Soft Magnetic Alloy Powder 2025: Advanced Materials for High-Efficiency Magnetic Applications

Overview

Soft magnetic alloy powder is a specialized material designed for high-performance electromagnetic applications, including electric motors, transformers, inductors, and wireless charging systems. These powders exhibit high permeability, low coercivity, and low core loss, making them ideal for high-frequency applications and energy-efficient designs.

With the growing demand for lightweight, energy-efficient electrical components, soft magnetic alloy powders are revolutionizing industries such as automotive (EV motors), aerospace, telecommunications, and power electronics.

At Heeger Materials Inc., we specialize in high-purity, custom soft magnetic alloy powders optimized for advanced electromagnetic applications.

Why Choose Soft Magnetic Alloy Powder?

Soft magnetic powders are essential for optimizing electromagnetic performance in modern applications where energy efficiency, miniaturization, and high-power density are critical.

Key Benefits

- High Magnetic Permeability – Enhances flux conduction in electromagnetic components.

- Low Coercivity – Reduces energy loss and hysteresis.

- Low Core Loss – Improves efficiency in high-frequency applications.

- Excellent Thermal Stability – Ensures consistent performance under varying operating conditions.

- Customizable Particle Size & Composition – Tailored for specific applications such as high-speed motors and power inductors.

Looking for optimized soft magnetic alloy powders? Explore Heeger Materials’ selection.

Related Products

-

Fe54Cr25Mo16B2C2.6 Soft Magnetic Alloy Spherical Powder – Fe54Cr25Mo16B2C2.6 Powder – Additive Manufacturing – 3D Printing

-

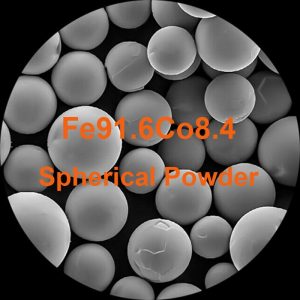

Fe91.6Co8.4 Soft Magnetic Alloy Spherical Powder – Fe91.6Co8.4 Powder – Additive Manufacturing – 3D Printing

-

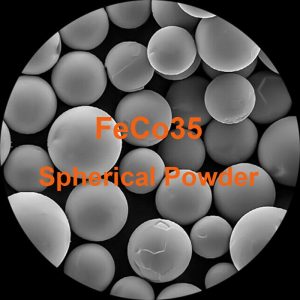

FeCo35 Soft Magnetic Alloy Spherical Powder – FeCo35 Powder – Additive Manufacturing – 3D Printing

-

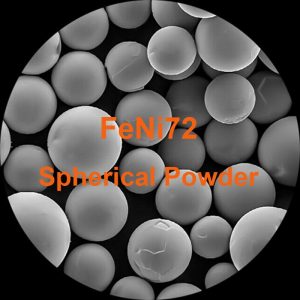

FeNi72 Soft Magnetic Alloy Spherical Powder – FeNi72 Powder – Additive Manufacturing – 3D Printing

Common Types

Different soft magnetic alloys are optimized for specific applications based on their composition, permeability, and core loss characteristics.

Comparison

| Alloy Type | Key Properties | Common Applications |

|---|---|---|

| Iron-Silicon (Fe-Si) Alloy | High electrical resistivity, low core loss | Transformers, electric motors |

| Iron-Nickel (Fe-Ni) Alloy (Permalloy) | High permeability, low coercivity | Magnetic shielding, sensors, inductors |

| Iron-Cobalt (Fe-Co) Alloy | High saturation magnetization, superior power density | Aerospace, high-speed motors |

| Soft Ferrite Powders (MnZn, NiZn Ferrites) | High resistivity, used in high-frequency applications | Inductors, transformers, wireless charging |

| Amorphous & Nanocrystalline Magnetic Powders | Ultra-low core loss, high-frequency efficiency | High-efficiency power electronics, electric vehicle (EV) components |

Iron-Silicon and Iron-Nickel alloys dominate power electronics and transformers, while Iron-Cobalt alloys are preferred for high-performance aerospace and defense applications.

Request a custom quote for soft magnetic alloy powders.

Applications of Soft Magnetic Alloy Powder in Industry

Soft magnetic powders are shaping the future of electromagnetic and energy-efficient applications.

Key Industrial Applications

| Industry | Application | Advantages |

|---|---|---|

| Automotive (EV Motors) | High-efficiency electric motors | Lower energy loss, higher torque density |

| Power Electronics | Inductors, transformers | Improved power efficiency, reduced heat generation |

| Aerospace & Defense | High-speed actuators, magnetic shielding | Lightweight, high-performance materials |

| Renewable Energy | Wind turbine generators | Enhanced energy conversion efficiency |

| Telecommunications | Wireless charging systems, filters | High-frequency stability, miniaturization |

With the rise of electric vehicles (EVs) and renewable energy, soft magnetic alloy powders are playing a crucial role in power conversion and motor efficiency.

Discover our high-performance soft magnetic powders.

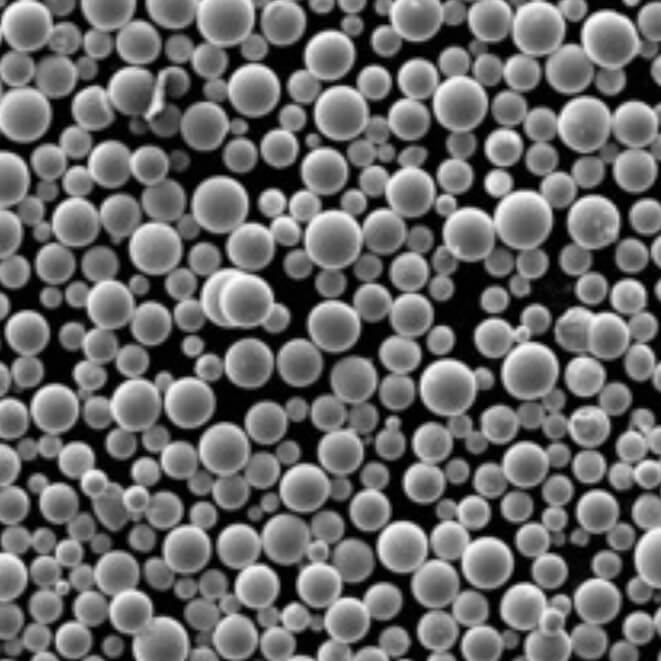

Particle Size and Shape in Soft Magnetic Alloy Powders

The particle size distribution (PSD) and morphology significantly impact magnetic performance, permeability, and core loss.

Optimal Particle Size for Soft Magnetic Applications

| Particle Size Range | Best Application |

|---|---|

| 1-10 µm | High-frequency inductors, transformers |

| 10-45 µm | Electromagnetic shielding, sensors |

| 45-150 µm | Electric motors, power electronics |

Spherical vs. Irregular Powder: Which is Better?

| Powder Shape | Characteristics | Best Application |

|---|---|---|

| Spherical | Better packing density, improved permeability, lower eddy current loss | High-frequency applications, power electronics |

| Irregular | Higher surface area, lower cost | Magnetic shielding, general-purpose applications |

Spherical soft magnetic powders are preferred for high-frequency and high-efficiency applications, ensuring superior magnetic properties.

Explore our optimized soft magnetic alloy powders.

Top Suppliers of Soft Magnetic Alloy Powders in 2025

Finding a reliable supplier is crucial for consistent soft magnetic alloy powder quality and performance.

Leading Soft Magnetic Alloy Powder Suppliers

| Supplier Name | Country | Specialization | Production Methods | Website |

|---|---|---|---|---|

| Heeger Materials Inc. | USA | Soft Magnetic Alloy Powders | VIGA, PREP, Gas Atomization | Visit Site |

| Höganäs | Sweden | Soft Magnetic Powders | Water Atomization | N/A |

| Hitachi Metals | Japan | High-Performance Magnetic Materials | Gas Atomization | N/A |

| VAC Group | Germany | Amorphous & Nanocrystalline Powders | Gas Atomization | N/A |

Heeger Materials Inc. specializes in customized soft magnetic alloy powders, delivering high-quality, high-performance materials for electromagnetic applications.

Contact Heeger Materials for premium soft magnetic powders.

Quality Standards for Soft Magnetic Alloy Powders

Ensuring high-quality soft magnetic alloy powders is crucial for efficient energy conversion, reduced core loss, and improved electromagnetic performance. Various international standards regulate the composition, particle size, and magnetic properties of these powders to meet aerospace, automotive, and industrial requirements.

Key Quality Standards for Soft Magnetic Alloy Powders

| Standard | Description |

|---|---|

| ASTM A804 | Standard for iron-based soft magnetic alloys. |

| ASTM A839 | Specification for Iron-Cobalt-Vanadium soft magnetic alloys. |

| IEC 60404-8-6 | Classification of Fe-Si soft magnetic powders. |

| ISO 3934 | Guidelines for powder metallurgy soft magnetic materials. |

| JIS C 2524 | Japan’s standard for soft magnetic core materials. |

| RoHS Compliance | Ensures environmental safety by limiting hazardous substances. |

Why Choose Certified Soft Magnetic Alloy Powders?

- Ensures Consistent Magnetic Properties – Maintains uniform permeability and low coercivity.

- Optimized for High-Frequency Applications – Minimizes eddy current losses in transformers and inductors.

- High-Purity Powders – Reduces impurities that degrade magnetic performance.

- Compliance with Automotive & Aerospace Standards – Ensures safety and efficiency in electric motor applications.

At Heeger Materials Inc., we manufacture high-purity soft magnetic powders that comply with ASTM, ISO, and IEC standards, ensuring optimal electromagnetic performance.

Cost Analysis of Soft Magnetic Alloy Powders

The price of soft magnetic alloy powders depends on material composition, production method, and application requirements.

Factors Affecting Soft Magnetic Alloy Powder Cost

- Material Composition – Iron-Cobalt and Nanocrystalline alloys are more expensive than Fe-Si and Fe-Ni alloys.

- Production Method – Gas atomization and Plasma atomization produce higher-quality spherical powders, increasing costs.

- Particle Size Distribution (PSD) – Finer powders (1-10µm) for high-frequency applications are more expensive due to higher processing precision.

- Magnetic Purity – Lower impurities and controlled oxygen content improve performance but increase production costs.

- Global Supply & Demand – Prices fluctuate based on raw material availability and industry trends.

Price Comparison of Soft Magnetic Alloy Powders

| Alloy Type | Cost ($/kg) | Common Use Case |

|---|---|---|

| Fe-Si (Iron-Silicon) Alloy | 50−50 – 50−150 | Transformers, electric motors |

| Fe-Ni (Permalloy) Alloy | 100−100 – 100−300 | Magnetic shielding, sensors |

| Fe-Co (Iron-Cobalt) Alloy | 300−300 – 300−700 | Aerospace, high-speed motors |

| Nanocrystalline Magnetic Powders | 500−500 – 500−1,200 | High-frequency power electronics |

| Soft Ferrite Powders | 30−30 – 30−100 | Inductors, wireless charging |

Nanocrystalline and Fe-Co alloys are more expensive due to their superior high-frequency efficiency and power density, while Fe-Si and ferrite powders offer cost-effective solutions for industrial applications.

Request a custom price quote for bulk orders.

Production Methods for Soft Magnetic Alloy Powders

Different powder production techniques impact the particle shape, purity, and cost of soft magnetic alloy powders.

Comparison of Powder Production Methods

| Production Method | Particle Shape | Purity | Cost | Best Use Case |

|---|---|---|---|---|

| Gas Atomization (GA) | Spherical | High | $$$ | Electric motors, transformers |

| Plasma Atomization (PA) | Highly Spherical | Very High | $$$$ | High-frequency inductors, aerospace applications |

| Water Atomization (WA) | Irregular | Moderate | $$ | Magnetic shielding, general applications |

| Mechanical Milling | Flake-Like | Moderate | $$ | Magnetic cores, sensors |

Gas atomization and plasma atomization methods are preferred for high-performance electromagnetic applications, ensuring excellent purity, sphericity, and magnetic performance.

Heeger Materials Inc. specializes in gas-atomized and plasma-atomized soft magnetic powders, delivering high-quality materials for advanced applications.

FAQ About Soft Magnetic Alloy Powders

| Question | Answer |

|---|---|

| What are soft magnetic alloy powders used for? | They are used in electric motors, transformers, inductors, and magnetic shielding for high-efficiency electromagnetic applications. |

| What is the best soft magnetic material for high-frequency applications? | Nanocrystalline and amorphous magnetic powders offer ultra-low core loss and excellent high-frequency performance. |

| What is the difference between Fe-Si and Fe-Ni soft magnetic alloys? | Fe-Si alloys provide low core loss and high electrical resistivity, while Fe-Ni alloys (Permalloy) offer high permeability and low coercivity. |

| What is the typical particle size for soft magnetic powders? | 1-10 µm for high-frequency applications, 10-45 µm for shielding, and 45-150 µm for electric motors. |

| Where can I buy high-quality soft magnetic alloy powder? | Heeger Materials Inc. provides premium soft magnetic powders for industrial applications. |

Conclusion

Soft magnetic alloy powders are driving innovations in electromagnetic applications, enabling higher energy efficiency, improved performance, and miniaturization in industries like EV motors, power electronics, and aerospace.

For top-quality soft magnetic alloy powders, Heeger Materials Inc. provides tailored solutions with high-purity, gas-atomized spherical powders.

Looking for premium soft magnetic alloy powder? Contact us today!