Metall-3D-Druck 2025: Die Zukunft der additiven Fertigung

Überblick über den 3D-Druck von Metall

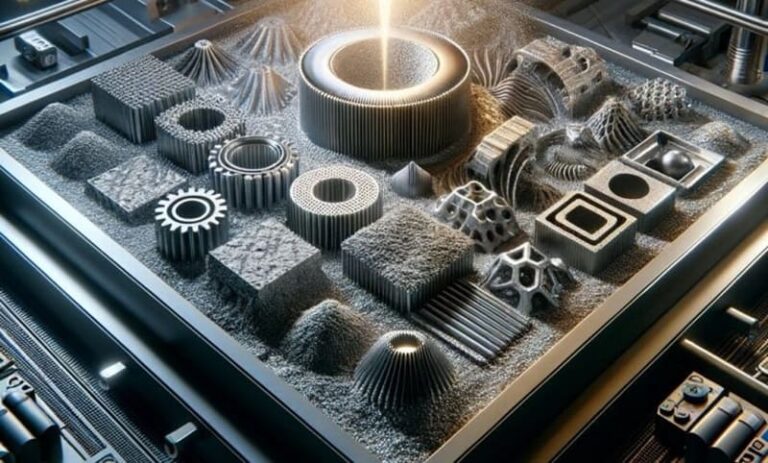

3D-Druck von Metall, auch bekannt als Additive Fertigung von Metall (AM)revolutioniert die Industrie, indem es die Produktion von komplexe, leistungsstarke Metallteile mit weniger Materialabfall, höhere Effizienz und mehr Gestaltungsfreiheit. Diese Technologie ist weit verbreitet in Luft- und Raumfahrt, Medizin, Automobil und industrielle Anwendungen wo herkömmliche Fertigungsmethoden versagen.

Durch die Nutzung von fortschrittliche MetallpulverDer 3D-Druck von Metall ermöglicht die Herstellung von leichte, hochfeste und hitzebeständige Komponentenund ist damit ein wichtiger Faktor für die Fertigung der nächsten Generation.

Unter Heeger Materials Inc.Wir sind spezialisiert auf hochwertige Metallpulver optimiert für verschiedene 3D-Druck Prozessedie eine hervorragende Bedruckbarkeit und mechanische Leistung gewährleisten.

Warum sollten Sie sich für den 3D-Druck von Metall entscheiden?

Der 3D-Druck von Metall bietet unübertroffene Vorteile als bei der traditionellen Herstellung, was sie ideal macht für Prototyping, Produktion und Anpassung.

Die wichtigsten Vorteile des 3D-Drucks von Metall

- Komplexe Geometrien und Leichtbaustrukturen - Ermöglicht Konstruktionen, die mit konventioneller Bearbeitung unmöglich sind.

- Reduzierter Materialabfall - Anders als subtraktive Fertigung3D-Druck von Metall minimiert den Abfall indem nur das erforderliche Material verwendet wird.

- Hervorragende mechanische Eigenschaften - Teile ausstellen hohe Festigkeit, Haltbarkeit und Hitzebeständigkeit.

- Individuelle Anpassung & schnelle Produktion - Ideal für Kleinserien, hochwertige Produktionsläufe.

- Effiziente Lieferketten - Reduziert Durchlaufzeiten und Logistikkosten.

Suche nach Hochleistungsmetallpulver für den 3D-Druck? Entdecken Sie die Auswahl von Heeger Materials.

Verwandte Produkte

-

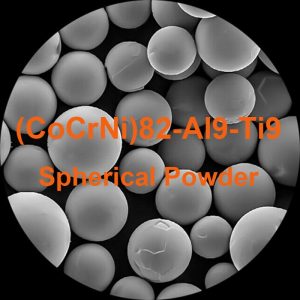

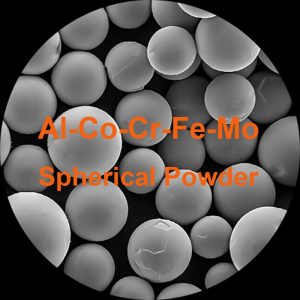

(CoCrNi)82-Al9-Ti9 Hochentropie-Legierung Kugelförmiges Pulver - (CoCrNi)82-Al9-Ti9 HEA - Additive Fertigung - 3D-Druck

-

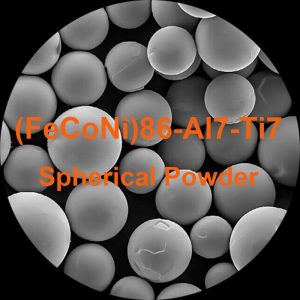

(FeCoNi)86-Al7-Ti7 Hochentropie-Legierung Kugelförmiges Pulver - (FeCoNi)86-Al7-Ti7 HEA - Additive Fertigung - 3D-Druck

-

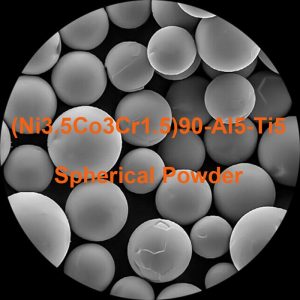

(Ni3.5Co3Cr1.5)90-Al5-Ti5 Hochentrope Legierung Kugelförmiges Pulver - (Ni3.5Co3Cr1.5)90-Al5-Ti5 HEA - Additive Fertigung - 3D-Druck

-

Al-Co-Cr-Fe-Mo Hochentropie-Legierung Kugelförmiges Pulver - Al-Co-Cr-Fe-Mo HEA - Additive Fertigung - 3D-Druck

Beste Metallpulver für den 3D-Druck

Die Auswahl der richtiges Metallpulver ist entscheidend für Druckbarkeit, mechanische Eigenschaften und Leistung des fertigen Teils.

Vergleich von Metallpulvern für den 3D-Druck

| Metall-Pulver | Wichtige Eigenschaften | Beste Anwendungen |

|---|---|---|

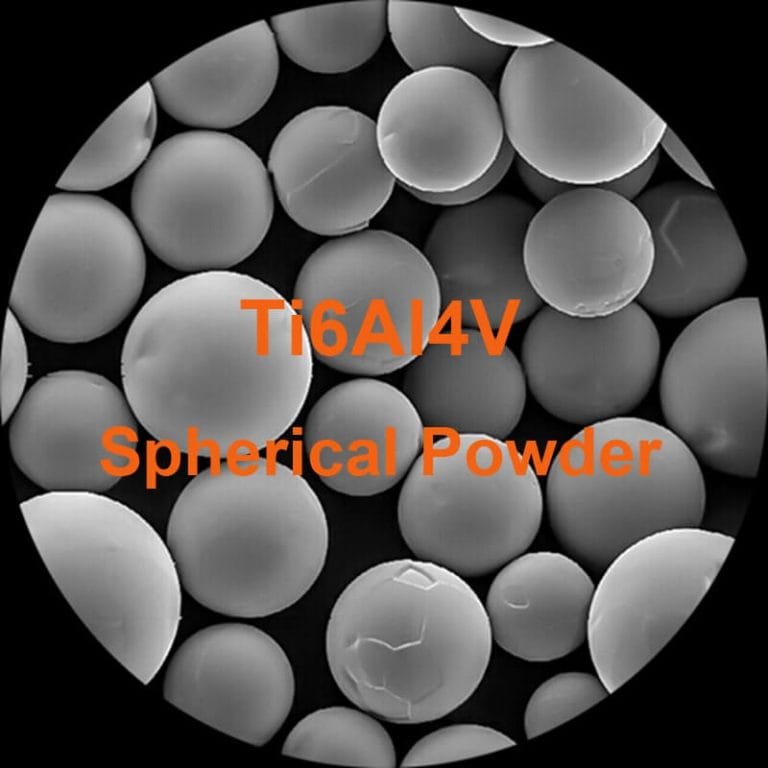

| Titan-Legierungen (Ti6Al4V) | Leicht, hochfest, biokompatibel | Luft- und Raumfahrt, medizinische Implantate |

| Nickel-Basis-Legierungen (Inconel 625, 718) | Hochtemperaturbeständigkeit, Korrosionsbeständigkeit | Luft- und Raumfahrt, Energie, Automobil |

| Kobalt-Basis-Legierungen (Stellit, CoCrMo) | Abrieb- und Oxidationsbeständigkeit | Medizinische, zahnmedizinische und industrielle Werkzeuge |

| Rostfreier Stahl (316L, 17-4PH) | Hohe Festigkeit, Korrosionsbeständigkeit | Industrie, Marine, Medizin |

| Aluminium-Legierungen (AlSi10Mg, Al7075) | Leichtes Gewicht, gute Wärmeleitfähigkeit | Automobilindustrie, Luft- und Raumfahrt |

| Kupfer und Kupferlegierungen | Hohe thermische und elektrische Leitfähigkeit | Elektronik, Wärmetauscher |

| Wolfram und hochschmelzende Metalle | Hohe Dichte, extreme Hitzebeständigkeit | Verteidigung, Kerntechnik, Luft- und Raumfahrt |

Nickel-Basis-Legierungen und Titan-Pulver werden bevorzugt für hochleistungsanwendungen, während Pulver aus rostfreiem Stahl und Aluminium Angebot kostengünstige Lösungen.

Fordern Sie ein individuelles Angebot für 3D-Druckpulver aus Metall an.

3D-Drucktechnologien für Metall

Anders 3D-Drucktechnologien werden verwendet für Metall-Additiv-Fertigungmit jeweils einzigartigen Vorteile und Materialverträglichkeit.

Vergleich der 3D-Druckverfahren für Metall

| 3D-Druckverfahren | Prozess-Typ | Beste Materialien | Wichtigste Vorteile |

|---|---|---|---|

| Laser-Pulver-Bett-Fusion (LPBF/SLM/DMLS) | Pulverförmig | Titan, Nickel, rostfreier Stahl | Hohe Präzision, feine Details |

| Elektronenstrahlschmelzen (EBM) | Pulverförmig | Titan, Kobalt-Chrom | Hochtemperaturverarbeitung, Massenproduktion |

| Binder Jetting | Pulverförmig | Rostfreier Stahl, Bronze | Kosteneffiziente, groß angelegte Produktion |

| Gerichtete Energieabscheidung (DED/LMD) | Draht- oder pulverbasiert | Nickel, Titan, rostfreier Stahl | Reparatur & Hybridfertigung |

| Metallbinder-Strahlen | Pulverförmig | Rostfreier Stahl, Kupfer | Kostengünstige Produktion in hohen Stückzahlen |

LPBF (SLM/DMLS) und EBM sind die am häufigsten verwendeten für Hochleistungsanwendungen in der Luft- und Raumfahrt sowie in der Medizin, während Binder Jetting und DED sind ideal für kostengünstige Massenproduktion.

Finden Sie das beste Metallpulver für Ihren 3D-Druckprozess.

Anwendungen des 3D-Drucks von Metall in der Industrie

Der 3D-Metalldruck verändert die Industrie und ermöglicht leichte, leistungsstarke und kostengünstige Komponenten.

Wichtige industrielle Anwendungen

| Industrie | Anmeldung | Vorteile |

|---|---|---|

| Luft- und Raumfahrt & Verteidigung | Leichte Strukturkomponenten, Turbinenschaufeln | Hohe Leistung, geringes Gewicht |

| Automobilindustrie | Kundenspezifische Motorenteile, Leichtbaukomponenten | Verbesserte Kraftstoffeffizienz, schnelles Prototyping |

| Medizinisch & Zahnmedizinisch | Patientenspezifische Implantate, Prothetik | Biokompatibilität, Präzisionsfertigung |

| Energie und Stromerzeugung | Wärmetauscher, Gasturbinen | Hochtemperaturbeständigkeit, Langlebigkeit |

| Industrielle Werkzeuge | Formen, Gesenke, verschleißfeste Beschichtungen | Verlängerte Standzeit, Kosteneinsparungen |

Mit dem Aufkommen von Elektrofahrzeuge (EVs) und fortschrittliche Luft- und Raumfahrtkomponenten, Der 3D-Metalldruck treibt Innovationen in der Fertigung der nächsten Generation voran.

Entdecken Sie unsere leistungsstarken 3D-Druckpulver aus Metall.

Qualitätsstandards für 3D-Druck-Pulver aus Metall

Um sicherzustellen zuverlässiges und wiederholbares DruckenMetallpulver müssen folgende Anforderungen erfüllen strenge Qualitätsstandards.

Wichtige Qualitätsstandards für Metall-3D-Druck-Pulver

| Standard | Beschreibung |

|---|---|

| ASTM F3049 | Standard für Charakterisierung von Metallpulvern in der additiven Fertigung. |

| ASTM F3302 | Spezifikation für Metallpulver, die bei AM-Prozessen im Pulverbettschmelzverfahren (PBF) verwendet werden. |

| ISO 52907 | Leitlinien für Qualitätskontrolle von Pulvern für die additive Fertigung. |

| AMS 4999 | Luft- und Raumfahrt-Materialspezifikation für Nickel- und Titan-Pulver. |

| RoHS-Konformität | Gewährleistet umweltsicherheit durch Begrenzung gefährlicher Stoffe. |

Unter Heeger Materials Inc.wir fertigen hochreine Metallpulver die mit ASTM-, ISO- und AMS-Normenund gewährleistet hervorragende Bedruckbarkeit und mechanische Leistung.

Kostenanalyse von Metall-3D-Druckpulvern

Die Kosten für 3D-Druck-Pulver aus Metall variiert je nach Materialzusammensetzung, Herstellungsverfahren und Nachfrage der Industrie. Hochleistungslegierungen wie Titan, Superlegierungen auf Nickelbasis und Pulver auf Kobaltbasis neigen dazu teurer aufgrund ihrer erweiterte mechanische Eigenschaften und Verarbeitungsanforderungen.

Faktoren, die die Kosten für Metall-3D-Druckpulver beeinflussen

- Materialzusammensetzung - Exotische Legierungen (Titan, Inconel, Kobalt-Chrom) sind teurer als rostfreier Stahl oder Aluminiumpulver.

- Produktionsverfahren - Gaszerstäubung und Plasmazerstäubung erzeugen hochkugelförmige, hochreine Pulver und erhöhen die Kosten.

- Partikelgrößenverteilung (PSD) - Feinere Pulver (15-45µm) für LPBF sind aufgrund der Präzisionsanforderungen teurer.

- Reinheit und Sauerstoffgehalt - Niedrigere Sauerstoffgehalte verbessern die mechanischen Eigenschaften, erhöhen aber die Produktionskosten.

- Marktnachfrage und Angebot - Die Preise schwanken je nach Verfügbarkeit von Rohstoffen, Branchentrends und geopolitische Faktoren.

Preisvergleich von Metall-3D-Druckpulvern

| Metallpulver Typ | Kosten ($/kg) | Gemeinsame Anwendungen |

|---|---|---|

| Titan-Legierung (Ti6Al4V) | 300-300 - 300-700 | Luft- und Raumfahrt, medizinische Implantate |

| Superlegierung auf Nickelbasis (Inconel 625, 718) | 350-350 - 350-900 | Hochtemperaturkomponenten für die Luft- und Raumfahrt |

| Kobalt-Chrom-Legierung (CoCrMo) | 250-250 – 250-600 | Medizinische Implantate, zahnmedizinische Anwendungen |

| Rostfreier Stahl (316L, 17-4PH) | 80-80 - 80-250 | Industrie, Marine, Medizin |

| Aluminiumlegierung (AlSi10Mg, Al7075) | 80-80 - 80-250 | Automobilindustrie, Luft- und Raumfahrt |

| Kupfer und Kupferlegierungen | 100-100 - 100-500 | Elektronik, Wärmetauscher |

| Wolfram- und Refraktärmetall-Pulver | 400-400 - 400-1,200 | Verteidigung, Kerntechnik, Luft- und Raumfahrt |

Titan- und Nickelbasislegierungen werden bevorzugt für hochleistungsanwendungen, während Pulver aus rostfreiem Stahl und Aluminium Angebot kostengünstige Lösungen für den industriellen Einsatz.

Fordern Sie ein individuelles Angebot für Großaufträge an.

Produktionsmethoden für Metall-3D-Druckpulver

Anders Techniken der Pulverherstellung auswirkungen auf die partikelform, Reinheit und Kosten von 3D-Druck-Pulver aus Metall.

Vergleich von Pulverherstellungsmethoden

| Produktionsverfahren | Partikelform | Reinheit | Kosten | Bester Anwendungsfall |

|---|---|---|---|---|

| Gaszerstäubung (GA) | Sphärisch | Hoch | $$$ | LPBF, EBM, Binder Jetting |

| Plasma-Zerstäubung (PA) | Hochgradig sphärisch | Sehr hoch | $$$$ | Medizinische Anwendungen, Luft- und Raumfahrt |

| Wasserzerstäubung (WA) | Unregelmäßig | Mäßig | $$ | Binder Jetting, MIM |

| Plasma-Rotations-Elektroden-Verfahren (PREP) | Äußerst kugelförmig | Ultra-Hoch | $$$$$ | Hochleistungsanwendungen für Luft- und Raumfahrt und Medizin |

Gaszerstäubung und Plasmazerstäubung sind die am weitesten verbreiteten Methoden zur Hochwertige Metall-3D-Druck-Pulverund gewährleistet ausgezeichnete Reinheit, Sphärizität und Druckfähigkeit.

Heeger Materials Inc. ist spezialisiert auf gas- und plasmagestäubte Metallpulverund liefert hervorragende Qualität und Konsistenz.

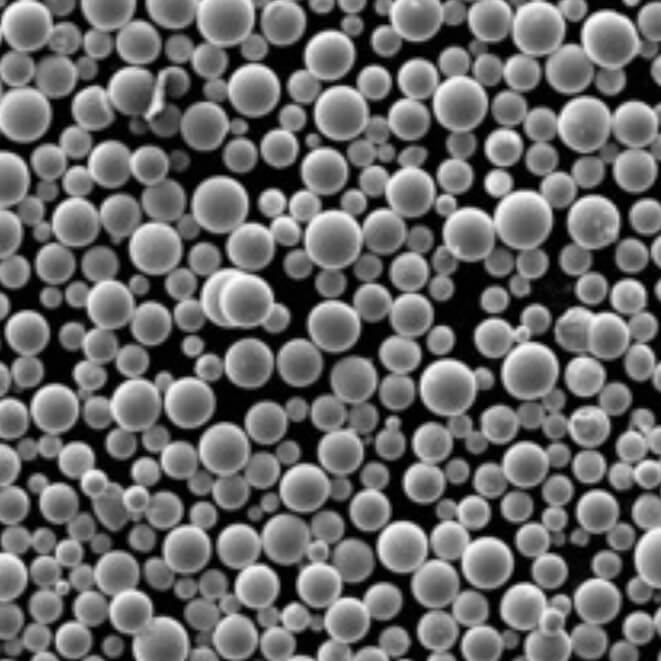

Partikelgröße und -form in Metall-3D-Druckpulvern

Die Partikelgrößenverteilung (PSD) und Morphologie eine Schlüsselrolle spielen bei Fließfähigkeit des Pulvers, Packungsdichte und Qualität des Endprodukts in 3D-Druckverfahren für Metall.

Optimale Partikelgröße für 3D-Druckanwendungen aus Metall

| Partikelgrößenbereich | Beste Anwendung |

|---|---|

| 15-45 µm | Laser-Pulver-Bett-Fusion (LPBF, SLM, DMLS) |

| 45-75 µm | Elektronenstrahlschmelzen (EBM), gerichtete Energieabscheidung (DED) |

| 75-150 µm | Binder Jetting, Metall-Spritzgießen (MIM) |

Sphärisches vs. unregelmäßiges Pulver: Was ist besser?

| Pulverform | Merkmale | Beste Anwendung |

|---|---|---|

| Sphärisch | Ausgezeichnete Fließfähigkeit, gleichmäßige Verpackung, hohe Bedruckbarkeit | LPBF, EBM, Binder Jetting |

| Unregelmäßig | Geringere Fließfähigkeit, rauere Oberfläche, niedrigere Kosten | Binder Jetting, MIM |

Sphärische Pulver werden bevorzugt für Metall-Additiv-Fertigungund gewährleistet bessere Fließfähigkeit, gleichmäßige Schichtung und minimale Fehler.

Entdecken Sie unsere hochwertigen sphärischen Metallpulver.

Top-Lieferanten im Jahr 2025

Die Suche nach einem zuverlässiger Lieferant ist entscheidend für gleichbleibende Qualität, Wiederholbarkeit und Leistung in 3D-Druck von Metall.

Führende Anbieter

| Name des Lieferanten | Land | Spezialisierung | Produktionsmethoden | Website |

|---|---|---|---|---|

| Heeger Materials Inc. | USA | Metall-3D-Druck-Pulver | VIGA, PREP, Gaszerstäubung | Website besuchen |

| Höganäs | Schweden | Metallpulver für AM | Wasserzerstäubung | K.A |

| Oerlikon Metco | Schweiz | 3D-Druckpulver für Luft- und Raumfahrt und Industrie | Gaszerstäubung | K.A |

| Sandvik | Schweden | Hartauftragsschweißen & verschleißfeste Pulver | Gaszerstäubung | K.A |

Suche nach Hochleistungsmetallpulver für den 3D-Druck? Kontaktieren Sie Heeger Materials noch heute!.

FAQ

| Frage | Antwort |

|---|---|

| Wozu dient der 3D-Druck von Metall? | Es wird verwendet für Luft- und Raumfahrt, Medizin, Automobil und industrielle Anwendungen mit Hochleistungsmetallteile. |

| Welches ist das beste Metall für den 3D-Druck von Teilen für die Luft- und Raumfahrt? | Titanlegierungen (Ti6Al4V) und Nickelbasis-Superlegierungen (Inconel 625, 718) werden bevorzugt für Hochtemperatur- und Leichtbauanwendungen. |

| Welches 3D-Druckverfahren eignet sich am besten für Metallteile? | Laser-Pulver-Bett-Fusion (LPBF) und Elektronenstrahlschmelzen (EBM) Angebot hohe Präzision und hervorragende mechanische Eigenschaften. |

| Was ist die typische Partikelgröße für 3D-Druck-Pulver aus Metall? | 15-45 µm für LPBF, 45-75 µm für EBM und 75-150 µm für Binder Jetting. |

| Wo kann ich hochwertiges 3D-Druckpulver aus Metall kaufen? | Heeger Materials Inc. bietet Premium Metallpulver für die additive Fertigung. |

Schlussfolgerung

3D-Druck von Metall revolutioniert Branchenübergreifende Fertigungermöglicht leichte, hochfeste und komplexe Geometrien die mit traditionellen Methoden nicht erreicht werden können.

Für Hochwertige 3D-Druckpulver aus Metall, Heeger Materials Inc. bietet maßgeschneiderte Lösungen mit hochreine, gaszerstäubte kugelförmige Pulver.

Sie suchen hochwertiges 3D-Druckpulver aus Metall? Kontaktieren Sie uns noch heute!