Nano Alumina in Ceramic Processing: How Low-Temperature Conditioning Shapes Its Performance

Low-temperature conditioning has become a crucial strategy for controlling the microstructure, reactivity, and phase evolution of nano alumina, especially for ceramic processing applications that rely on precision powder engineering. Nano alumina behaves differently from conventional alumina because its extremely small particle size amplifies surface energy, defect density, and phase sensitivity. As a result, even small shifts in calcination temperature can change its adsorptive activity, sintering behavior, catalytic performance, and structural stability.

This article explores how low-temperature treatment modifies nano alumina during ceramic processing, why these changes matter for industries such as structural ceramics, coatings, membranes, and catalysts, and what mechanisms drive transformations from transitional phases to α-Al2O3. Through data-supported comparisons, structured sections, and logically connected explanations, this guide provides a technical yet practical reference for researchers and ceramic engineers.

Au Technologie avancée des poudres, we specialize in high-quality ceramic powder products, ensuring optimal performance for industrial and scientific applications.

What Is Nano Alumina and Why Is It Sensitive to Low-Temperature Conditioning?

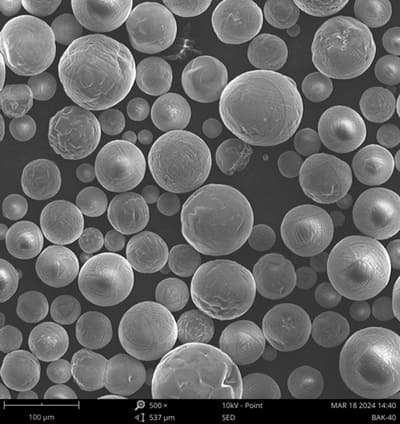

Nano alumina refers to aluminum oxide with particle sizes typically below 100 nm, displaying high surface area and abundant defect sites. These features make it highly responsive to temperature, especially in the 550–850°C range, where transitional phases evolve without aggressive sintering.

Before presenting data, it is important to clarify that nano alumina exists in multiple metastable forms (γ, δ, θ) before transforming to the stable α phase. The temperature window for transformation varies depending on precursor chemistry, additives, and heating rate.

Common Characteristics of Nano Alumina Forms

| Alumina Phase | Typical Formation Temperature | Taille des particules | Key Features |

| γ-Al2O3 | 400–750°C | 5–10 nm | High surface area, porous, catalytic activity |

| α/γ mixture | 750–850°C | 20–30 nm | Balanced strength and reactivity |

| α-Al2O3 (low-temp) | 550–600°C (special precursors) | <20 nm | High stability, high defect density |

| α-Al2O3 (traditional) | >1100°C | 30–100 nm | Thermodynamic stability |

Low-temperature sensitivity matters because it determines the final ceramic microstructure, including sintering activity, densification temperature, grain size evolution, and mechanical reliability.

Découvrez nos produits de haute qualité alumina poudre produits.

How Does Low-Temperature Conditioning Influence the Microstructure of Nano Alumina?

Low-temperature calcination significantly affects crystal nucleation, grain boundary mobility, and defect formation. When temperatures range between 550 and 850°C—as demonstrated in multiple experimental studies—nano alumina retains short-range disorder and abundant oxygen vacancies that improve reactivity for subsequent ceramic processes.

Microstructural Evolution Under Low Temperature

| Conditioning Temperature | Observed Microstructure | Implications for Ceramics |

| 550–600°C | Ultra-fine α nuclei <20 nm, high defects | Improved adsorption, higher reactivity |

| ~700°C | γ-alumina, 7–8 nm, porous | Ideal for coatings and catalyst supports |

| 750–850°C | α/γ mixed phases, 20–25 nm | Balanced sintering and mechanical performance |

| >1000°C | Fully transformed α phase, 35+ nm | Higher strength but lower surface area |

Low-temperature ranges prevent excessive grain growth, enabling nano alumina to maintain reactivity and manage phase transitions more flexibly during ceramic manufacturing.

How Does Low-Temperature Treatment Affect Phase Transformation Behavior in Nano Alumina?

Phase transformation in nano alumina is strongly dependent on precursor type and thermal pathway. Some precursors—such as aluminum–urea complexes—can produce stable α-Al2O3 at temperatures as low as 550–600°C, bypassing the high-temperature lattice rearrangements required in conventional calcination.

Factors That Shift Phase Transformation Temperature

| Facteur | Effect on Phase Transformation | Explanation |

| Precursor chemistry | ↓ Transformation temperature | Reactive intermediates form α nuclei early |

| Additives (e.g., OPT dispersant) | ↑ Transformation temperature (200–400°C) | Inhibit agglomeration, stabilize metastable phases |

| Heating rate | Faster → higher transition point | Limited diffusion prevents rearrangement |

| Particle confinement | Stabilizes γ or δ phases | Surface energy dominates lattice energy |

This flexibility is highly valuable in ceramic processing, where controlling the timing of α-phase formation determines sintering kinetics and final mechanical reliability.

In What Ways Does Low-Temperature Conditioning Modify Surface Chemistry and Reactivity?

Surface chemistry is crucial for ceramic slurry dispersion, binder interaction, and sintering reactivity. Low-temperature treated nano alumina maintains high defect density and large specific surface area, making it more chemically active.

Measured Surface Reactivity Changes

| Sample Type | Température | Surface Area (m²/g) | Reactivity Indicator |

| γ-Al2O3 | ~700°C | 200–300 | Highly adsorptive |

| α/γ mix | 750–850°C | 120–180 | Balanced activity |

| Low-temp α-Al2O3 | 550–600°C | 80–150 | Defect-driven reactivity |

| High-temp α-Al2O3 | >1100°C | <20 | Low activity |

Experiments show that low-temperature α-Al2O3 adsorbs dyes such as Congo Red at up to 1.8× the capacity of high-temperature α-phase due to its defect-rich surface. These properties directly influence how nano alumina behaves in ceramic shaping, drying, and sintering.

Why Is Low-Temperature Nano Alumina Beneficial for Ceramic Processing Workflows?

In ceramic fabrication, powder reactivity governs densification temperature, grain uniformity, shrinkage behavior, and final strength. Because low-temperature nano alumina retains fine particle size and metastable defects, it improves these parameters without requiring aggressive high-temperature firing.

Benefits of Ceramic Processing

- Faster initial sintering

- Lower energy consumption

- Enhanced packing homogeneity

- Improved interface bonding in composites

Performance Benefits Summary

| Processing Stage | Improvement from Low-Temp Nano Alumina |

| Slurry preparation | Better dispersion and stability |

| Green body formation | More uniform packing |

| Sintering | Lower onset temperature, faster diffusion |

| Final microstructure | Finer grains, better mechanical consistency |

These advantages are particularly useful in technical ceramics, membranes, transparent alumina, and electronic substrates.

How Do Different Types of Nano Alumina Compare in Ceramic Applications?

Different alumina phases and morphologies provide different strengths, making phase selection critical.

Comparison of Nano Alumina Forms in Ceramics

| Propriété | γ-Al2O3 | α/γ Mix | Low-Temp α-Al2O3 | High-Temp α-Al2O3 |

| Surface area | Highest | Haut | Modéré | Faible |

| Sintering reactivity | Haut | Moderate-high | Haut | Faible |

| Mechanical strength | Faible | Moyen | Haut | Highest |

| Energy requirement | Faible | Low-medium | Faible | Haut |

Low-temperature conditioned α/γ mixtures are particularly useful because they combine sintering responsiveness with structural stability.

Request a custom quote for our alumina powder products.

How Does Low-Temperature Nano Alumina Compare With Other Processing Methods?

Ceramic processors often debate whether low-temperature treated powders outperform conventional high-temperature calcination or hydrothermal synthesis. While each technique has strengths, low-temperature conditioning enables unique control of microstructure and phase balance.

Comparison Across Processing Routes

| Processing Method | Avantages | Limitations |

| Low-temp conditioning | Fine size, phase flexibility, high reactivity | Requires precursor control |

| High-temp calcination | Structural stability | Grain coarsening, lost reactivity |

| Hydrothermal synthesis | Uniform morphology | Lower phase stability |

| Sol–gel | Excellent purity | Expensive, slow |

Low-temperature conditioning stands out because it optimizes reactivity without sacrificing phase tunability.

What Are the Future Trends for Low-Temperature Nano Alumina in Ceramic Processing?

Emerging research trends emphasize energy reduction, microstructure precision, and nano-scale phase engineering. Low-temperature strategies are expected to integrate with advanced digital manufacturing and eco-efficient ceramic processes.

Key Future Developments

- Controlled formation of α nuclei below 550°C

- Additive-controlled metastable phase retention

- Integration into 3D-printed alumina systems

- Atomic-scale modeling of low-temp nucleation

- Low-energy optical and electronic ceramics

The ability to tune phase behavior with minimal heat input will become increasingly valuable as ceramic manufacturing moves toward sustainability and precision design.

FAQ

| Question | Réponse |

| Does low-temperature nano alumina improve sintering? | Yes, it lowers the onset temperature and increases diffusion rates. |

| Is γ-Al2O3 preferable for structural ceramics? | No, but it is excellent for coatings and catalysis. |

| Can α-phase form at 550–600°C? | Yes, with specific precursors such as aluminum–urea complexes. |

| Does low-temp treatment affect porosity? | It increases porosity in transitional phases but decreases it in the α-phase. |

| Can additives delay phase transition? | Yes, dispersants can raise the transformation temperature by 200–400°C. |

Conclusion

Low-temperature conditioning profoundly influences the phase, microstructure, and functional behavior of nano alumina in ceramic processing. By controlling temperature within strategically selected windows, engineers can design powders with optimized reactivity, tailored phase compositions, and improved sintering performance. These advantages lower production costs, enhance material quality, and support advanced ceramic applications across structural, catalytic, and electronic domains. As research continues to reveal the mechanisms behind low-temperature nucleation and grain evolution, nano alumina is poised to play an even more central role in next-generation ceramic technologies.

Looking for a high-quality ceramic powder product? Contactez-nous dès aujourd'hui !