Poudre d'alliage magnétique doux 2025 : Matériaux avancés pour les applications magnétiques à haut rendement

Vue d'ensemble

Poudre d'alliage magnétique doux est un matériau spécialisé conçu pour applications électromagnétiques de haute performance, y compris moteurs électriques, transformateurs, inducteurs et systèmes de recharge sans fil. Ces poudres présentent haute perméabilité, faible coercivité et faible perte de noyauils sont donc idéaux pour applications à haute fréquence et conceptions à haut rendement énergétique.

Avec la demande croissante de des composants électriques légers et économes en énergie, poudres d'alliages magnétiques doux révolutionnent des secteurs tels que automobile (moteurs de véhicules électriques), aérospatiale, télécommunications et électronique de puissance.

Au Heeger Materials Inc.Nous sommes spécialisés dans poudres d'alliages magnétiques doux de haute pureté et sur mesure optimisé pour applications électromagnétiques avancées.

Pourquoi choisir la poudre d'alliage magnétique doux ?

Les poudres magnétiques douces sont essentiel pour optimiser les performances électromagnétiques dans les applications modernes où les efficacité énergétique, miniaturisation et haute densité de puissance sont essentiels.

Principaux avantages

- Perméabilité magnétique élevée - Améliore la conduction du flux dans les composants électromagnétiques.

- Faible coercivité - Réduit perte d'énergie et hystérésis.

- Faible perte de noyau - Améliore efficacité dans les applications à haute fréquence.

- Excellente stabilité thermique - Garantit des performances constantes dans des conditions d'utilisation variables.

- Taille et composition des particules personnalisables - Sur mesure pour des applications spécifiques telles que les moteurs à grande vitesse et les inductances de puissance.

À la recherche de poudres d'alliages magnétiques doux optimisées ? Découvrez la sélection de Heeger Materials.

Produits apparentés

-

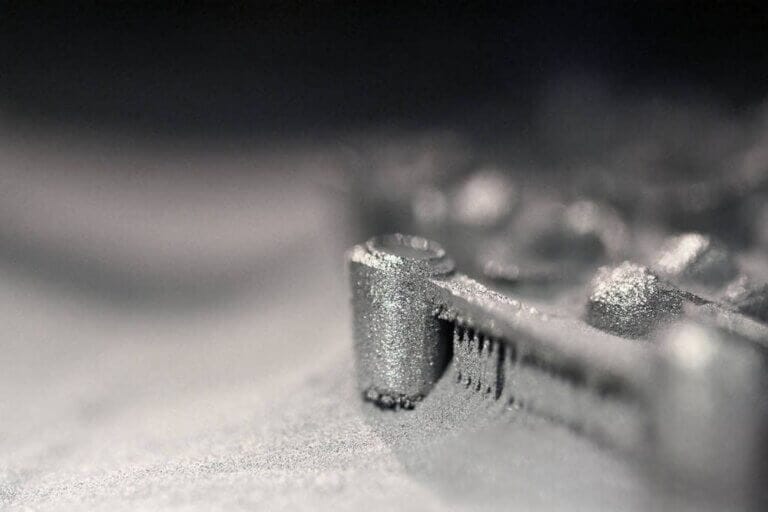

Poudre sphérique d'alliage magnétique doux Fe54Cr25Mo16B2C2.6 - Poudre Fe54Cr25Mo16B2C2.6 - Fabrication additive - Impression 3D

-

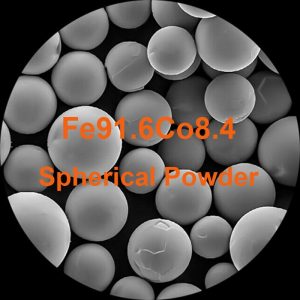

Poudre sphérique d'alliage magnétique doux Fe91.6Co8.4 - Poudre Fe91.6Co8.4 - Fabrication additive - Impression 3D

-

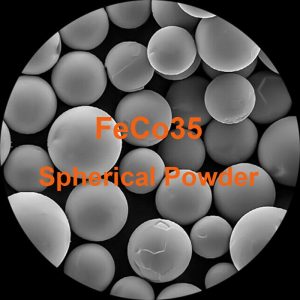

Poudre d'alliage magnétique doux FeCo35 - Poudre FeCo35 - Fabrication additive - Impression 3D

-

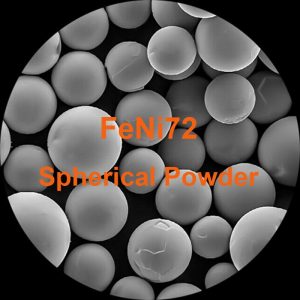

Poudre sphérique d'alliage magnétique doux FeNi72 - Poudre FeNi72 - Fabrication additive - Impression 3D

Types courants

Différents alliages magnétiques doux sont optimisés pour applications spécifiques sur la base de leur composition, perméabilité et caractéristiques de perte de noyau.

Comparaison

| Type d'alliage | Propriétés principales | Applications courantes |

|---|---|---|

| Alliage fer-silicium (Fe-Si) | Résistivité électrique élevée, faible perte de noyau | Transformateurs, moteurs électriques |

| Alliage fer-nickel (Fe-Ni) (Permalloy) | Perméabilité élevée, faible coercivité | Blindage magnétique, capteurs, inducteurs |

| Alliage fer-cobalt (Fe-Co) | Magnétisation à saturation élevée, densité de puissance supérieure | Aérospatiale, moteurs à grande vitesse |

| Poudres de ferrite molle (ferrites MnZn, NiZn) | Résistivité élevée, utilisée dans les applications à haute fréquence | Inducteurs, transformateurs, charge sans fil |

| Poudres magnétiques amorphes et nanocristallines | Perte de noyau ultra-faible, efficacité à haute fréquence | Électronique de puissance à haut rendement, composants pour véhicules électriques (VE) |

Alliages fer-silicium et fer-nickel dominer l'électronique de puissance et les transformateurs, tandis que Alliages fer-cobalt sont préférés pour applications aérospatiales et de défense à haute performance.

Demande de devis personnalisé pour les poudres d'alliages magnétiques doux.

Applications de la poudre d'alliage magnétique doux dans l'industrie

Les poudres magnétiques douces façonnent l'avenir de l'industrie automobile applications électromagnétiques et à haut rendement énergétique.

Applications industrielles clés

| L'industrie | Application | Avantages |

|---|---|---|

| Automobile (EV Motors) | Moteurs électriques à haut rendement | Perte d'énergie réduite, densité de couple plus élevée |

| Électronique de puissance | Inducteurs, transformateurs | Amélioration de l'efficacité énergétique, réduction de la production de chaleur |

| Aérospatiale et défense | Actionneurs à grande vitesse, blindage magnétique | Matériaux légers et performants |

| Énergies renouvelables | Générateurs d'éoliennes | Efficacité accrue de la conversion énergétique |

| Télécommunications | Systèmes de recharge sans fil, filtres | Stabilité à haute fréquence, miniaturisation |

Avec l'essor des véhicules électriques (VE) et les énergies renouvelables, poudres d'alliages magnétiques doux jouent un rôle crucial dans la conversion de l'énergie et le rendement des moteurs.

Découvrez nos poudres magnétiques douces haute performance.

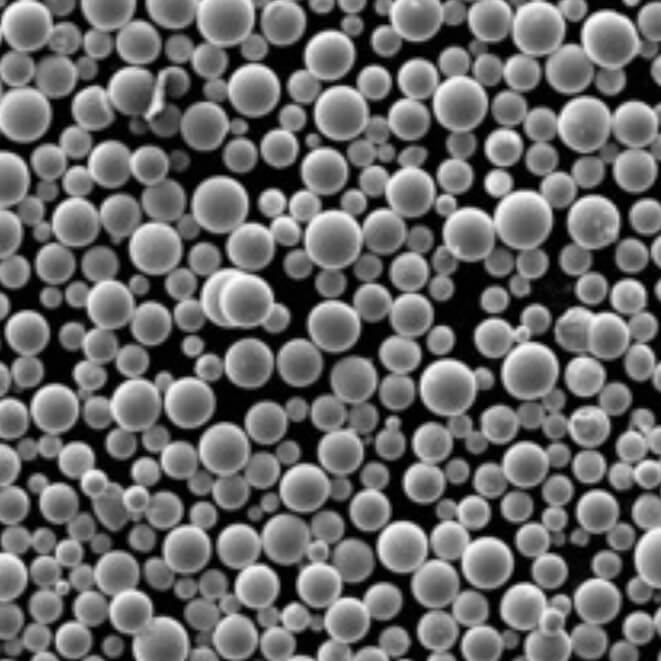

Taille et forme des particules dans les poudres d'alliages magnétiques doux

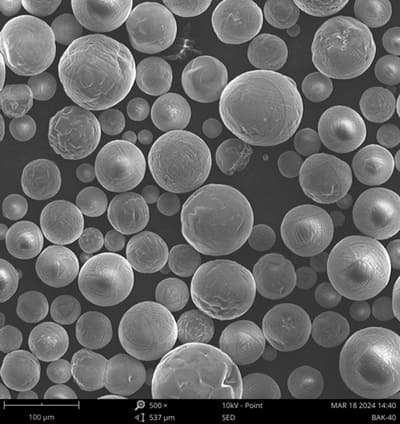

Le la distribution de la taille des particules (DSP) et la morphologie avoir un impact significatif performance magnétique, perméabilité et perte de noyau.

Taille optimale des particules pour les applications magnétiques douces

| Gamme de taille des particules | Meilleure application |

|---|---|

| 1-10 µm | Inducteurs haute fréquence, transformateurs |

| 10-45 µm | Blindage électromagnétique, capteurs |

| 45-150 µm | Moteurs électriques, électronique de puissance |

Poudre sphérique ou poudre irrégulière : quelle est la meilleure ?

| Forme de la poudre | Caractéristiques | Meilleure application |

|---|---|---|

| Sphérique | Meilleure densité d'empilement, perméabilité améliorée, perte de courant de Foucault réduite | Applications haute fréquence, électronique de puissance |

| Irrégulier | Surface plus importante, coût plus faible | Blindage magnétique, applications générales |

Poudres magnétiques douces sphériques sont préférés pour applications à haute fréquence et à haut rendement, en veillant à ce que propriétés magnétiques supérieures.

Découvrez nos poudres d'alliage magnétique doux optimisées.

Principaux fournisseurs de poudres d'alliages magnétiques doux en 2025

Trouver un fournisseur fiable est cruciale pour qualité et performance constantes de la poudre d'alliage magnétique doux.

Principaux fournisseurs de poudre d'alliage magnétique doux

| Nom du fournisseur | Pays | Spécialisation | Méthodes de production | Site web |

|---|---|---|---|---|

| Heeger Materials Inc. | ÉTATS-UNIS | Poudres d'alliages magnétiques doux | VIGA, PREP, Atomisation à gaz | Visiter le site |

| Höganäs | Suède | Poudres magnétiques douces | Atomisation de l'eau | N/A |

| Métaux Hitachi | Japon | Matériaux magnétiques haute performance | Atomisation des gaz | N/A |

| Groupe VAC | Allemagne | Poudres amorphes et nanocristallines | Atomisation des gaz | N/A |

Heeger Materials Inc. se spécialise dans poudres d'alliage magnétique doux personnalisées, délivrant matériaux de haute qualité et de haute performance pour les applications électromagnétiques.

Contactez Heeger Materials pour des poudres magnétiques douces de qualité supérieure..

Normes de qualité pour les poudres d'alliages magnétiques doux

Garantir poudres d'alliages magnétiques doux de haute qualité est cruciale pour conversion efficace de l'énergie, réduction des pertes dans le noyau et amélioration des performances électromagnétiques. Divers normes internationales réguler la composition, la taille des particules et les propriétés magnétiques de ces poudres afin de répondre aux exigences de l'Union européenne. les exigences de l'aérospatiale, de l'automobile et de l'industrie.

Principales normes de qualité pour les poudres d'alliages magnétiques doux

| Standard | Description |

|---|---|

| ASTM A804 | Norme pour les alliages magnétiques doux à base de fer. |

| ASTM A839 | Spécification pour Alliages magnétiques doux fer-cobalt-vanadium. |

| IEC 60404-8-6 | Classification des Poudres magnétiques douces Fe-Si. |

| ISO 3934 | Lignes directrices pour métallurgie des poudres matériaux magnétiques doux. |

| JIS C 2524 | La norme japonaise pour les matériaux pour noyaux magnétiques doux. |

| Conformité RoHS | Veille la sécurité environnementale en limitant les substances dangereuses. |

Pourquoi choisir les poudres d'alliage magnétique doux certifiées ?

- Garantit des propriétés magnétiques constantes - Maintient perméabilité uniforme et faible coercivité.

- Optimisé pour les applications à haute fréquence - Minimise pertes par courants de Foucault dans les transformateurs et les inductances.

- Poudres de haute pureté - Réduit les impuretés qui dégradent la performance magnétique.

- Conformité aux normes automobiles et aérospatiales - Garantit la sécurité et l'efficacité dans les applications des moteurs électriques.

Au Heeger Materials Inc.nous fabriquons poudres magnétiques douces de haute pureté qui sont conformes aux Normes ASTM, ISO et IEC, en veillant à ce que une performance électromagnétique optimale.

Analyse des coûts des poudres d'alliages magnétiques doux

Le prix des poudres d'alliages magnétiques doux dépend de composition du matériau, méthode de production et exigences d'application.

Facteurs influençant le coût de la poudre d'alliage magnétique doux

- Composition du matériau - Alliages fer-cobalt et alliages nanocristallins sont plus chers que les Alliages Fe-Si et Fe-Ni.

- Méthode de production - Atomisation par gaz et atomisation par plasma produire des poudres sphériques de meilleure qualité, ce qui entraîne une augmentation des coûts.

- Distribution de la taille des particules (PSD) - Les poudres plus fines (1-10µm) pour les applications à haute fréquence sont plus chères. en raison de une plus grande précision de traitement.

- Pureté magnétique - Moins d'impuretés et teneur en oxygène contrôlée améliorer les performances, mais augmenter les coûts de production.

- Offre et demande mondiales - Les prix fluctuent en fonction la disponibilité des matières premières et les tendances de l'industrie.

Comparaison des prix des poudres d'alliages magnétiques doux

| Type d'alliage | Coût ($/kg) | Cas d'utilisation courante |

|---|---|---|

| Alliage Fe-Si (Fer-Silicium) | 50-50 – ; 50-150 | Transformateurs, moteurs électriques |

| Alliage Fe-Ni (Permalloy) | 100-100 – ; 100-300 | Blindage magnétique, capteurs |

| Alliage Fe-Co (fer-cobalt) | 300-300 - 300-700 | Aérospatiale, moteurs à grande vitesse |

| Poudres magnétiques nanocristallines | 500-500 - 500-1,200 | Électronique de puissance à haute fréquence |

| Poudres de ferrite molle | 30-30 - 30-100 | Inducteurs, charge sans fil |

Alliages nanocristallins et Fe-Co sont plus cher en raison de leur efficacité et densité de puissance supérieures à haute fréquence, tandis que Poudres de Fe-Si et de ferrite offrir des solutions rentables pour les applications industrielles.

Demander un devis personnalisé pour les commandes en gros.

Méthodes de production de poudres d'alliages magnétiques doux

Différents techniques de production de poudres l'impact sur la la forme, la pureté et le coût des particules de poudres d'alliages magnétiques doux.

Comparaison des méthodes de production de poudres

| Méthode de production | Forme des particules | La pureté | Coût | Meilleur cas d'utilisation |

|---|---|---|---|---|

| Atomisation gazeuse (GA) | Sphérique | Haut | $$$ | Moteurs électriques, transformateurs |

| Atomisation par plasma (PA) | Hautement sphérique | Très élevé | $$$$ | Inducteurs haute fréquence, applications aérospatiales |

| Atomisation de l'eau (WA) | Irrégulier | Modéré | $$ | Blindage magnétique, applications générales |

| Fraisage mécanique | Comme un flocon | Modéré | $$ | Noyaux magnétiques, capteurs |

Atomisation par gaz et atomisation par plasma sont privilégiées pour les applications électromagnétiques de haute performance, en veillant à ce que excellente pureté, sphéricité et performance magnétique.

Heeger Materials Inc. se spécialise dans poudres magnétiques douces atomisées par gaz et par plasma, délivrant des matériaux de haute qualité pour des applications avancées.

FAQ sur les poudres d'alliages magnétiques doux

| Question | Réponse |

|---|---|

| À quoi servent les poudres d'alliages magnétiques doux ? | Ils sont utilisés dans moteurs électriques, transformateurs, inducteurs et blindage magnétique pour applications électromagnétiques à haut rendement. |

| Quel est le meilleur matériau magnétique doux pour les applications à haute fréquence ? | Poudres magnétiques nanocristallines et amorphes offrir perte de noyau ultra-faible et excellente performance à haute fréquence. |

| Quelle est la différence entre les alliages magnétiques doux Fe-Si et Fe-Ni ? | Alliages Fe-Si fournir faible perte de noyau et résistivité électrique élevée, tandis que Les alliages Fe-Ni (Permalloy) offrent une perméabilité élevée et une faible coercivité.. |

| Quelle est la taille typique des particules des poudres magnétiques douces ? | 1-10 µm pour les applications à haute fréquence, 10-45 µm pour le blindage et 45-150 µm pour les moteurs électriques. |

| Où puis-je acheter de la poudre d'alliage magnétique doux de haute qualité ? | Heeger Materials Inc. fournit une prime poudres magnétiques douces pour les applications industrielles. |

Conclusion

Poudres d'alliages magnétiques doux sont à l'origine d'innovations dans les domaines suivants applications électromagnétiques, permettant une meilleure efficacité énergétique, des performances améliorées et la miniaturisation dans des secteurs tels que Moteurs de véhicules électriques, électronique de puissance et aérospatiale.

Pour poudres d'alliages magnétiques doux de qualité supérieure, Heeger Materials Inc. fournit des solutions sur mesure avec poudres sphériques de haute pureté atomisées au gaz.

Vous recherchez de la poudre d'alliage magnétique doux de première qualité ? Contactez-nous dès aujourd'hui !