Poudre d'alliage à haute entropie 2025 : Propriétés, applications et aperçu du marché

Vue d'ensemble de la poudre d'alliage à haute enthropie

Poudre d'alliage à haute entropie (HEA) est un matériau de pointe composé de plusieurs éléments principaux dans des rapports atomiques presque égauxce qui se traduit par résistance mécanique, stabilité thermique et résistance à la corrosion exceptionnelles. Contrairement aux alliages traditionnels, qui reposent sur un seul élément dominant, les HEA tirent parti de l'effet de levier de la technologie. synergie de plusieurs métaux pour atteindre propriétés supérieures.

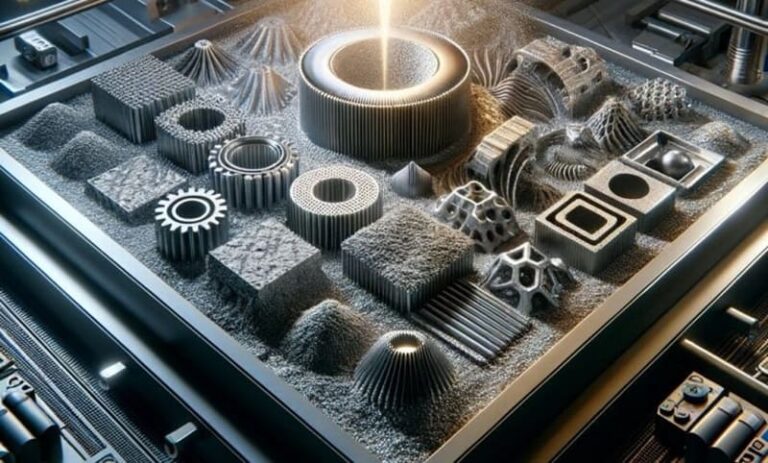

En raison de leur dureté élevée, excellente résistance à l'oxydation et résistance exceptionnelle à l'usure, poudres d'alliages à haute entropie sont largement utilisés dans les l'aérospatiale, la défense, le biomédical, l'énergie et la fabrication additive (impression 3D).

Au Heeger Materials Inc.Nous fournissons poudres d'alliage de haute pureté, atomisées au gaz et à haute entropie, en veillant à ce que des performances optimales pour les applications industrielles de pointe.

Pourquoi choisir la poudre d'alliage à haute entropie ?

Les alliages à haute entropie sont révolutionner la science des matériaux en offrant une solidité, une stabilité et une polyvalence inégalées pour les applications extrêmes.

Principaux avantages de la poudre d'alliage à haute enthropie

- Résistance mécanique supérieure - Exposition HEAs dureté élevée, résistance à l'usure et ténacitéet surpasse les alliages conventionnels.

- Excellente stabilité thermique - Maintient intégrité structurelle à des températures extrêmesil s'agit donc d'une solution idéale pour applications aérospatiales et énergétiques.

- Résistance exceptionnelle à la corrosion et à l'oxydation - Convient pour les environnements difficiles, y compris les industries marines et chimiques.

- Composition sur mesure - Permet personnalisation des propriétés en fonction des besoins de l'application.

- Des performances accrues pour la fabrication additive - Les AES sont largement utilisées dans Impression 3D et technologies de fabrication avancées.

À la recherche de poudre HEA haute performance ? Découvrez la sélection de Heeger Materials.

Meilleures compositions de poudres d'alliages à haute entropie pour différentes applications

Les poudres de HEA sont classées en fonction de composition élémentaire, application et méthode de traitement.

Comparaison des poudres d'alliages à haute enthropie les plus courantes

| Composition de l'alliage | Propriétés principales | Meilleures applications |

|---|---|---|

| CoCrFeNiMn | Haute résistance, résistance à la corrosion | Aérospatiale, marine, biomédical |

| AlCoCrFeNi | Stabilité à haute température, résistance à l'oxydation | Aubes de turbines, échangeurs de chaleur |

| MoNbTaW | Résistance aux températures très élevées, dureté | Aérospatiale, réacteurs nucléaires |

| TiVZrNbHf | Légèreté, ductilité élevée, biocompatibilité | Implants médicaux, matériaux structurels |

| NiCrCoFeMo | Résistance à l'usure, excellente résistance mécanique | Outils de coupe, revêtements |

AES MoNbTaW sont préférés pour applications à haute température, tandis que TiVZrNbHf HEAs sont largement utilisés dans applications biomédicales et structurelles.

Demander un devis personnalisé pour les poudres HEA.

Produits apparentés

-

Poudre sphérique d'alliage à haute entropie (CoCrNi)94-Al3-Ti3 - (CoCrNi)94-Al3-Ti3 HEA - Fabrication additive - Impression 3D

-

Poudre sphérique d'alliage à haute entropie (FeCoNi)86-Al7-Ti7 - (FeCoNi)86-Al7-Ti7 HEA - Fabrication additive - Impression 3D

-

(Ni3.5Co3Cr1.5)90-Al5-Ti5 High-entropy Alloy Spherical Powder - (Ni3.5Co3Cr1.5)90-Al5-Ti5 HEA - Fabrication additive - Impression 3D

-

Poudre sphérique d'alliage Al-Co-Cr-Fe-Mo à haute entropie - Al-Co-Cr-Fe-Mo HEA - Fabrication additive - Impression 3D

Applications industrielles de la poudre d'alliage à haute entropie

Les poudres de HEA sont utilisées dans applications de haute performance qui requièrent durabilité extrême, stabilité thermique et propriétés mécaniques supérieures.

Principales applications industrielles de la poudre de HEA

| L'industrie | Application | Avantages |

|---|---|---|

| Aérospatiale et défense | Composants de moteurs à réaction, boucliers thermiques | Rapport résistance/poids élevé, résistance aux températures extrêmes |

| Biomédical et santé | Implants chirurgicaux, prothèses | Biocompatibilité, résistance à la corrosion |

| Énergie et nucléaire | Composants de réacteurs nucléaires, matériaux de fusion | Résistance aux radiations, stabilité thermique |

| Fabrication additive (AM) | Pièces haute performance imprimées en 3D | Haute précision, géométries complexes |

| Revêtements résistants à l'usure | Revêtements durs, outils de coupe | Dureté supérieure, durée de vie prolongée |

Avec la la demande croissante de matériaux à haute résistance et résistants à la corrosion, poudres d'alliages à haute entropie sont en train de devenir rapidement une changer la donne dans les industries de pointe.

Découvrez nos poudres de HEA de haute pureté.

Taille et forme des particules dans les poudres d'alliages à haute enthropie

Le la distribution de la taille des particules (DSP) et la morphologie impact la fluidité, le comportement au frittage et la qualité du produit final en Impression 3D, revêtements et applications structurelles.

Taille optimale des particules pour les applications de poudre de HEA

| Gamme de taille des particules | Meilleure application |

|---|---|

| 0,5-10 µm | Revêtements haute performance, applications catalytiques |

| 10-45 µm | Implants biomédicaux, électronique avancée |

| 45-150 µm | Impression 3D, composants aérospatiaux |

Poudre d'alliage sphérique ou irrégulière à haute enthropie : quelle est la meilleure solution ?

| Forme de la poudre | Caractéristiques | Meilleure application |

|---|---|---|

| Sphérique | Grande fluidité, emballage uniforme, frittage amélioré | Impression 3D, aérospatiale, applications médicales |

| Irrégulier | Surface plus importante, porosité accrue | Revêtements, traitement chimique, matériaux résistants à l'usure |

Poudres HEA sphériques sont préférés pour fabrication additive, tandis que poudres irrégulières sont utilisés dans revêtements et procédés chimiques.

Découvrez nos poudres HEA optimisées.

Normes de qualité pour les poudres d'alliages à haute entropie

Veiller à ce que fiabilité, cohérence et performances supérieuresLes poudres d'alliage à haute entropie (HEA) doivent répondre aux critères suivants des normes internationales strictes la réglementation de leur pureté, composition, microstructure et propriétés mécaniques. Ces normes sont essentielles pour les applications dans les domaines suivants l'aérospatiale, la médecine, la défense et la fabrication additive (AM).

Principales normes de qualité pour les poudres d'alliages à haute entropie

| Standard | Description |

|---|---|

| ASTM F3318 | Spécification pour les poudres métalliques, y compris les HEA, utilisées dans la fabrication additive. |

| ASTM B214 | Norme pour les analyse granulométrique des poudres métalliques. |

| ISO 22068 | Norme internationale pour les HEAs utilisés dans des applications à haute température. |

| AMS 4999 | Spécification des matériaux aérospatiaux pour alliages à haute entropie dans les moteurs à turbine. |

| Conformité RoHS et REACH | Veille sécurité environnementale et restriction des substances dangereuses. |

Pourquoi choisir la poudre d'alliage certifiée à haute entropie ?

- Garantit une pureté et une performance optimales - Garanties stabilité thermique et résistance mécanique élevées.

- Essentiel pour l'aérospatiale et le secteur médical - Réunions des réglementations strictes pour des environnements très performants.

- Optimisé pour la fabrication additive - Garantit une fluidité et une imprimabilité constantes des poudres.

- Conformité mondiale - Adhère à normes internationales pour les applications des matériaux avancés.

Au Heeger Materials Inc., notre poudres de HEA de haute pureté respecter Normes ASTM, ISO et AMS, en veillant à ce que une qualité et une fiabilité exceptionnelles.

Analyse des coûts de la poudre d'alliage à haute entropie

Le prix des poudre d'alliage à haute entropie est influencée par divers facteurs, notamment composition des éléments, méthode de production, taille des particules et demande du marché. Étant donné que les EES intègrent plusieurs métaux à haute performanceIls sont souvent plus cher que les alliages traditionnels.

Facteurs influençant le coût des poudres d'alliages à haute entropie

- Composition élémentaire - Les HEA contenant des éléments rares comme le hafnium, le rhénium et le tantale sont nettement plus chers.

- Méthode de production - L'atomisation au gaz et l'atomisation au plasma augmentent les coûts par rapport au broyage mécanique..

- Distribution de la taille des particules (PSD) - Les poudres plus fines (5-50 µm) destinées à l'impression 3D nécessitent un traitement avancé, ce qui augmente les coûts.

- Demande du marché et tendances de l'industrie - Les prix fluctuent en raison utilisation croissante dans les secteurs de l'aérospatiale, de l'énergie et de la biomédecine.

Comparaison des prix des poudres d'alliages à haute enthropie

| Type d'alliage à haute entropie | Coût ($/kg) | Cas d'utilisation courante |

|---|---|---|

| Poudre CoCrFeNiMn HEA | 200-200 - 200-800 | Aérospatiale, revêtements résistants à la corrosion |

| Poudre AlCoCrFeNi HEA | 500-500 - 500-1,500 | Aubes de turbines, échangeurs de chaleur |

| MoNbTaW HEA Poudre | 1,500-1,500 - 1,500-4,000 | Applications nucléaires, températures extrêmes |

| TiVZrNbHf Poudre HEA | 1,000-1,000 - 1,000-3,000 | Matériaux biomédicaux et structurels |

| Poudre NiCrCoFeMo HEA | 700-700 - 700-2,500 | Revêtements résistants à l'usure, outils de coupe |

AES MoNbTaW dominer applications à haute température, tandis que CoCrFeNiMn HEAs sont largement utilisés dans applications marines et aérospatiales.

Demander un devis pour les poudres HEA.

Méthodes de production de poudre d'alliage à haute entropie

Différents techniques de production de poudres impact morphologie, pureté et coût des particulesIl est donc essentiel de sélectionner les la bonne méthode pour l'application prévue.

Comparaison des méthodes de production de poudres d'alliages à haute entropie

| Méthode de production | Forme des particules | La pureté | Coût | Meilleur cas d'utilisation |

|---|---|---|---|---|

| Alliages mécaniques (MA) | Irrégulier | Modéré | $$ | Revêtements résistants à l'usure, applications de frittage |

| Atomisation gazeuse (GA) | Sphérique | Haut | $$$ | Impression 3D, pièces aérospatiales |

| Atomisation par plasma (PA) | Hautement sphérique | Ultra-haut | $$$$ | Applications médicales, AM de haute précision |

| Fusion par induction sous vide (VIM) | Dendritique ou sphérique | Très élevé | $$$ | Superalliages, applications aérospatiales |

Poudres de HEA atomisées au gaz et traitées au plasma sont préférés pour fabrication additive et aérospatiale, en veillant à ce que une fluidité et une imprimabilité supérieures.

Heeger Materials Inc. se spécialise dans poudres d'alliage de haute pureté à haute entropie atomisées au gaz pour applications industrielles de pointe.

FAQ sur la poudre d'alliage à haute entropie

| Question | Réponse |

|---|---|

| À quoi sert la poudre d'alliage à haute entropie ? | Les AES sont utilisées dans l'aérospatiale, l'énergie, les implants médicaux, les revêtements et l'impression 3D. |

| Pourquoi les alliages à haute entropie sont-ils meilleurs que les alliages traditionnels ? | Les HEAs offrent une plus grande résistance, une meilleure stabilité thermique et une meilleure résistance à la corrosion en raison de leur composition multiélémentaire. |

| Quelle est la meilleure composition de HEA pour les applications aérospatiales ? | AES en AlCoCrFeNi et MoNbTaW fournir stabilité à haute température et résistance à l'oxydationils sont donc idéaux pour moteurs à réaction et aubes de turbine. |

| Comment la poudre HEA se compare-t-elle aux alliages de titane ? | Les HEA peuvent être plus solide, plus résistant à la corrosion et plus stable sur le plan thermique que les alliages de titane, en fonction de la composition. |

| Où puis-je acheter de la poudre d'HEA de haute pureté ? | Heeger Materials Inc. fournit une prime Poudres HEA pour applications industrielles. |

Conclusion

Poudre d'alliage à haute entropie révolutionne la science des matériaux en offrant résistance mécanique, résistance à la corrosion et stabilité thermique supérieures pour les applications aérospatiales, médicales, énergétiques et de fabrication additive.

Pour poudres HEA de qualité supérieure, Heeger Materials Inc. fournit des solutions sur mesure avec des poudres sphériques de haute pureté atomisées au gaz.

Vous recherchez de la poudre d'alliage à haute entropie de première qualité ? Contactez-nous dès aujourd'hui !

.jpg)