvo de renio

El precio de renio en polvo está influenciada por disponibilidad de materias primas, complejidad de la producción y demanda de la industria. Desde el renio es uno de los elementos más raros de la Tierrasu coste es mayor en comparación con otros metales refractarios.

Factores que influyen en el coste del renio en polvo

- Pureza y calidad - El renio de pureza ultra alta (99,99%) para semiconductores es más caro que el renio de grado catalizador (99,9%).

- Método de producción - Los polvos de renio atomizados por gas y procesados por plasma son más costosos que los polvos molidos mecánicamente..

- Distribución del tamaño de las partículas (PSD) - Los polvos más finos (0,5-10 µm) para catalizadores y revestimientos requieren un procesamiento avanzado, lo que aumenta los costes..

- Escasez de materias primas - El renio se extrae principalmente de la molibdenita, por lo que su suministro depende en gran medida de la producción de molibdeno..

- Demanda del mercado y tendencias del sector - Los precios fluctúan en función de evolución de los sectores aeroespacial, energético y electrónico.

Comparación de precios de las calidades de renio en polvo

| Tipo de polvo de renio | Coste ($/kg) | Caso de uso común |

|---|---|---|

| Renio en polvo de calidad catalizadora | 3,000-3,000 - 3,000-7,000 | Refinado petroquímico, reacciones de hidrogenación |

| Polvo esférico de renio (grado AM) | 5,000-5,000 - 5,000-15,000 | Impresión 3D, componentes aeroespaciales |

| Renio en polvo de calidad médica | 8,000-8,000 - 8,000-20,000 | Protección contra las radiaciones, productos sanitarios |

| Polvo de renio de pureza ultra alta (99,99%) | 10,000-10,000 - 10,000-25,000 | Semiconductores, superconductores |

| Polvo de aleación de renio (Re-W, Re-Ta, Re-Mo) | 6,000-6,000 - 6,000-18,000 | Superaleaciones, álabes de turbina |

Renio para catalizadores domina el sector del refinado de petróleomientras que polvos esféricos y de pureza ultra alta de renio son esenciales para aplicaciones aeroespaciales avanzadas y semiconductores.

Solicite un presupuesto de precios al por mayor de renio en polvo.

Métodos de producción del polvo de renio

Diferentes técnicas de producción de polvo impacto morfología, pureza y coste de las partículaspor lo que es esencial seleccionar el método adecuado para la aplicación prevista.

Comparación de los métodos de producción de polvo de renio

| Método de producción | Forma de las partículas | Pureza | Coste | El mejor caso de uso |

|---|---|---|---|---|

| Reducción de hidrógeno | Irregular | Alta | $$ | Catalizadores, revestimientos |

| Atomización de gas (GA) | Esférica | Muy alta | $$$ | Impresión 3D, piezas aeroespaciales |

| Atomización por plasma (PA) | Altamente esférico | Ultra Alta | $$$$ | Aplicaciones médicas, AM de alta precisión |

| Fresado mecánico | En forma de escamas | Moderado | $$ | Recubrimientos por pulverización, aplicaciones de sinterización |

Polvos de renio atomizados con gas y tratados con plasma se prefieren para aplicaciones de alto rendimientogarantizando fluidez e imprimibilidad superiores.

Heeger Materials Inc. se especializa en polvos de renio de gran pureza atomizados por gas para aplicaciones electrónicas, aeroespaciales y médicas.

Preguntas frecuentes sobre el renio en polvo

| Pregunta | Respuesta |

|---|---|

| ¿Para qué se utiliza el renio en polvo? | Se utiliza en álabes de turbina, semiconductores, catalizadores, revestimientos aeroespaciales y aplicaciones médicas.. |

| ¿Por qué es valioso el renio en el sector aeroespacial? | El renio proporciona excepcional resistencia a altas temperaturas y a la fluenciapor lo que es ideal para motores a reacción y toberas de cohetes. |

| ¿Cuál es el mejor polvo de renio para impresión 3D? | Polvo esférico de renio (45-150µm) es ideal para fabricación aditiva debido a su excelente fluidez y sinterización uniforme. |

| ¿Cómo se compara el renio con el wolframio para aplicaciones de alta temperatura? | El renio es más dúctil y resistente a la oxidación que el wolframio.por lo que es superior para aplicaciones para entornos extremos. |

| ¿Dónde puedo comprar renio en polvo de gran pureza? | Heeger Materials Inc. proporciona polvo de renio para aplicaciones industriales. |

Conclusión

Renio en polvo es un material crítico para las industrias de alta tecnología, ofreciendo estabilidad a altas temperaturas, conductividad y eficacia catalítica inigualables para aeroespacial, electrónica, energía y fabricación aditiva.

Para polvos de renio de alta calidad, Heeger Materials Inc. proporciona soluciones a medida con polvos esféricos atomizados por gas de gran pureza.

¿Busca renio en polvo de primera calidad? Póngase en contacto con nosotros