Impression 3D sur métal 2025 : L'avenir de la fabrication additive

Vue d'ensemble de l'impression 3D sur métal

Impression 3D de métauxégalement connu sous le nom de la fabrication additive métallique (AM)L'innovation technologique révolutionne les industries en permettant la production de produits de haute qualité. pièces métalliques complexes et performantes avec réduction des déchets de matériaux, amélioration de l'efficacité et de la liberté de conception. Cette technologie est largement utilisée dans applications aérospatiales, médicales, automobiles et industrielles là où les méthodes de fabrication traditionnelles ne suffisent pas.

En utilisant poudres métalliques avancéesL'impression 3D de métaux permet de produire des des composants légers, très résistants et résistants à la chaleurce qui en fait un moteur essentiel de la croissance de l'économie européenne. fabrication de nouvelle génération.

Au Heeger Materials Inc.Nous sommes spécialisés dans poudres métalliques de haute qualité optimisé pour divers impression 3D processusgarantissant une imprimabilité et des performances mécaniques supérieures.

Pourquoi choisir l'impression 3D sur métal ?

L'impression 3D sur métal offre des avantages inégalés par rapport à la fabrication traditionnelle, ce qui en fait la solution idéale pour prototypage, production et personnalisation.

Principaux avantages de l'impression 3D de métaux

- Géométries complexes et structures légères - Active des conceptions impossibles à réaliser avec l'usinage conventionnel.

- Réduction des déchets matériels - Contrairement à la fabrication soustractiveImpression 3D, impression 3D de métaux minimise les déchets en n'utilisant que le matériel nécessaire.

- Propriétés mécaniques supérieures - Exposition de pièces grande solidité, durabilité et résistance à la chaleur.

- Personnalisation et production rapide - Idéal pour des séries de production de faible volume et de grande valeur.

- Des chaînes d'approvisionnement efficaces - Réduit les délais et les coûts logistiques.

À la recherche de poudres métalliques haute performance pour l'impression 3D ? Découvrez la sélection de Heeger Materials.

Produits apparentés

-

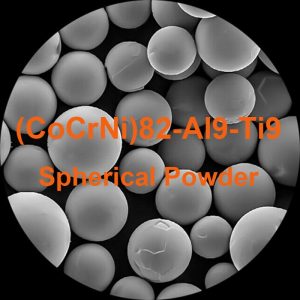

Poudre sphérique d'alliage à haute entropie (CoCrNi)82-Al9-Ti9 - (CoCrNi)82-Al9-Ti9 HEA - Fabrication additive - Impression 3D

-

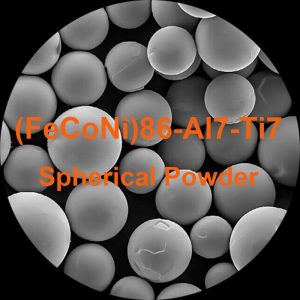

Poudre sphérique d'alliage à haute entropie (FeCoNi)86-Al7-Ti7 - (FeCoNi)86-Al7-Ti7 HEA - Fabrication additive - Impression 3D

-

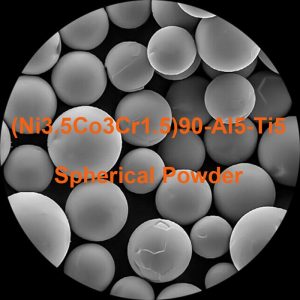

(Ni3.5Co3Cr1.5)90-Al5-Ti5 High-entropy Alloy Spherical Powder - (Ni3.5Co3Cr1.5)90-Al5-Ti5 HEA - Fabrication additive - Impression 3D

-

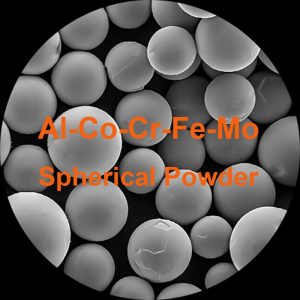

Poudre sphérique d'alliage Al-Co-Cr-Fe-Mo à haute entropie - Al-Co-Cr-Fe-Mo HEA - Fabrication additive - Impression 3D

Les meilleures poudres métalliques pour l'impression 3D

Sélection de la poudre métallique droite est cruciale pour l'imprimabilité, les propriétés mécaniques et la performance de la pièce finale.

Comparaison des poudres métalliques pour l'impression 3D

| Poudre métallique | Propriétés principales | Meilleures applications |

|---|---|---|

| Alliages de titane (Ti6Al4V) | Léger, très résistant, biocompatible | Aérospatiale, implants médicaux |

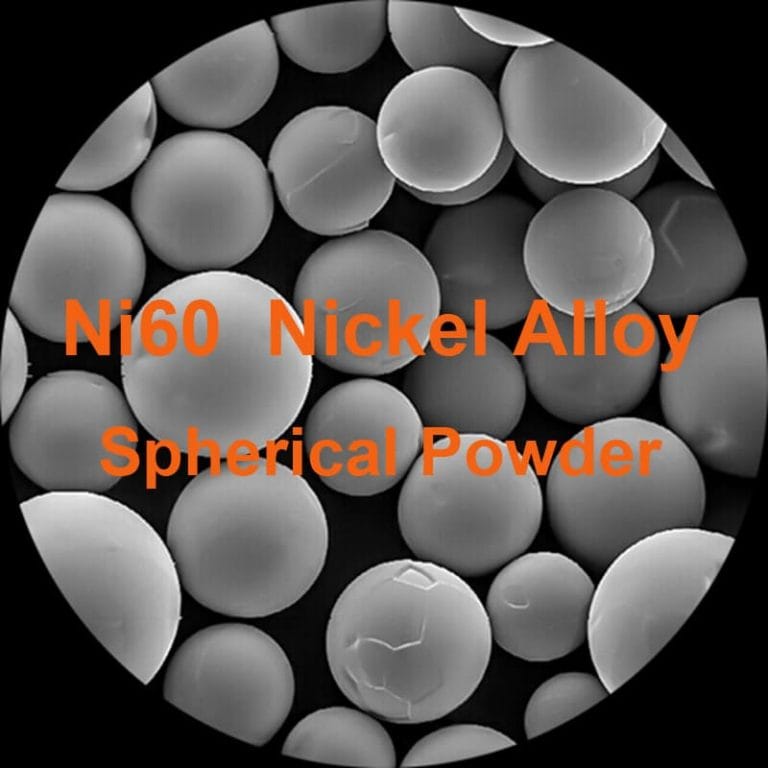

| Alliages à base de nickel (Inconel 625, 718) | Résistance aux hautes températures, résistance à la corrosion | Aérospatiale, énergie, automobile |

| Alliages à base de cobalt (Stellite, CoCrMo) | Résistance à l'usure et à l'oxydation | Outillage médical, dentaire et industriel |

| Acier inoxydable (316L, 17-4PH) | Haute résistance, résistance à la corrosion | Industrie, marine, médecine |

| Alliages d'aluminium (AlSi10Mg, Al7075) | Léger, bonne conductivité thermique | Automobile, aérospatiale |

| Cuivre et alliages de cuivre | Conductivité thermique et électrique élevée | Électronique, échangeurs de chaleur |

| Tungstène et métaux réfractaires | Haute densité, résistance extrême à la chaleur | Défense, nucléaire, aérospatiale |

Alliages à base de nickel et poudres de titane sont préférés pour applications de haute performance, tandis que poudres d'acier inoxydable et d'aluminium offrir des solutions rentables.

Demande de devis personnalisé pour les poudres d'impression 3D de métaux.

Technologies d'impression 3D sur métal

Différents Technologies d'impression 3D sont utilisés pour fabrication additive métallique, chacun ayant son propre avantages et compatibilité des matériaux.

Comparaison des procédés d'impression 3D de métaux

| Méthode d'impression 3D | Type de processus | Les meilleurs matériaux | Principaux avantages |

|---|---|---|---|

| Fusion laser sur lit de poudre (LPBF/SLM/DMLS) | A base de poudre | Titane, nickel, acier inoxydable | Haute précision, détails fins |

| Fusion par faisceau d'électrons (EBM) | A base de poudre | Titane, Cobalt-Chrome | Traitement à haute température, production en vrac |

| Jetting de liant | A base de poudre | Acier inoxydable, bronze | Production rentable à grande échelle |

| Dépôt d'énergie dirigée (DED/LMD) | A base de fil ou de poudre | Nickel, titane, acier inoxydable | Réparation et fabrication d'hybrides |

| Jetting de liant métallique | A base de poudre | Acier inoxydable, cuivre | Production à faible coût et en grande quantité |

LPBF (SLM/DMLS) et EBM sont les plus utilisés pour les applications aérospatiales et médicales de haute performance, tandis que Jets de liant et DED sont idéales pour une production de masse rentable.

Trouvez la meilleure poudre métallique pour votre processus d'impression 3D.

Applications de l'impression 3D de métaux dans l'industrie

L'impression 3D de métaux transforme les industries en permettant des composants légers, performants et rentables.

Applications industrielles clés

| L'industrie | Application | Avantages |

|---|---|---|

| Aérospatiale et défense | Composants structurels légers, pales de turbines | Haute performance, poids réduit |

| Automobile | Pièces de moteur sur mesure, composants légers | Amélioration de l'efficacité énergétique, prototypage rapide |

| Médical et dentaire | Implants et prothèses spécifiques au patient | Biocompatibilité, fabrication de précision |

| Énergie et production d'électricité | Échangeurs de chaleur, turbines à gaz | Résistance aux hautes températures, durabilité |

| Outillage industriel | Moules, matrices, revêtements résistants à l'usure | Prolongation de la durée de vie de l'outil, réduction des coûts |

Avec l'essor des véhicules électriques (VE) et composants aérospatiaux avancés, L'impression 3D de métaux est à l'origine des innovations de la prochaine génération dans le domaine de la fabrication.

Découvrez nos poudres d'impression 3D métalliques haute performance.

Normes de qualité pour les poudres d'impression 3D de métaux

Veiller à ce que impression fiable et reproductibleLes poudres métalliques doivent être conformes à des normes de qualité strictes.

Principales normes de qualité pour les poudres d'impression 3D de métaux

| Standard | Description |

|---|---|

| ASTM F3049 | Norme pour les caractérisation des poudres métalliques dans la fabrication additive. |

| ASTM F3302 | Spécification pour les poudres métalliques utilisées dans les procédés AM de fusion sur lit de poudre (PBF). |

| ISO 52907 | Lignes directrices pour le contrôle de la qualité des poudres utilisées dans la fabrication additive. |

| AMS 4999 | Spécification des matériaux aérospatiaux pour poudres de nickel et de titane. |

| Conformité RoHS | Veille la sécurité environnementale en limitant les substances dangereuses. |

Au Heeger Materials Inc.nous fabriquons poudres métalliques de haute pureté qui sont conformes aux Normes ASTM, ISO et AMS, en veillant à ce que excellente imprimabilité et performances mécaniques.

Analyse des coûts des poudres d'impression 3D de métaux

Le coût de la poudres métalliques pour l'impression 3D varie en fonction de composition du matériau, méthode de production et demande de l'industrie. Les alliages à haute performance tels que poudres de titane, de superalliages à base de nickel et de cobalt tendent à être plus cher en raison de leur propriétés mécaniques avancées et exigences en matière de traitement.

Facteurs influençant le coût de la poudre d'impression 3D de métaux

- Composition du matériau - Les alliages exotiques (titane, inconel, cobalt-chrome) sont plus chers que les poudres d'acier inoxydable ou d'aluminium..

- Méthode de production - L'atomisation au gaz et l'atomisation au plasma produisent des poudres très sphériques et de grande pureté, ce qui augmente les coûts..

- Distribution de la taille des particules (PSD) - Les poudres plus fines (15-45µm) pour le LPBF sont plus chères en raison des exigences de précision..

- Pureté et teneur en oxygène - Des teneurs en oxygène plus faibles améliorent les propriétés mécaniques mais augmentent les coûts de production..

- Offre et demande du marché - Les prix fluctuent en fonction la disponibilité des matières premières, les tendances de l'industrie et les facteurs géopolitiques.

Comparaison des prix des poudres d'impression 3D de métaux

| Type de poudre métallique | Coût ($/kg) | Applications courantes |

|---|---|---|

| Alliage de titane (Ti6Al4V) | 300-300 - 300-700 | Aérospatiale, implants médicaux |

| Superalliage à base de nickel (Inconel 625, 718) | 350-350 - 350-900 | Composants aérospatiaux à haute température |

| Alliage cobalt-chrome (CoCrMo) | 250-250 – ; 250-600 | Implants médicaux, applications dentaires |

| Acier inoxydable (316L, 17-4PH) | 80-80 - 80-250 | Industrie, marine, médecine |

| Alliage d'aluminium (AlSi10Mg, Al7075) | 80-80 - 80-250 | Automobile, aérospatiale |

| Cuivre et alliages de cuivre | 100-100 - 100-500 | Électronique, échangeurs de chaleur |

| Poudres de tungstène et de métaux réfractaires | 400-400 - 400-1,200 | Défense, nucléaire, aérospatiale |

Titane et alliages à base de nickel sont préférés pour applications de haute performance, tandis que poudres d'acier inoxydable et d'aluminium offrir des solutions rentables pour l'industrie.

Demander un devis personnalisé pour les commandes en gros.

Méthodes de production des poudres d'impression 3D de métaux

Différents techniques de production de poudres l'impact sur la la forme, la pureté et le coût des particules de poudres métalliques pour l'impression 3D.

Comparaison des méthodes de production de poudres

| Méthode de production | Forme des particules | La pureté | Coût | Meilleur cas d'utilisation |

|---|---|---|---|---|

| Atomisation gazeuse (GA) | Sphérique | Haut | $$$ | LPBF, EBM, Jet de liant |

| Atomisation par plasma (PA) | Hautement sphérique | Très élevé | $$$$ | Applications médicales et aérospatiales |

| Atomisation de l'eau (WA) | Irrégulier | Modéré | $$ | Jet de liant, MIM |

| Procédé d'électrodes rotatives à plasma (PREP) | Extrêmement sphérique | Ultra-haut | $$$$$ | Applications aérospatiales et médicales à haute performance |

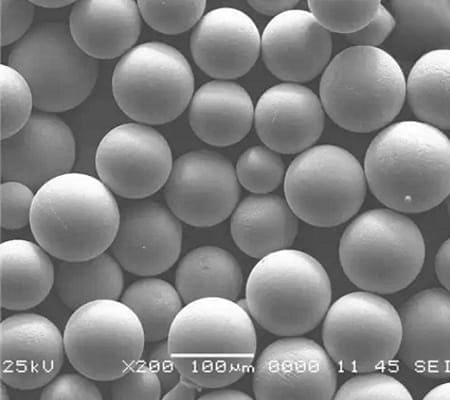

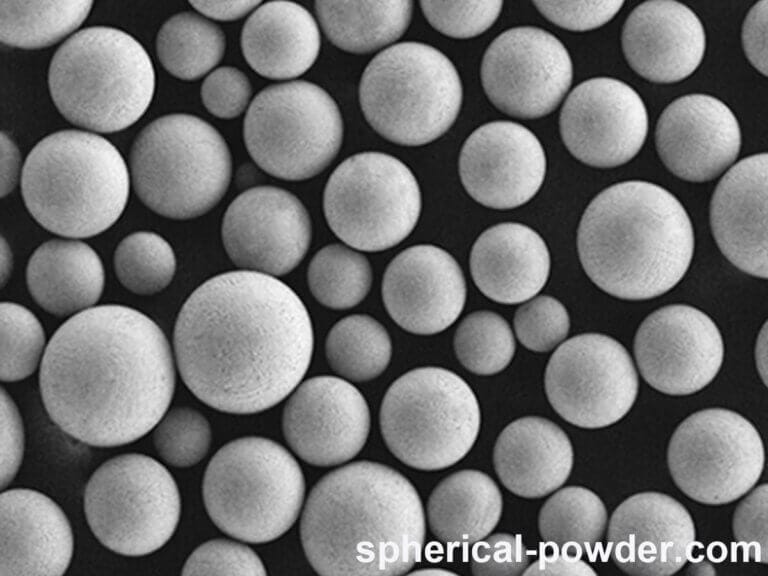

Atomisation par gaz et atomisation par plasma sont les méthodes les plus largement utilisées pour poudres d'impression 3D métalliques de haute qualité, en veillant à ce que excellente pureté, sphéricité et imprimabilité.

Heeger Materials Inc. se spécialise dans poudres métalliques atomisées par gaz et par plasma, délivrant une qualité et une cohérence supérieures.

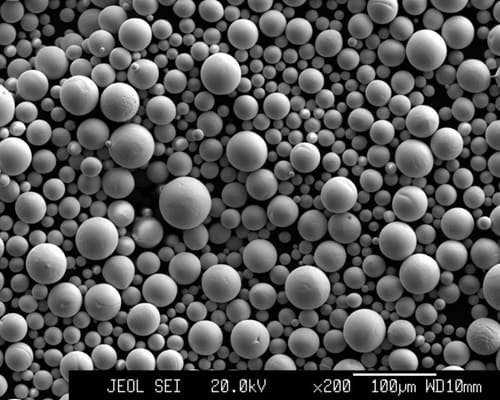

Taille et forme des particules dans les poudres d'impression 3D de métaux

Le la distribution de la taille des particules (DSP) et la morphologie jouent un rôle clé dans la fluidité des poudres, la densité de tassement et la qualité des pièces finales en procédés d'impression 3D de métaux.

Taille optimale des particules pour les applications d'impression 3D de métaux

| Gamme de taille des particules | Meilleure application |

|---|---|

| 15-45 µm | Fusion laser sur lit de poudre (LPBF, SLM, DMLS) |

| 45-75 µm | Fusion par faisceau d'électrons (EBM), dépôt par énergie dirigée (DED) |

| 75-150 µm | Jetting de liant, moulage par injection de métal (MIM) |

Poudre sphérique ou poudre irrégulière : quelle est la meilleure ?

| Forme de la poudre | Caractéristiques | Meilleure application |

|---|---|---|

| Sphérique | Excellente fluidité, emballage uniforme, haute imprimabilité | LPBF, EBM, Jet de liant |

| Irrégulier | Moins bonne fluidité, finition de surface plus rugueuse, coût plus faible | Jet de liant, MIM |

Poudres sphériques sont préférés pour fabrication additive métallique, en veillant à ce que une meilleure fluidité, une stratification uniforme et des défauts minimes.

Découvrez nos poudres métalliques sphériques de haute qualité.

Principaux fournisseurs en 2025

Trouver un fournisseur fiable est cruciale pour une qualité, une répétabilité et des performances constantes en impression 3D de métaux.

Principaux fournisseurs

| Nom du fournisseur | Pays | Spécialisation | Méthodes de production | Site web |

|---|---|---|---|---|

| Heeger Materials Inc. | ÉTATS-UNIS | Poudres pour l'impression 3D de métaux | VIGA, PREP, Atomisation à gaz | Visiter le site |

| Höganäs | Suède | Poudres métalliques pour l'AM | Atomisation de l'eau | N/A |

| Oerlikon Metco | Suisse | Poudres d'impression 3D pour l'aérospatiale et l'industrie | Atomisation des gaz | N/A |

| Sandvik | Suède | Poudres de rechargement et résistantes à l'usure | Atomisation des gaz | N/A |

À la recherche de poudres d'impression 3D métalliques à haute performance? Contactez Heeger Materials dès aujourd'hui !.

FAQ

| Question | Réponse |

|---|---|

| À quoi sert l'impression 3D de métaux ? | Il est utilisé pour applications aérospatiales, médicales, automobiles et industrielles exigeant pièces métalliques à haute performance. |

| Quel est le meilleur métal pour l'impression 3D de pièces aérospatiales ? | Alliages de titane (Ti6Al4V) et superalliages à base de nickel (Inconel 625, 718) sont préférés pour applications à haute température et légères. |

| Quelle est la meilleure méthode d'impression 3D pour les pièces métalliques ? | Fusion laser sur lit de poudre (LPBF) et fusion par faisceau d'électrons (EBM) offrir haute précision et excellentes propriétés mécaniques. |

| Quelle est la taille typique des particules des poudres d'impression 3D de métaux ? | 15-45 µm pour LPBF, 45-75 µm pour EBM, et 75-150 µm pour Binder Jetting. |

| Où puis-je acheter de la poudre d'impression 3D métallique de haute qualité ? | Heeger Materials Inc. fournit une prime poudres métalliques pour la fabrication additive. |

Conclusion

Impression 3D de métaux révolutionne l'industrie manufacturière dans tous les secteurs, permettant légèreté, haute résistance et géométries complexes que les méthodes traditionnelles ne peuvent atteindre.

Pour des poudres d'impression 3D métalliques de qualité supérieure, Heeger Materials Inc. fournit des solutions sur mesure avec poudres sphériques de haute pureté atomisées au gaz.

Vous recherchez une poudre d'impression 3D métallique de qualité supérieure ? Contactez-nous dès aujourd'hui !