Thermal Spraying 2025: The Ultimate Guide to Coating Technologies and Materials

Overview

Thermal spraying is an advanced surface coating process that applies metal, ceramic, or composite powders onto a substrate using high-energy thermal techniques such as plasma spraying, flame spraying, HVOF (High-Velocity Oxygen Fuel), and cold spraying. This process enhances wear resistance, corrosion resistance, heat resistance, and electrical conductivity, making it an essential technology in aerospace, automotive, medical, and energy industries.

As manufacturers seek superior coatings for extreme environments, thermal spraying has become an indispensable solution, offering high-performance coatings for engine components, turbine blades, biomedical implants, and industrial machinery.

Why Choose Thermal Spraying for Coatings?

Thermal spraying provides superior protective coatings compared to electroplating, anodizing, and painting due to its high deposition rate, strong adhesion, and ability to coat large surfaces.

Key Benefits

- Enhanced Wear Resistance – Protects against abrasion, erosion, and impact damage.

- Superior Corrosion Protection – Ideal for marine, aerospace, and industrial environments.

- High-Temperature Resistance – Essential for gas turbines, exhaust systems, and heat exchangers.

- Customizable Material Selection – Supports metals, ceramics, composites, and polymers.

- Minimal Heat Distortion – Unlike welding, thermal spraying does not cause warping or structural changes.

Looking for high-performance thermal spraying powders? Explore Heeger Materials’ selection.

Types

Different thermal spraying techniques vary in temperature, velocity, and coating quality, making each suitable for specific applications.

Comparison

| Spraying Method | Process Temperature | Coating Adhesion | Best Applications |

|---|---|---|---|

| Plasma Spraying (APS, VPS) | 10,000–15,000°C | Strong | Aerospace, biomedical implants, high-temperature coatings |

| High-Velocity Oxygen Fuel (HVOF) | 2,500–3,000°C | Very Strong | Wear-resistant coatings, turbine blades, aerospace components |

| Cold Spraying | Below 800°C | Moderate | Aluminum, copper coatings, electronics, corrosion-resistant coatings |

| Flame Spraying | 2,500–3,000°C | Moderate | Large-scale coatings, industrial machinery protection |

| Arc Spraying | 5,000–6,000°C | Strong | Corrosion protection, structural components |

HVOF and plasma spraying are the most widely used methods for aerospace, medical, and industrial applications, delivering high-density coatings with excellent adhesion.

Find the best powder for your thermal spraying process.

Related Products

-

13Cr-5Al-0.5Y Alloy Spherical Powder for Thermal Spraying – 13Cr-5Al-0.5Y Powder – Additive Manufacturing – 3D Printing

-

9Cr-13Al-0.5Y Alloy Spherical Powder for Thermal Spraying – 9Cr-13Al-0.5Y Powder – Additive Manufacturing – 3D Printing

-

Fe13Cr5Al1Ti0.1Y Alloy Spherical Powder for Thermal Spraying – Fe13Cr5Al1Ti0.1Y Powder – Additive Manufacturing – 3D Printing

-

Ni-Al-Co-Cr-Si-Y Alloy Spherical Powder for Thermal Spraying – Ni-Al-Co-Cr-Si-Y Powder – Additive Manufacturing – 3D Printing

Best Materials

Choosing the right thermal spraying powder depends on application requirements, environmental conditions, and coating performance.

Common

| Material Type | Key Benefits | Common Applications |

|---|---|---|

| Nickel-Based Alloys (Inconel 625, 718) | High-temperature resistance, corrosion protection | Aerospace, power generation |

| Cobalt-Based Alloys (Stellite 6, 21) | Wear and oxidation resistance | Medical implants, cutting tools |

| Tungsten Carbide (WC-Co, WC-Ni) | Extreme hardness, wear-resistant | Turbine blades, pump components |

| Aluminum & Zinc Powders | Corrosion protection, lightweight | Marine, automotive, infrastructure |

| Chromium Carbide (Cr3C2-NiCr) | High-temperature oxidation resistance | Jet engines, chemical plants |

| Ceramic Powders (Alumina, Zirconia, YSZ) | Thermal barrier coatings, electrical insulation | Gas turbines, biomedical, electronics |

Nickel-based and tungsten carbide coatings dominate high-temperature and wear-resistant applications, while ceramic coatings provide thermal insulation for aerospace and industrial equipment.

Request a quote for premium thermal spraying powders.

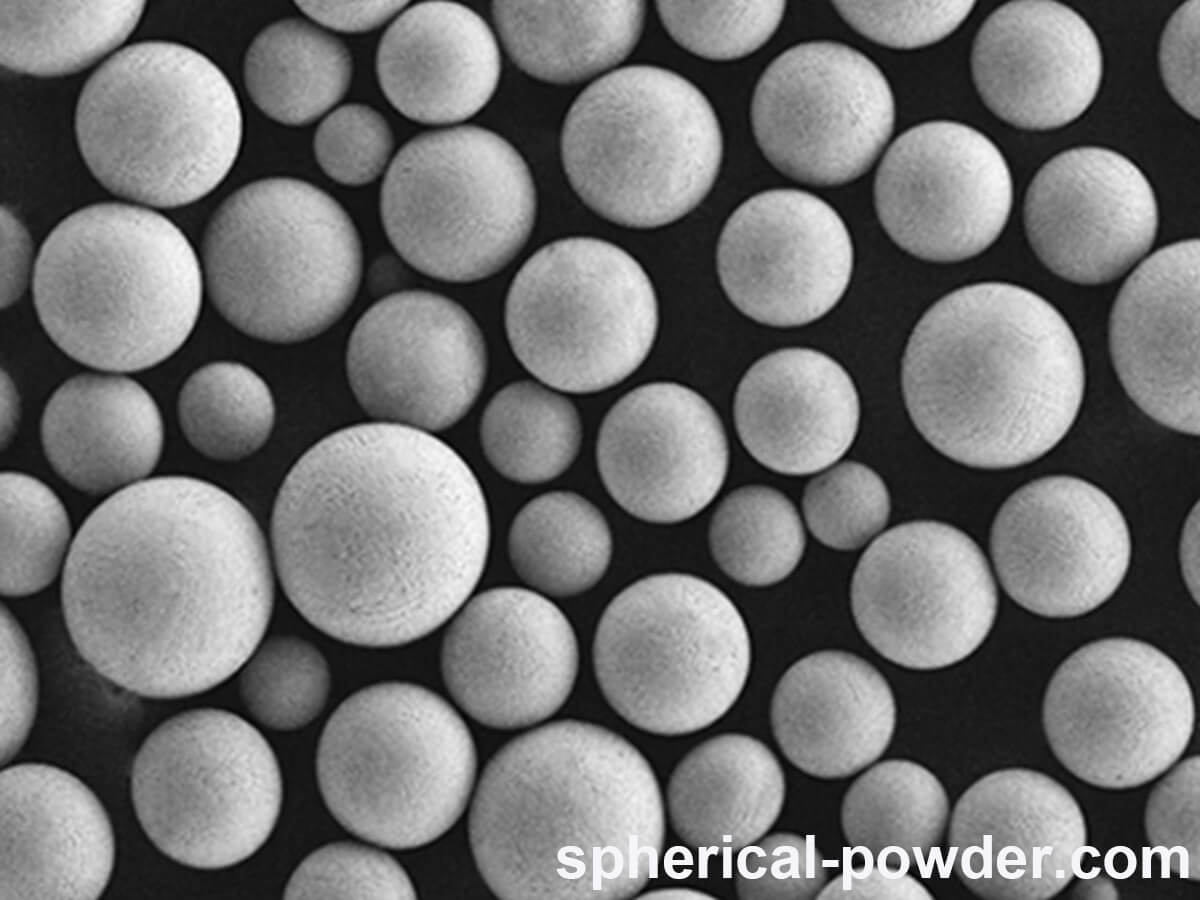

Particle Size and Shape

The particle size distribution (PSD) and morphology play a key role in coating density, adhesion, and performance in thermal spraying applications.

Optimal Particle Size

| Particle Size Range | Best Application |

|---|---|

| 5-25 µm | Plasma Spraying (APS, VPS) |

| 15-45 µm | HVOF, Flame Spraying |

| 45-75 µm | Cold Spraying, Arc Spraying |

Spherical vs. Irregular Powder: Which is Better?

| Powder Shape | Characteristics | Best Application |

|---|---|---|

| Spherical | Excellent flowability, uniform packing, high adhesion | HVOF, Plasma Spraying |

| Irregular | Lower flowability, rougher coatings, lower cost | Flame Spraying, Arc Spraying |

Spherical powders are preferred for thermal spraying, ensuring better flowability, uniform coating, and minimal defects.

Explore our high-quality spherical thermal spraying powders.

Top Suppliers in 2025

Finding a reliable supplier is crucial for consistent coating quality and performance in thermal spraying applications.

Leading Suppliers

| Supplier Name | Country | Specialization | Production Methods | Website |

|---|---|---|---|---|

| Heeger Materials Inc. | USA | Thermal Spraying Metal Powders | VIGA, PREP, Gas Atomization | Visit Site |

| Höganäs | Sweden | Metal & Ceramic Powders | Water Atomization | N/A |

| Oerlikon Metco | Switzerland | Aerospace & Industrial Coatings | Gas Atomization | N/A |

| Sandvik | Sweden | Hardfacing & Wear-Resistant Powders | Gas Atomization | N/A |

Looking for high-performance thermal spraying powders? Contact Heeger Materials today!

Quality Standards

Ensuring high-quality thermal spraying powders is essential for optimal coating performance, adhesion, and durability. Various international standards govern the composition, particle size, flowability, and purity of these powders to meet aerospace, medical, and industrial requirements.

Key Quality Standards

| Standard | Description |

|---|---|

| ASTM B214 | Standard for particle size distribution analysis of metal powders. |

| ASTM C633 | Test method for adhesion strength of thermal spray coatings. |

| ISO 14922 | Guidelines for thermal spraying process qualification. |

| AMS 4775 | Aerospace Material Specification for nickel-based thermal spray powders. |

| ISO 14923 | Standard for quality assessment of thermal spray coatings. |

| RoHS Compliance | Ensures environmental safety by restricting hazardous substances. |

Why Choose Certified Thermal Spraying Powders?

- Ensures Uniform Particle Size & Shape – Provides consistent spray deposition.

- Superior Coating Properties – Meets strict adhesion, wear resistance, and thermal stability requirements.

- Low Oxygen & Contaminants – High-purity powders improve coating integrity and performance.

- Compliance with Aerospace & Medical Regulations – Ensures safety and reliability in critical applications.

At Heeger Materials Inc., we manufacture high-purity thermal spraying powders that comply with ASTM, AMS, and ISO standards, ensuring optimal spray performance and durability.

Cost Analysis

The price of thermal spraying powders depends on material type, particle size, and production method.

Factors Affecting Thermal Spraying Powder Cost

- Base Material Composition – High-performance alloys (Nickel, Cobalt, Tungsten Carbide) cost more than Aluminum or Zinc-based powders.

- Production Method – Gas atomization and plasma atomization produce higher-quality spherical powders, increasing costs.

- Particle Size Distribution (PSD) – Finer powders (5-25µm) for Plasma Spraying are more expensive due to higher precision requirements.

- Purity & Oxygen Content – Lower oxygen levels improve coating performance but increase costs.

- Global Supply & Demand – Prices fluctuate based on raw material availability and industry needs.

Price Comparison

| Powder Type | Cost ($/kg) | Common Use Case |

|---|---|---|

| Nickel-Based Alloy (Inconel 625, 718) | 200−200 – 200−600 | Aerospace, gas turbines |

| Cobalt-Based Alloy (Stellite 6, 21) | 250−250 – 250−700 | Medical implants, wear-resistant coatings |

| Tungsten Carbide (WC-Co, WC-Ni) | 400−400 – 400−1,000 | High-wear applications, turbine blades |

| Chromium Carbide (Cr3C2-NiCr) | 300−300 – 300−800 | High-temperature corrosion resistance |

| Aluminum & Zinc Powders | 50−50 – 50−150 | Corrosion protection, marine coatings |

Nickel-based and tungsten carbide powders are more expensive due to their high-performance applications, while aluminum and zinc powders offer cost-effective corrosion protection.

Request a custom quote for bulk orders.

Production Methods

Different powder production methods impact the particle shape, purity, and cost of thermal spraying powders.

Comparison of Powder Production Methods

| Production Method | Particle Shape | Purity | Cost | Best Use Case |

|---|---|---|---|---|

| Gas Atomization (GA) | Spherical | High | $$$ | HVOF, Plasma Spraying |

| Plasma Atomization (PA) | Highly Spherical | Very High | $$$$ | Medical, Aerospace |

| Water Atomization (WA) | Irregular | Moderate | $$ | Flame Spraying, Arc Spraying |

| PREP (Plasma Rotating Electrode Process) | Extremely Spherical | Ultra-High | $$$$$ | High-performance aerospace & medical applications |

Gas atomization and plasma atomization are the most widely used methods for thermal spraying powders, ensuring excellent purity, sphericity, and coating performance.

Heeger Materials Inc. specializes in gas-atomized and plasma-atomized thermal spraying powders, delivering superior quality and consistency.

FAQ

| Question | Answer |

|---|---|

| What is it used for? | It is used for protective coatings, wear resistance, corrosion resistance, and thermal insulation in aerospace, medical, marine, and industrial applications. |

| What is the best thermal spraying method for wear resistance? | HVOF and plasma spraying are ideal for wear-resistant coatings such as tungsten carbide and Stellite alloys. |

| What is the difference between HVOF and plasma spraying? | HVOF produces dense, high-adhesion coatings, while plasma spraying is better for high-melting-point materials like ceramics. |

| What is the typical particle size for them? | 5-25µm for plasma spraying, 15-45µm for HVOF, and 45-75µm for cold spraying. |

| Where can I buy high-quality thermal spraying powder? | Heeger Materials Inc. provides premium thermal spraying powders for industrial applications. |

Conclusion

It is a cutting-edge surface coating technology, offering superior wear resistance, corrosion protection, and high-temperature resistance for critical components in various industries.

For top-quality thermal spraying powders, Heeger Materials Inc. provides tailored solutions with high-purity, gas-atomized spherical powders.

Looking for premium thermal spraying powder? Contact us today!