Impresión 3D metálica 2025: El futuro de la fabricación aditiva

Visión general de la impresión 3D en metal

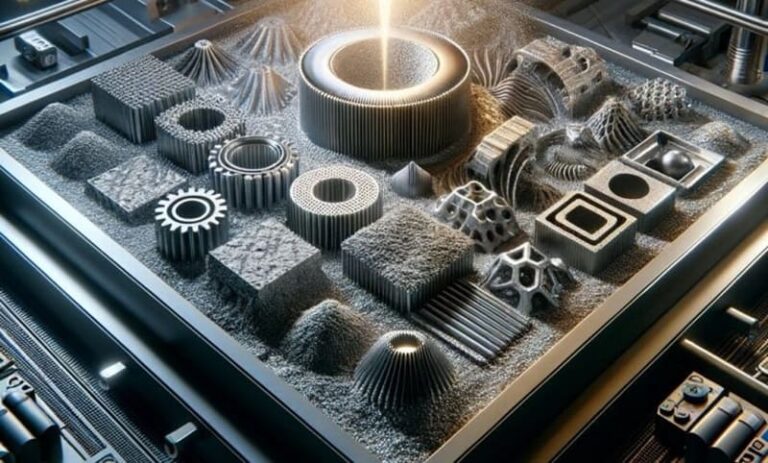

Impresión 3D en metaltambién conocido como fabricación aditiva (AM) de metalesestá revolucionando las industrias al permitir la producción de piezas metálicas complejas de alto rendimiento con menor desperdicio de material, mayor eficacia y mayor libertad de diseño. Esta tecnología se utiliza ampliamente en aplicaciones aeroespaciales, médicas, automovilísticas e industriales donde los métodos de fabricación tradicionales se quedan cortos.

Utilizando polvos metálicos avanzadosLa impresión metálica en 3D permite producir componentes ligeros, de alta resistencia y termorresistenteslo que la convierte en un motor clave de fabricación de nueva generación.

En Heeger Materials Inc.Estamos especializados en polvos metálicos de alta calidad optimizado para varios impresión 3D procesagarantizando una imprimibilidad y un rendimiento mecánico superiores.

¿Por qué elegir la impresión 3D sobre metal?

La impresión 3D en metal ofrece ventajas incomparables sobre la fabricación tradicional, por lo que es ideal para creación de prototipos, producción y personalización.

Principales ventajas de la impresión 3D en metal

- Geometrías complejas y estructuras ligeras - Activa diseños imposibles con el mecanizado convencional.

- Reducción del desperdicio de material - A diferencia de fabricación sustractivaimpresión 3D en metal minimiza los residuos utilizando sólo el material necesario.

- Propiedades mecánicas superiores - Exposición de piezas alta resistencia, durabilidad y resistencia al calor.

- Personalización y producción rápida - Ideal para series de producción de bajo volumen y alto valor.

- Cadenas de suministro eficientes - Reduce plazos y costes logísticos.

En busca de ¿polvos metálicos de alto rendimiento para impresión 3D? Explore la selección de Heeger Materials.

Productos relacionados

-

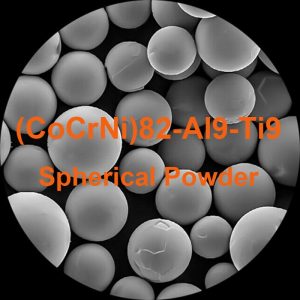

Polvo esférico de aleación de alta entropía (CoCrNi)82-Al9-Ti9 - (CoCrNi)82-Al9-Ti9 HEA - Fabricación aditiva - Impresión 3D

-

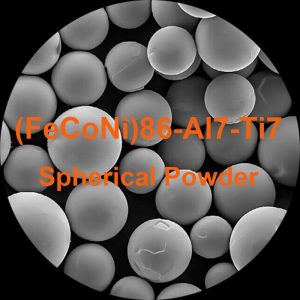

Polvo esférico de aleación de alta entropía (FeCoNi)86-Al7-Ti7 - (FeCoNi)86-Al7-Ti7 HEA - Fabricación aditiva - Impresión 3D

-

(Ni3.5Co3Cr1.5)90-Al5-Ti5 Polvo esférico de aleación de alta entropía - (Ni3.5Co3Cr1.5)90-Al5-Ti5 HEA - Fabricación aditiva - Impresión 3D

-

Polvo esférico de aleación de alta entropía Al-Co-Cr-Fe-Mo - Al-Co-Cr-Fe-Mo HEA - Fabricación aditiva - Impresión 3D

Los mejores polvos metálicos para impresión 3D

Selección del polvo metálico adecuado es crucial para imprimibilidad, propiedades mecánicas y rendimiento final de la pieza.

Comparación de polvos metálicos para impresión 3D

| Polvo metálico | Propiedades clave | Mejores aplicaciones |

|---|---|---|

| Aleaciones de titanio (Ti6Al4V) | Ligero, de alta resistencia, biocompatible | Aeroespacial, implantes médicos |

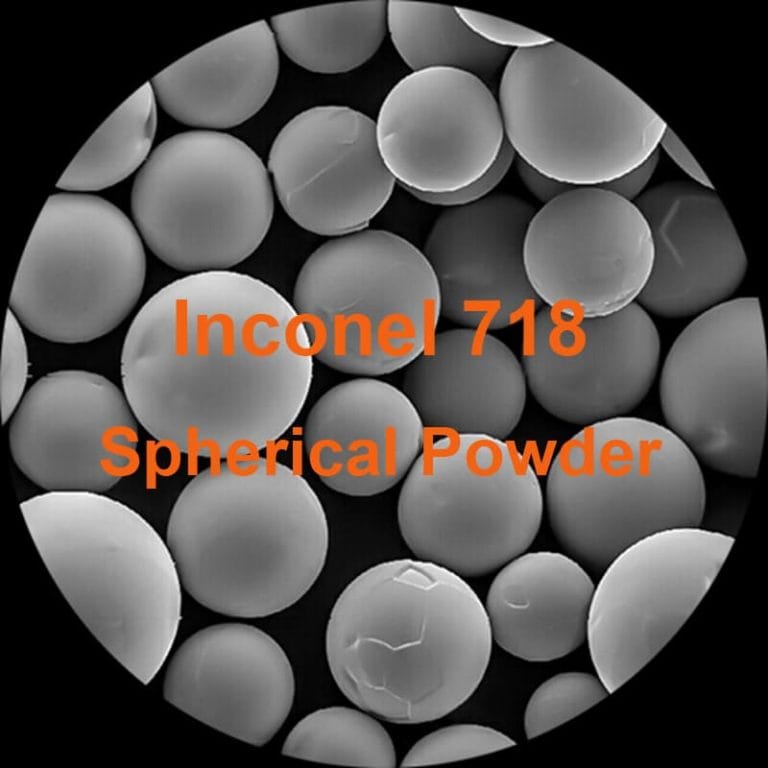

| Aleaciones a base de níquel (Inconel 625, 718) | Resistencia a altas temperaturas, resistencia a la corrosión | Aeroespacial, energía, automoción |

| Aleaciones a base de cobalto (estelita, CoCrMo) | Resistencia al desgaste y a la oxidación | Herramientas médicas, dentales e industriales |

| Acero inoxidable (316L, 17-4PH) | Alta resistencia, resistencia a la corrosión | Industria, marina, medicina |

| Aleaciones de aluminio (AlSi10Mg, Al7075) | Ligero, buena conductividad térmica | Automoción, aeroespacial |

| Cobre y aleaciones de cobre | Alta conductividad térmica y eléctrica | Electrónica, intercambiadores de calor |

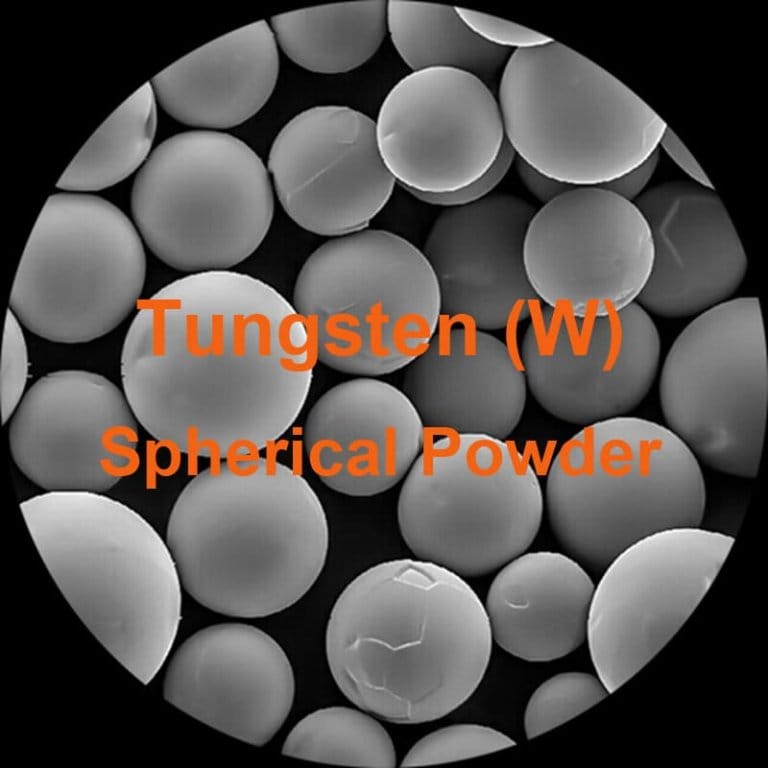

| Tungsteno y metales refractarios | Alta densidad, resistencia extrema al calor | Defensa, nuclear, aeroespacial |

Aleaciones a base de níquel y polvos de titanio se prefieren para aplicaciones de alto rendimientomientras que polvos de acero inoxidable y aluminio oferta soluciones rentables.

Solicite un presupuesto personalizado de polvos metálicos para impresión 3D.

Tecnologías de impresión 3D en metal

Diferentes Tecnologías de impresión 3D se utilizan para fabricación aditiva de metalescada uno con un ventajas y compatibilidad de materiales.

Comparación de los procesos de impresión 3D en metal

| Método de impresión 3D | Tipo de proceso | Los mejores materiales | Principales ventajas |

|---|---|---|---|

| Fusión láser en lecho de polvo (LPBF/SLM/DMLS) | En polvo | Titanio, níquel, acero inoxidable | Alta precisión, detalles finos |

| Fusión por haz de electrones (EBM) | En polvo | Titanio, cromo-cobalto | Procesado a alta temperatura, producción a granel |

| Chorro aglomerante | En polvo | Acero inoxidable, bronce | Producción rentable a gran escala |

| Deposición de energía dirigida (DED/LMD) | Alambre o polvo | Níquel, titanio, acero inoxidable | Reparación y fabricación híbrida |

| Chorro de ligante metálico | En polvo | Acero inoxidable, cobre | Producción de bajo coste y gran volumen |

LPBF (SLM/DMLS) y EBM son los más utilizados para aplicaciones aeroespaciales y médicas de alto rendimientomientras que Chorro aglomerante y DED son ideales para producción en serie rentable.

Encuentre el mejor polvo metálico para su proceso de impresión 3D.

Aplicaciones de la impresión 3D metálica en la industria

La impresión metálica en 3D está transformando las industrias componentes ligeros, de alto rendimiento y rentables.

Aplicaciones industriales clave

| Industria | Aplicación | Ventajas |

|---|---|---|

| Aeroespacial y defensa | Componentes estructurales ligeros, álabes de turbina | Alto rendimiento, peso reducido |

| Automoción | Piezas de motor a medida, componentes ligeros | Mayor eficiencia del combustible, prototipado rápido |

| Medicina y odontología | Implantes y prótesis específicos para cada paciente | Biocompatibilidad, fabricación de precisión |

| Energía y generación de electricidad | Intercambiadores de calor, turbinas de gas | Resistencia a altas temperaturas, durabilidad |

| Herramientas industriales | Moldes, matrices, revestimientos resistentes al desgaste | Mayor vida útil de la herramienta, ahorro de costes |

Con el auge de vehículos eléctricos (VE) y componentes aeroespaciales avanzados, la impresión 3D metálica impulsa las innovaciones de fabricación de nueva generación.

Descubra nuestros polvos metálicos de alto rendimiento para impresión 3D.

Normas de calidad para polvos metálicos de impresión 3D

Para garantizar impresión fiable y repetibleLos polvos metálicos deben cumplir estrictas normas de calidad.

Principales normas de calidad para polvos metálicos de impresión 3D

| Estándar | Descripción |

|---|---|

| ASTM F3049 | Norma para caracterización del polvo metálico en la fabricación aditiva. |

| ASTM F3302 | Especificación para polvos metálicos utilizados en procesos de fusión de lecho de polvo (PBF) AM. |

| ISO 52907 | Directrices para control de calidad de los polvos utilizados en la fabricación aditiva. |

| AMS 4999 | Especificación de materiales aeroespaciales para níquel y titanio en polvo. |

| Conformidad RoHS | Garantiza seguridad medioambiental mediante la limitación de sustancias peligrosas. |

En Heeger Materials Inc.fabricamos polvos metálicos de gran pureza que cumplan Normas ASTM, ISO y AMSgarantizando excelente imprimibilidad y rendimiento mecánico.

Análisis de costes de los polvos metálicos para impresión 3D

El coste de polvos metálicos para impresión 3D varía en función de composición del material, método de producción y demanda de la industria. Aleaciones de alto rendimiento como titanio, superaleaciones a base de níquel y polvos a base de cobalto tienden a ser más caro debido a su propiedades mecánicas avanzadas y requisitos de transformación.

Factores que afectan al coste del polvo de impresión 3D metálico

- Composición del material - Las aleaciones exóticas (titanio, inconel, cromo-cobalto) son más caras que el acero inoxidable o el aluminio en polvo..

- Método de producción - La atomización con gas y la atomización con plasma producen polvos muy esféricos y de gran pureza, lo que aumenta los costes.

- Distribución del tamaño de las partículas (PSD) - Los polvos más finos (15-45µm) para LPBF son más caros debido a los requisitos de precisión.

- Pureza y contenido de oxígeno - Los niveles más bajos de oxígeno mejoran las propiedades mecánicas pero aumentan los costes de producción.

- Oferta y demanda del mercado - Los precios fluctúan en función de disponibilidad de materias primas, tendencias del sector y factores geopolíticos.

Comparación de precios de los polvos metálicos para impresión 3D

| Tipo de polvo metálico | Coste ($/kg) | Aplicaciones comunes |

|---|---|---|

| Aleación de titanio (Ti6Al4V) | 300-300 - 300-700 | Aeroespacial, implantes médicos |

| Superaleaciones a base de níquel (Inconel 625, 718) | 350-350 - 350-900 | Componentes aeroespaciales de alta temperatura |

| Aleación de cobalto y cromo (CoCrMo) | 250-250 – 250-600 | Implantes médicos, aplicaciones dentales |

| Acero inoxidable (316L, 17-4PH) | 80-80 - 80-250 | Industria, marina, medicina |

| Aleación de aluminio (AlSi10Mg, Al7075) | 80-80 - 80-250 | Automoción, aeroespacial |

| Cobre y aleaciones de cobre | 100-100 - 100-500 | Electrónica, intercambiadores de calor |

| Polvos de tungsteno y metales refractarios | 400-400 - 400-1,200 | Defensa, nuclear, aeroespacial |

Titanio y aleaciones a base de níquel se prefieren para aplicaciones de alto rendimientomientras que polvos de acero inoxidable y aluminio oferta soluciones rentables para uso industrial.

Solicite un presupuesto personalizado para pedidos al por mayor.

Métodos de producción de polvos metálicos para impresión 3D

Diferentes técnicas de producción de polvo impact the forma, pureza y coste de las partículas de polvos metálicos para impresión 3D.

Comparación de los métodos de producción de polvo

| Método de producción | Forma de las partículas | Pureza | Coste | El mejor caso de uso |

|---|---|---|---|---|

| Atomización de gas (GA) | Esférica | Alta | $$$ | LPBF, EBM, Chorro de ligante |

| Atomización por plasma (PA) | Altamente esférico | Muy alta | $$$$ | Aplicaciones médicas y aeroespaciales |

| Atomización del agua (WA) | Irregular | Moderado | $$ | Binder Jetting, MIM |

| Proceso de electrodos rotativos de plasma (PREP) | Extremadamente esférico | Ultra Alta | $$$$$ | Aplicaciones aeroespaciales y médicas de alto rendimiento |

Atomización con gas y atomización con plasma son los métodos más utilizados para polvos metálicos de impresión 3D de alta calidadgarantizando excelente pureza, esfericidad e imprimibilidad.

Heeger Materials Inc. se especializa en polvos metálicos atomizados por gas y plasmaentregando calidad y consistencia superiores.

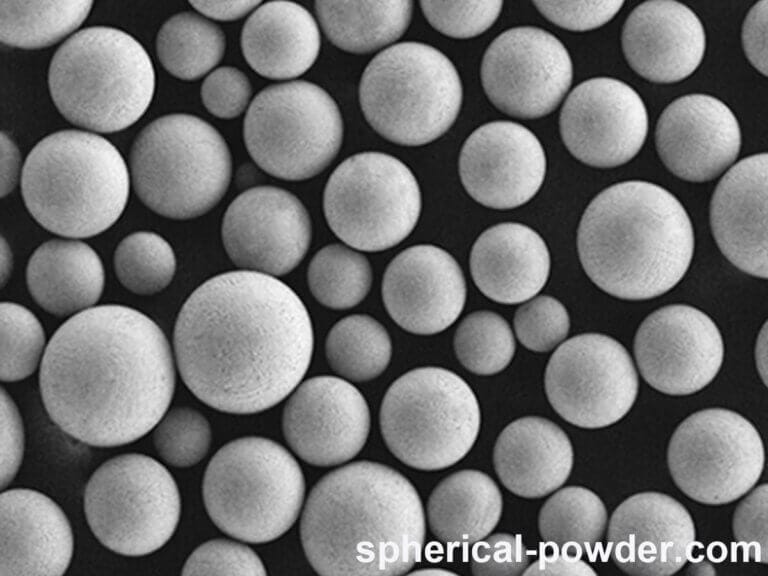

Tamaño y forma de las partículas en polvos metálicos para impresión 3D

En distribución del tamaño de las partículas (PSD) y morfología desempeñan un papel clave en fluidez del polvo, densidad de empaquetado y calidad de la pieza final en procesos de impresión 3D en metal.

Tamaño óptimo de las partículas para aplicaciones de impresión 3D en metal

| Gama de tamaños de partículas | Mejor aplicación |

|---|---|

| 15-45 µm | Fusión láser en lecho de polvo (LPBF, SLM, DMLS) |

| 45-75 µm | Fusión por haz de electrones (EBM), deposición de energía dirigida (DED) |

| 75-150 µm | Inyección de aglomerante, moldeo por inyección de metal (MIM) |

Polvo esférico frente a polvo irregular: ¿cuál es mejor?

| Forma de polvo | Características | Mejor aplicación |

|---|---|---|

| Esférica | Excelente fluidez, empaquetado uniforme, alta imprimibilidad | LPBF, EBM, Chorro de ligante |

| Irregular | Menor fluidez, acabado superficial más rugoso, menor coste | Binder Jetting, MIM |

Polvos esféricos se prefieren para fabricación aditiva de metalesgarantizando mejor fluidez, estratificación uniforme y defectos mínimos.

Descubra nuestros polvos metálicos esféricos de alta calidad.

Principales proveedores en 2025

Encontrar un proveedor fiable es crucial para calidad, repetibilidad y rendimiento constantes en impresión metálica en 3D.

Principales proveedores

| Nombre del proveedor | País | Especialización | Métodos de producción | Página web |

|---|---|---|---|---|

| Heeger Materials Inc. | EE.UU | Polvos metálicos para impresión 3D | VIGA, PREP, Atomización con gas | Visitar el sitio |

| Höganäs | Suecia | Polvos metálicos para AM | Atomización del agua | N/A |

| Oerlikon Metco | Suiza | Polvos de impresión 3D aeroespacial e industrial | Atomización de gases | N/A |

| Sandvik | Suecia | Recubrimientos duros y polvos antidesgaste | Atomización de gases | N/A |

En busca de polvos metálicos de alto rendimiento para impresión 3D? Póngase en contacto con Heeger Materials hoy mismo..

PREGUNTAS FRECUENTES

| Pregunta | Respuesta |

|---|---|

| ¿Para qué se utiliza la impresión 3D sobre metal? | Se utiliza para aplicaciones aeroespaciales, médicas, automovilísticas e industriales que requiere piezas metálicas de alto rendimiento. |

| ¿Cuál es el mejor metal para la impresión 3D de piezas aeroespaciales? | Aleaciones de titanio (Ti6Al4V) y superaleaciones a base de níquel (Inconel 625, 718) se prefieren para aplicaciones de alta temperatura y ligereza. |

| ¿Qué método de impresión 3D es mejor para las piezas metálicas? | Fusión en lecho de polvo por láser (LPBF) y fusión por haz de electrones (EBM) oferta alta precisión y excelentes propiedades mecánicas. |

| ¿Cuál es el tamaño típico de las partículas de los polvos metálicos para impresión 3D? | 15-45 µm para LPBF, 45-75 µm para EBM y 75-150 µm para Binder Jetting. |

| ¿Dónde puedo comprar polvo metálico de alta calidad para impresión 3D? | Heeger Materials Inc. proporciona polvos metálicos para fabricación aditiva. |

Conclusión

Impresión 3D en metal está revolucionando fabricación en todos los sectorespermitiendo ligereza, alta resistencia y geometrías complejas que los métodos tradicionales no pueden conseguir.

Para polvos metálicos de impresión 3D de alta calidad, Heeger Materials Inc. proporciona soluciones a medida con polvos esféricos atomizados por gas de gran pureza.

¿Busca polvo de impresión 3D metálico de alta calidad? Póngase en contacto con nosotros

.jpg)