Metal 3D Printing 2025: The Future of Additive Manufacturing

Overview of Metal 3D Printing

Metal 3D printing, also known as metal additive manufacturing (AM), is revolutionizing industries by enabling the production of complex, high-performance metal parts with reduced material waste, improved efficiency, and enhanced design freedom. This technology is widely used in aerospace, medical, automotive, and industrial applications where traditional manufacturing methods fall short.

By utilizing advanced metal powders, metal 3D printing allows for the production of lightweight, high-strength, and heat-resistant components, making it a key driver of next-generation manufacturing.

At Heeger Materials Inc., we specialize in high-quality metal powders optimized for various 3D printing processes, ensuring superior printability and mechanical performance.

Why Choose Metal 3D Printing?

Metal 3D printing offers unmatched advantages over traditional manufacturing, making it ideal for prototyping, production, and customization.

Key Benefits of Metal 3D Printing

- Complex Geometries & Lightweight Structures – Enables designs that are impossible with conventional machining.

- Reduced Material Waste – Unlike subtractive manufacturing, metal 3D printing minimizes waste by using only the required material.

- Superior Mechanical Properties – Parts exhibit high strength, durability, and heat resistance.

- Customization & Rapid Production – Ideal for low-volume, high-value production runs.

- Efficient Supply Chains – Reduces lead times and logistics costs.

Looking for high-performance metal powders for 3D printing? Explore Heeger Materials’ selection.

Related Products

-

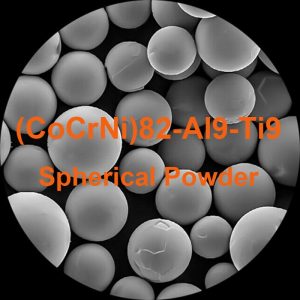

(CoCrNi)82-Al9-Ti9 High-entropy Alloy Spherical Powder – (CoCrNi)82-Al9-Ti9 HEA – Additive Manufacturing – 3D Printing

-

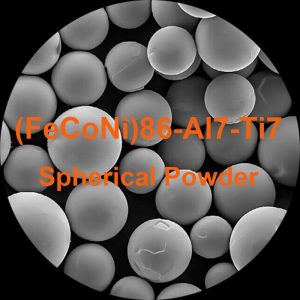

(FeCoNi)86-Al7-Ti7 High-entropy Alloy Spherical Powder – (FeCoNi)86-Al7-Ti7 HEA – Additive Manufacturing – 3D Printing

-

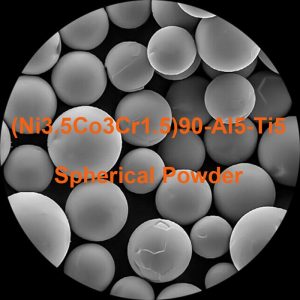

(Ni3.5Co3Cr1.5)90-Al5-Ti5 High-entropy Alloy Spherical Powder – (Ni3.5Co3Cr1.5)90-Al5-Ti5 HEA – Additive Manufacturing – 3D Printing

-

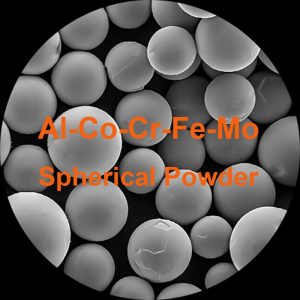

Al-Co-Cr-Fe-Mo High-entropy Alloy Spherical Powder – Al-Co-Cr-Fe-Mo HEA – Additive Manufacturing – 3D Printing

Best Metal Powders for 3D Printing

Selecting the right metal powder is crucial for printability, mechanical properties, and final part performance.

Comparison of Metal Powders for 3D Printing

| Metal Powder | Key Properties | Best Applications |

|---|---|---|

| Titanium Alloys (Ti6Al4V) | Lightweight, high strength, biocompatible | Aerospace, medical implants |

| Nickel-Based Alloys (Inconel 625, 718) | High-temperature resistance, corrosion resistance | Aerospace, energy, automotive |

| Cobalt-Based Alloys (Stellite, CoCrMo) | Wear and oxidation resistance | Medical, dental, industrial tooling |

| Stainless Steel (316L, 17-4PH) | High strength, corrosion resistance | Industrial, marine, medical |

| Aluminum Alloys (AlSi10Mg, Al7075) | Lightweight, good thermal conductivity | Automotive, aerospace |

| Copper & Copper Alloys | High thermal & electrical conductivity | Electronics, heat exchangers |

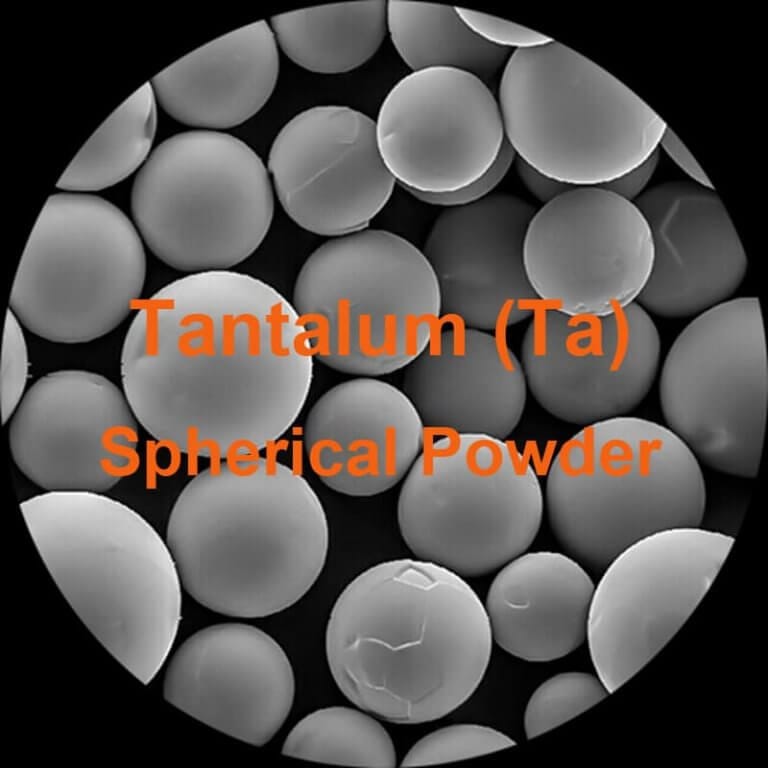

| Tungsten & Refractory Metals | High density, extreme heat resistance | Defense, nuclear, aerospace |

Nickel-based alloys and titanium powders are preferred for high-performance applications, while stainless steel and aluminum powders offer cost-effective solutions.

Request a custom quote for metal 3D printing powders.

Metal 3D Printing Technologies

Different 3D printing technologies are used for metal additive manufacturing, each with unique advantages and material compatibility.

Comparison of Metal 3D Printing Processes

| 3D Printing Method | Process Type | Best Materials | Key Benefits |

|---|---|---|---|

| Laser Powder Bed Fusion (LPBF/SLM/DMLS) | Powder-based | Titanium, Nickel, Stainless Steel | High precision, fine details |

| Electron Beam Melting (EBM) | Powder-based | Titanium, Cobalt-Chrome | High-temperature processing, bulk production |

| Binder Jetting | Powder-based | Stainless Steel, Bronze | Cost-effective, large-scale production |

| Directed Energy Deposition (DED/LMD) | Wire or Powder-based | Nickel, Titanium, Stainless Steel | Repair & hybrid manufacturing |

| Metal Binder Jetting | Powder-based | Stainless Steel, Copper | Low-cost, high-volume production |

LPBF (SLM/DMLS) and EBM are the most widely used for high-performance aerospace and medical applications, while Binder Jetting and DED are ideal for cost-effective mass production.

Find the best metal powder for your 3D printing process.

Applications of Metal 3D Printing in Industry

Metal 3D printing is transforming industries by enabling lightweight, high-performance, and cost-effective components.

Key Industrial Applications

| Industry | Application | Advantages |

|---|---|---|

| Aerospace & Defense | Lightweight structural components, turbine blades | High-performance, reduced weight |

| Automotive | Custom engine parts, lightweight components | Improved fuel efficiency, rapid prototyping |

| Medical & Dental | Patient-specific implants, prosthetics | Biocompatibility, precision manufacturing |

| Energy & Power Generation | Heat exchangers, gas turbines | High-temperature resistance, durability |

| Industrial Tooling | Molds, dies, wear-resistant coatings | Extended tool life, cost savings |

With the rise of electric vehicles (EVs) and advanced aerospace components, metal 3D printing is driving next-generation manufacturing innovations.

Discover our high-performance metal 3D printing powders.

Quality Standards for Metal 3D Printing Powders

To ensure reliable and repeatable printing, metal powders must comply with strict quality standards.

Key Quality Standards for Metal 3D Printing Powders

| Standard | Description |

|---|---|

| ASTM F3049 | Standard for metal powder characterization in additive manufacturing. |

| ASTM F3302 | Specification for metal powders used in powder bed fusion (PBF) AM processes. |

| ISO 52907 | Guidelines for quality control of powders used in additive manufacturing. |

| AMS 4999 | Aerospace Material Specification for nickel and titanium powders. |

| RoHS Compliance | Ensures environmental safety by limiting hazardous substances. |

At Heeger Materials Inc., we manufacture high-purity metal powders that comply with ASTM, ISO, and AMS standards, ensuring excellent printability and mechanical performance.

Cost Analysis of Metal 3D Printing Powders

The cost of metal 3D printing powders varies based on material composition, production method, and industry demand. High-performance alloys such as titanium, nickel-based superalloys, and cobalt-based powders tend to be more expensive due to their advanced mechanical properties and processing requirements.

Factors Affecting Metal 3D Printing Powder Cost

- Material Composition – Exotic alloys (Titanium, Inconel, Cobalt-Chrome) are more expensive than stainless steel or aluminum powders.

- Production Method – Gas atomization and plasma atomization produce highly spherical, high-purity powders, increasing costs.

- Particle Size Distribution (PSD) – Finer powders (15-45µm) for LPBF are more expensive due to precision requirements.

- Purity & Oxygen Content – Lower oxygen levels improve mechanical properties but increase production costs.

- Market Demand & Supply – Prices fluctuate based on raw material availability, industry trends, and geopolitical factors.

Price Comparison of Metal 3D Printing Powders

| Metal Powder Type | Cost ($/kg) | Common Applications |

|---|---|---|

| Titanium Alloy (Ti6Al4V) | 300−300 – 300−700 | Aerospace, medical implants |

| Nickel-Based Superalloy (Inconel 625, 718) | 350−350 – 350−900 | High-temperature aerospace components |

| Cobalt-Chrome Alloy (CoCrMo) | 250−250 – 250−600 | Medical implants, dental applications |

| Stainless Steel (316L, 17-4PH) | 80−80 – 80−250 | Industrial, marine, medical |

| Aluminum Alloy (AlSi10Mg, Al7075) | 80−80 – 80−250 | Automotive, aerospace |

| Copper & Copper Alloys | 100−100 – 100−500 | Electronics, heat exchangers |

| Tungsten & Refractory Metal Powders | 400−400 – 400−1,200 | Defense, nuclear, aerospace |

Titanium and nickel-based alloys are preferred for high-performance applications, while stainless steel and aluminum powders offer cost-effective solutions for industrial use.

Request a customized quote for bulk orders.

Production Methods for Metal 3D Printing Powders

Different powder production techniques impact the particle shape, purity, and cost of metal 3D printing powders.

Comparison of Powder Production Methods

| Production Method | Particle Shape | Purity | Cost | Best Use Case |

|---|---|---|---|---|

| Gas Atomization (GA) | Spherical | High | $$$ | LPBF, EBM, Binder Jetting |

| Plasma Atomization (PA) | Highly Spherical | Very High | $$$$ | Medical, aerospace applications |

| Water Atomization (WA) | Irregular | Moderate | $$ | Binder Jetting, MIM |

| Plasma Rotating Electrode Process (PREP) | Extremely Spherical | Ultra-High | $$$$$ | High-performance aerospace & medical applications |

Gas atomization and plasma atomization are the most widely used methods for high-quality metal 3D printing powders, ensuring excellent purity, sphericity, and printability.

Heeger Materials Inc. specializes in gas-atomized and plasma-atomized metal powders, delivering superior quality and consistency.

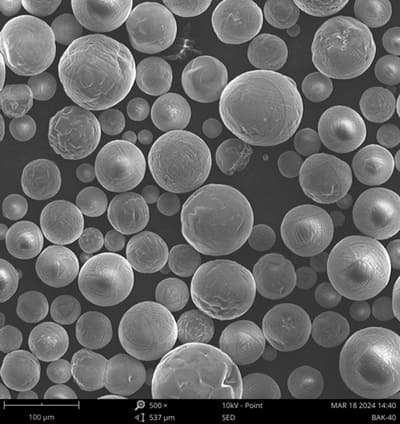

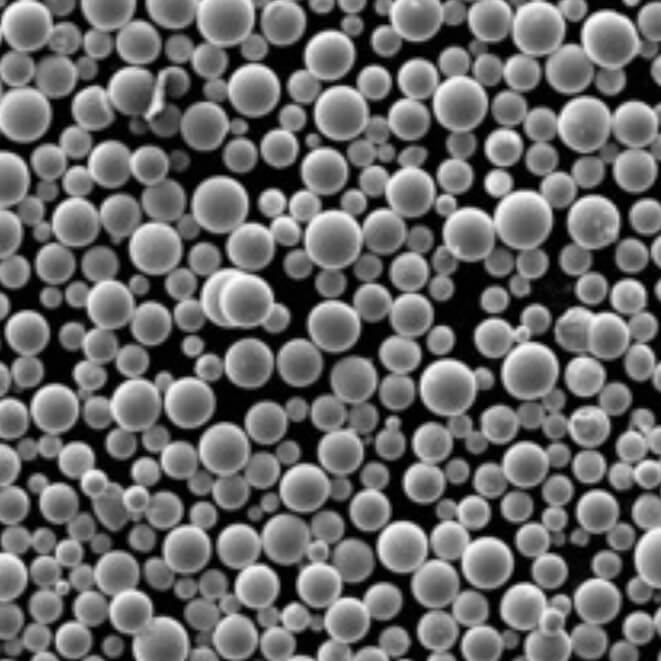

Particle Size and Shape in Metal 3D Printing Powders

The particle size distribution (PSD) and morphology play a key role in powder flowability, packing density, and final part quality in metal 3D printing processes.

Optimal Particle Size for Metal 3D Printing Applications

| Particle Size Range | Best Application |

|---|---|

| 15-45 µm | Laser Powder Bed Fusion (LPBF, SLM, DMLS) |

| 45-75 µm | Electron Beam Melting (EBM), Directed Energy Deposition (DED) |

| 75-150 µm | Binder Jetting, Metal Injection Molding (MIM) |

Spherical vs. Irregular Powder: Which is Better?

| Powder Shape | Characteristics | Best Application |

|---|---|---|

| Spherical | Excellent flowability, uniform packing, high printability | LPBF, EBM, Binder Jetting |

| Irregular | Lower flowability, rougher surface finish, lower cost | Binder Jetting, MIM |

Spherical powders are preferred for metal additive manufacturing, ensuring better flowability, uniform layering, and minimal defects.

Explore our high-quality spherical metal powders.

Top Suppliers in 2025

Finding a reliable supplier is crucial for consistent quality, repeatability, and performance in metal 3D printing.

Leading Suppliers

| Supplier Name | Country | Specialization | Production Methods | Website |

|---|---|---|---|---|

| Heeger Materials Inc. | USA | Metal 3D Printing Powders | VIGA, PREP, Gas Atomization | Visit Site |

| Höganäs | Sweden | Metal Powders for AM | Water Atomization | N/A |

| Oerlikon Metco | Switzerland | Aerospace & Industrial 3D Printing Powders | Gas Atomization | N/A |

| Sandvik | Sweden | Hardfacing & Wear-Resistant Powders | Gas Atomization | N/A |

Looking for high-performance metal 3D printing powders? Contact Heeger Materials today!.

FAQ

| Question | Answer |

|---|---|

| What is metal 3D printing used for? | It is used for aerospace, medical, automotive, and industrial applications requiring high-performance metal parts. |

| What is the best metal for 3D printing aerospace parts? | Titanium alloys (Ti6Al4V) and nickel-based superalloys (Inconel 625, 718) are preferred for high-temperature and lightweight applications. |

| Which 3D printing method is best for metal parts? | Laser Powder Bed Fusion (LPBF) and Electron Beam Melting (EBM) offer high precision and excellent mechanical properties. |

| What is the typical particle size for metal 3D printing powders? | 15-45 µm for LPBF, 45-75 µm for EBM, and 75-150 µm for Binder Jetting. |

| Where can I buy high-quality metal 3D printing powder? | Heeger Materials Inc. provides premium metal powders for additive manufacturing. |

Conclusion

Metal 3D printing is revolutionizing manufacturing across industries, enabling lightweight, high-strength, and complex geometries that traditional methods cannot achieve.

For top-quality metal 3D printing powders, Heeger Materials Inc. provides tailored solutions with high-purity, gas-atomized spherical powders.

Looking for premium metal 3D printing powder? Contact us today!