Poudre de fabrication additive 2025 : Le guide ultime des matériaux, des applications et des fournisseurs

Vue d'ensemble de la poudre de fabrication additive

Poudre de fabrication additive (AM) se réfère à des produits finement broyés poudres métalliques, polymères ou céramiques utilisé dans Procédés d'impression 3D tels que Fusion laser sur lit de poudre (LPBF), fusion par faisceau d'électrons (EBM), projection de liant et dépôt par énergie directe (DED).. Ces poudres permettent haute résistance, légèreté et géométries complexes que la fabrication traditionnelle ne peut atteindre.

En 2025Les poudres AM sont le moteur de l'innovation dans les domaines suivants applications aérospatiales, médicales, automobiles et industrielles, ce qui permet de des composants personnalisés et performants.

Ce guide explore les les meilleures poudres de fabrication additive, leurs propriétés, les méthodes de production et les fournisseurs de confiance pour matériaux AM de haute qualité.

Meilleure poudre de fabrication additive pour l'impression 3D

Choisir le bon Poudre AM dépend de application, propriétés mécaniques et compatibilité avec les imprimantes.

Principales poudres métalliques pour la fabrication additive

| Matériau | Propriétés principales | Applications courantes |

|---|---|---|

| Titane Ti6Al4V | Léger, rapport résistance/poids élevé, biocompatible | Aérospatiale, implants médicaux |

| Acier inoxydable 316L | Résistant à la corrosion, robuste, facile à imprimer | Outils médicaux, composants industriels |

| Inconel 718 | Résistance aux hautes températures, résistance à l'oxydation | Aérospatiale, énergie, défense |

| Alliage d'aluminium AlSi10Mg | Léger, excellente conductivité thermique | Automobile, aérospatiale |

| Poudre de tungstène | Haute densité, protection contre les radiations | Aérospatiale, défense, applications nucléaires |

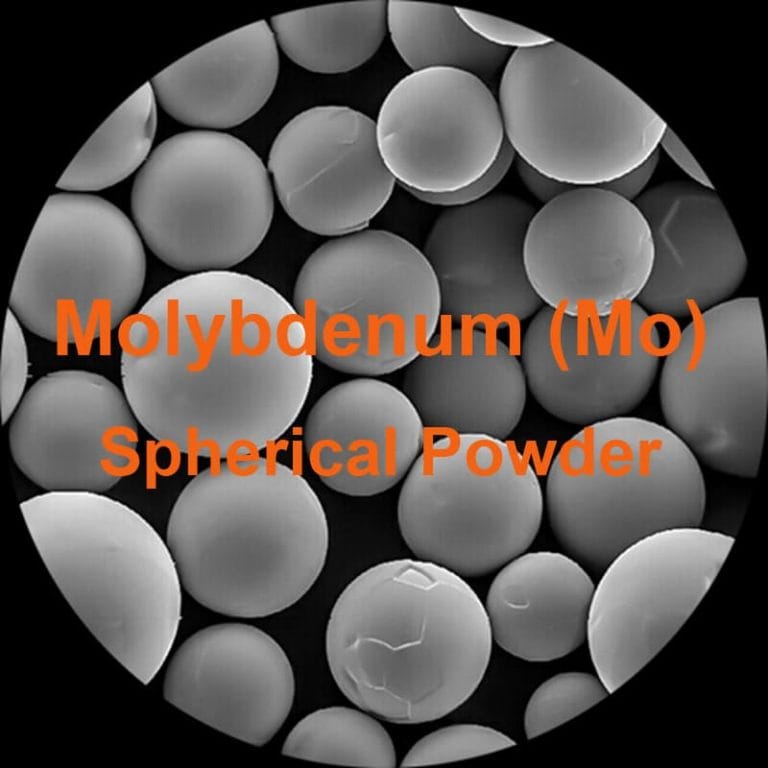

| Poudre de molybdène | Résistance à haute température, conductivité thermique | Électronique, aérospatiale |

Chaque poudre est optimisée pour Technologies d'impression LPBF, SLM, EBM et DED.

Comparaison des poudres pour la fabrication additive

| Type de poudre | La force | Densité | Point de fusion (°C) | Résistance à la corrosion | Coût ($/kg) |

|---|---|---|---|---|---|

| Titane Ti6Al4V | ★★★★☆ | Faible | 1660 | Haut | $$$$ |

| Acier inoxydable 316L | ★★★☆☆ | Moyen | 1400-1450 | Haut | $$$ |

| Aluminium AlSi10Mg | ★★★☆☆ | Faible | 660 | Modéré | $$ |

| Inconel 718 | ★★★★★ | Haut | 1300-1400 | Excellent | $$$$ |

| Poudre de tungstène | ★★★★★ | Très élevé | 3422 | Excellent | $$$$ |

À la recherche de poudre de fabrication additive de haute qualité ? Découvrez la sélection de poudres de Heeger Materials pour matériaux AM de première qualité.

Produits apparentés

-

Poudre sphérique d'alliage à haute entropie (CoCrNi)82-Al9-Ti9 - (CoCrNi)82-Al9-Ti9 HEA - Fabrication additive - Impression 3D

-

Poudre sphérique d'alliage à haute entropie (FeCoNi)86-Al7-Ti7 - (FeCoNi)86-Al7-Ti7 HEA - Fabrication additive - Impression 3D

-

(Ni3.5Co3Cr1.5)90-Al5-Ti5 High-entropy Alloy Spherical Powder - (Ni3.5Co3Cr1.5)90-Al5-Ti5 HEA - Fabrication additive - Impression 3D

-

Poudre sphérique d'alliage Al-Co-Cr-Fe-Mo à haute entropie - Al-Co-Cr-Fe-Mo HEA - Fabrication additive - Impression 3D

Comment choisir la bonne poudre pour la fabrication additive

Sélection de la meilleure poudre AM nécessite une compréhension taille, pureté et morphologie des particules.

Critères de sélection clés

- Composition de la poudre - Choisir métaux purs ou alliages en fonction des besoins de l'application.

- Distribution de la taille des particules (PSD) - Des gammes de tailles optimisées :

- 15-45µm (LPBF, SLM)

- 45-75µm (EBM, DED, Binder Jetting)

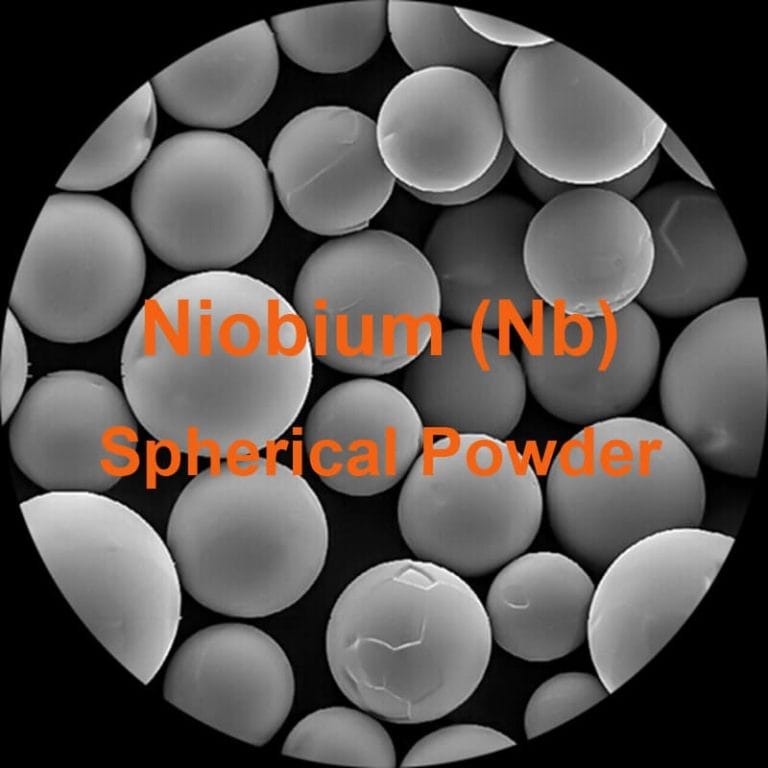

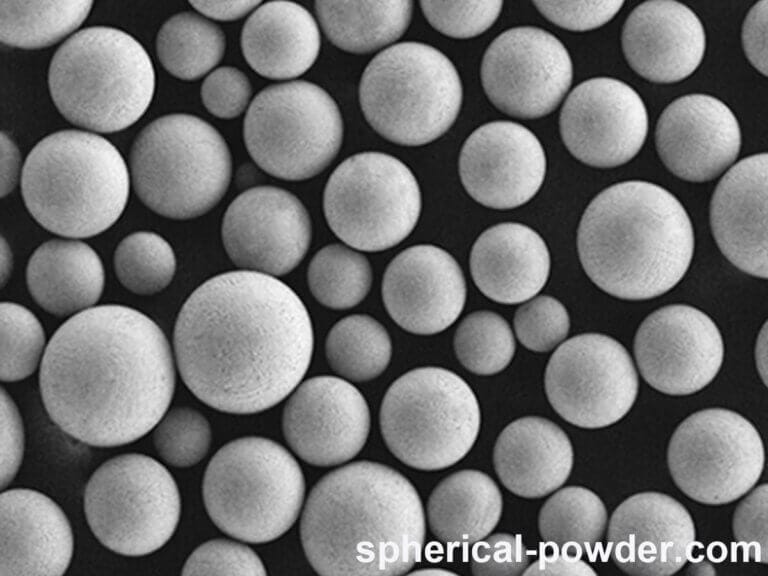

- Morphologie des poudres - Poudres sphériques offrir une meilleure fluidité et une meilleure imprimabilité.

- Pureté et teneur en oxygène - Faibles niveaux d'oxygène améliorer performance mécanique.

- Compatibilité des imprimantes - Veiller à ce que la poudre soit optimisée pour votre système AM spécifique.

Heeger Materials Inc. fournit poudres de fabrication additive personnalisées pour applications aérospatiales, médicales et industrielles.

Demande de devis pour des poudres AM de qualité supérieure.

Principaux fournisseurs de poudres pour la fabrication additive en 2025

Trouver un fournisseur fiable est cruciale pour une qualité et une répétabilité constantes en fabrication additive.

Principaux fournisseurs de poudres pour la fabrication additive

| Nom du fournisseur | Pays | Spécialisation | Méthodes de production | Site web |

|---|---|---|---|---|

| Heeger Materials Inc. | ÉTATS-UNIS | Impression 3D de poudres métalliques | VIGA, PREP, Atomisation à gaz | Visiter le site |

| Höganäs | Suède | Poudres métalliques | Atomisation de l'eau | N/A |

| Oerlikon Metco | Suisse | Poudres AM pour l'aérospatiale et le secteur médical | Atomisation des gaz | N/A |

| Sandvik | Suède | Fabrication additive | Atomisation des gaz | N/A |

Pourquoi choisir Heeger Materials ?

- plus de 40 ans d'expertise dans la métallurgie des poudres.

- Poudres sphériques de haute pureté atomisées au gaz pour AM.

- Des collaborations fortes avec instituts de recherche aérospatiale et médicale.

- Prix compétitifs et distribution mondiale.

À la recherche de poudres de fabrication additive de confiance? Contactez Heeger Materials dès aujourd'hui !

Normes de qualité pour les poudres de fabrication additive

Garantir la la plus haute qualité en fabrication additive (AM) poudre est cruciale pour une production de pièces fiable, reproductible et performante. Différentes industries, y compris l'aérospatiale, le médical et l'automobile, exiger le strict respect des normes de qualité internationales pour garantir la consistance des poudres, la fluidité et les propriétés mécaniques.

Principales normes de qualité pour les poudres destinées à la fabrication additive

| Standard | Description |

|---|---|

| ASTM F3049 | Spécification pour caractérisation des poudres métalliques dans la fabrication additive. |

| ASTM F3302 | Norme pour les les poudres métalliques utilisées dans les procédés AM de fusion sur lit de poudre (PBF). |

| ISO 52907 | Lignes directrices pour le contrôle de la qualité des poudres utilisées dans la fabrication additive. |

| AMS 4999 | Spécification des matériaux aérospatiaux pour poudres à base de titane et de nickel. |

| Conformité RoHS | Veille la sécurité environnementale en limitant les substances dangereuses. |

Pourquoi choisir une poudre certifiée pour la fabrication additive ?

- Assure l'uniformité de la taille et de la forme des particules - Essentiel pour les processus LPBF, SLM et EBM.

- Propriétés mécaniques supérieures - Réunions des exigences strictes en matière de résistance, de dureté et de stabilité thermique.

- Faible teneur en oxygène et contaminants - Poudres de haute pureté améliorer intégrité et performance des pièces.

- Conformité avec les réglementations aérospatiales et médicales - Essentiel pour les sécurité et fiabilité en industries de haute performance.

Au Heeger Materials Inc.nous fabriquons poudres AM de haute qualité qui sont conformes aux Normes ASTM, AMS et ISO, en veillant à ce que une imprimabilité et une cohérence optimales.

Analyse des coûts de la poudre de fabrication additive

Le coût de la fabrication additive poudre varie en fonction de matériau, méthode de production et demande du marché.

Facteurs clés influençant le coût de la poudre AM

- Méthode de production - Atomisation du gaz et atomisation par plasma produire des poudres sphériques de meilleure qualité, ce qui entraîne une augmentation des coûts.

- Distribution de la taille des particules (PSD) - Poudres fines (15-45µm) pour LPBF sont plus cher en raison de une plus grande précision de traitement.

- Niveaux de pureté - Faible teneur en oxygène et impuretés minimales améliorer performance mécanique mais augmentation des coûts.

- Offre et demande mondiales - Les prix fluctuent en fonction la disponibilité des matières premières et les besoins de l'industrie.

Comparaison des prix des poudres pour la fabrication additive

| Type de poudre | Coût ($/kg) | Cas d'utilisation courante |

|---|---|---|

| Titane Ti6Al4V | 250-250 – ; 250-600 | Aérospatiale, implants médicaux |

| Acier inoxydable 316L | 80-80 – ; 80-150 | Ingénierie générale, applications médicales |

| Inconel 718 | 200-200 - 200-500 | Pièces aérospatiales à haute température |

| Alliage d'aluminium AlSi10Mg | 50-50 – ; 50-120 | Automobile, structures légères |

| Poudre de tungstène | 300-300 - 300-800 | Blindage contre les radiations, aérospatiale |

Poudres de titane et d'Inconel sont plus cher en raison de forte demande dans les secteurs de l'aérospatiale et de la médecine, tandis que poudres d'acier inoxydable et d'aluminium offrir des solutions rentables pour les applications industrielles.

Demande de devis personnalisé pour la poudre AM.

Taille et forme des particules dans la fabrication additive Poudre

Le la distribution de la taille des particules (DSP) et la morphologie impact la fluidité, l'adhérence de la couche et les propriétés de la pièce finale en fabrication additive.

L'importance de la taille des particules

- Poudre fine (15-45 µm) - Meilleur pour Fusion laser sur lit de poudre (LPBF), SLM et EBM.

- Poudre moyenne (45-75 µm) - Utilisé dans Jet de liant et dépôt d'énergie directe (DED).

- Poudre grossière (75-150 µm) - Convient pour les procédés de moulage par injection de métal (MIM) et de pulvérisation à froid.

Poudre sphérique ou poudre irrégulière : quelle est la meilleure ?

| Forme de la poudre | Caractéristiques | Meilleure application |

|---|---|---|

| Sphérique | Excellente fluidité, emballage uniforme, faible porosité | Impression 3D, LPBF, SLM |

| Irrégulier | Plus faible fluidité, plus grande porosité, production moins coûteuse | Jet de liant, MIM |

Poudre d'AM sphérique atomisée par gaz est préférée pour les technologies de fusion sur lit de poudre (PBF) en raison de une meilleure fluidité, une densité plus élevée et une réduction des défauts.

Découvrez nos poudres métalliques sphériques de haute qualité.

Méthodes de production de poudre pour la fabrication additive

Différents les méthodes de production de poudres l'impact sur la la forme, la pureté et le coût des particules de Poudres AM.

Comparaison des méthodes de production de poudres

| Méthode de production | Forme des particules | La pureté | Coût | Meilleur cas d'utilisation |

|---|---|---|---|---|

| Atomisation gazeuse (GA) | Sphérique | Haut | $$$ | impression 3DAéronautique et espace |

| Atomisation par plasma (PA) | Hautement sphérique | Très élevé | $$$$ | Médical, aérospatial |

| Atomisation de l'eau (WA) | Irrégulier | Modéré | $$ | Jet de liant, MIM |

| PREP (Plasma Rotating Electrode Process) | Extrêmement sphérique | Ultra-haut | $$$$$ | Applications aérospatiales et médicales à haute performance |

Atomisation par gaz et atomisation par plasma sont les méthodes les plus largement utilisées pour Poudre AM, en veillant à ce que excellente pureté, sphéricité et imprimabilité.

Heeger Materials Inc. se spécialise dans poudres AM atomisées par gaz et par plasmaet de fournir des services de qualité supérieure qualité et cohérence.

FAQ sur la poudre de fabrication additive

| Question | Réponse |

|---|---|

| À quoi sert la poudre de fabrication additive ? | Il est utilisé dans applications aérospatiales, médicales, automobiles et industrielles pour pièces complexes à haute résistance. |

| Quelle est la meilleure poudre AM pour les implants médicaux ? | Titane Ti6Al4V et acier inoxydable 316L en raison de biocompatibilité et résistance à la corrosion. |

| Quelle est la différence entre une poudre atomisée au gaz et une poudre atomisée à l'eau ? | Poudres atomisées sous gaz sont sphérique avec une meilleure fluidité, tandis que poudres atomisées à l'eau sont irrégulière et moins chère. |

| Quelle est la taille typique des particules des poudres AM ? | 15-45µm pour LPBF/SLM, 45-75µm pour Jets de liant et DED. |

| Où puis-je acheter de la poudre de fabrication additive de haute qualité ? | Heeger Materials Inc. fournit une prime Poudres AM pour les applications industrielles. |

Conclusion

Poudre de fabrication additive révolutionne fabrication en permettant des conceptions légères, très résistantes et complexes. Avec les progrès réalisés dans le domaine de la métallurgie des poudres et impression 3DLes secteurs d'activité tels que l'agriculture, la pêche, l'élevage et l'agriculture biologique sont également concernés. l'aérospatiale, le médical et l'automobile adoptent rapidement technologies d'AM des métaux.

Pour poudre de fabrication additive de haute qualité, Heeger Materials Inc. offres poudres sphériques de haute pureté produit à l'aide de techniques d'atomisation avancées.

Vous recherchez une poudre AM de qualité supérieure ? Contactez-nous dès aujourd'hui !

.jpg)